Method for retaining vertical impact of impacting mechanism and vertical-lift impact-cutting digger implementing same

A technology of a vertical lifting mechanism and an impact mechanism, applied in the field of machinery, can solve the problems of difficulty in realizing coal mining by turning the impact head back, reducing efficiency, and increasing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

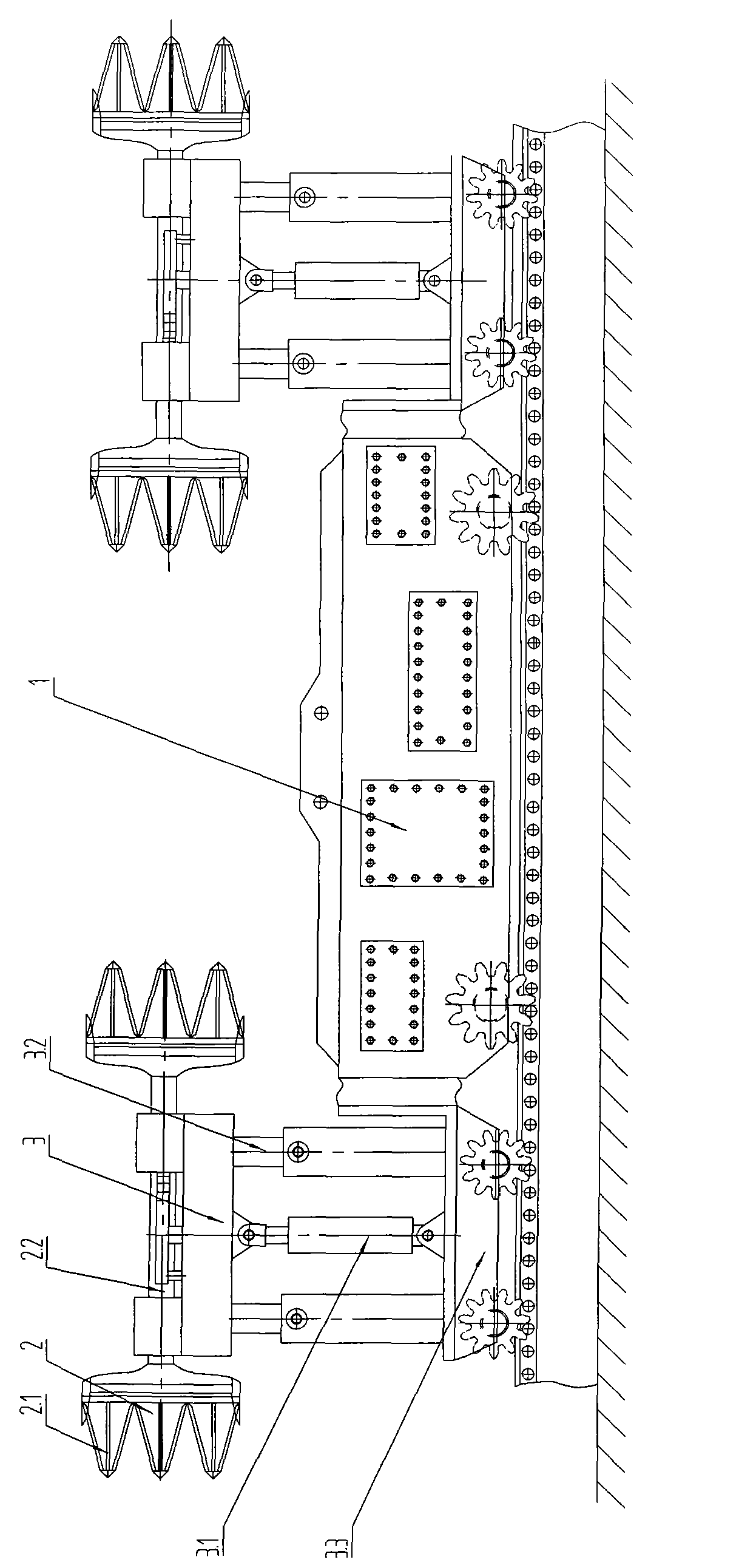

[0104] figure 1 It is the vertical lift punching excavator described in Embodiment 1. The vertical lifting punching mining machine includes a fuselage 1, an impact mechanism 2 and a vertical lifting mechanism 3. The impact mechanism 2 includes an impact head 2.1 and an impact guide 2.2. The vertical lifting mechanism 3 includes a vertical lifting drive device 3.1, a lifting moving part 3.2 and The supporting base 3.3, the lifting moving part 3.2 is movably connected with the supporting base 3.3, the supporting base 3.3 is connected with the fuselage 1, the impact mechanism 2 is arranged on the lifting moving part 3.2, the vertical lifting driving device 3.1 drives the lifting moving part 3.2 to move vertically up and down, and the lifting The moving part 3.2 drives the impact mechanism 2 to lift vertically.

Embodiment 2

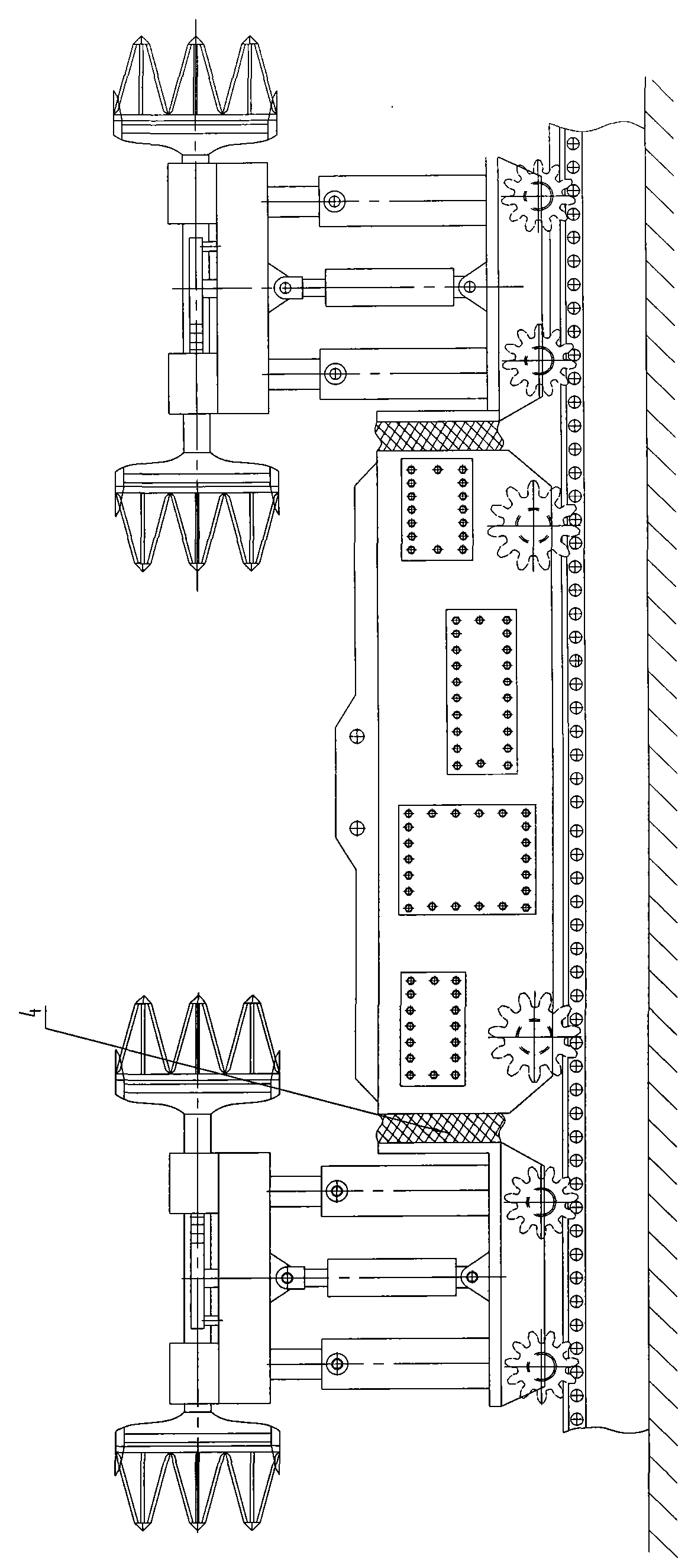

[0106] figure 2 It is the vertical lifting mechanism of the vertical lifting punching mining machine described in embodiment 2. What the vertical lifting driving device 3.1 of this vertical lifting mechanism 3 adopted is a spiral vertical lifting driving device.

[0107] Others are the same as embodiment 1.

Embodiment 3

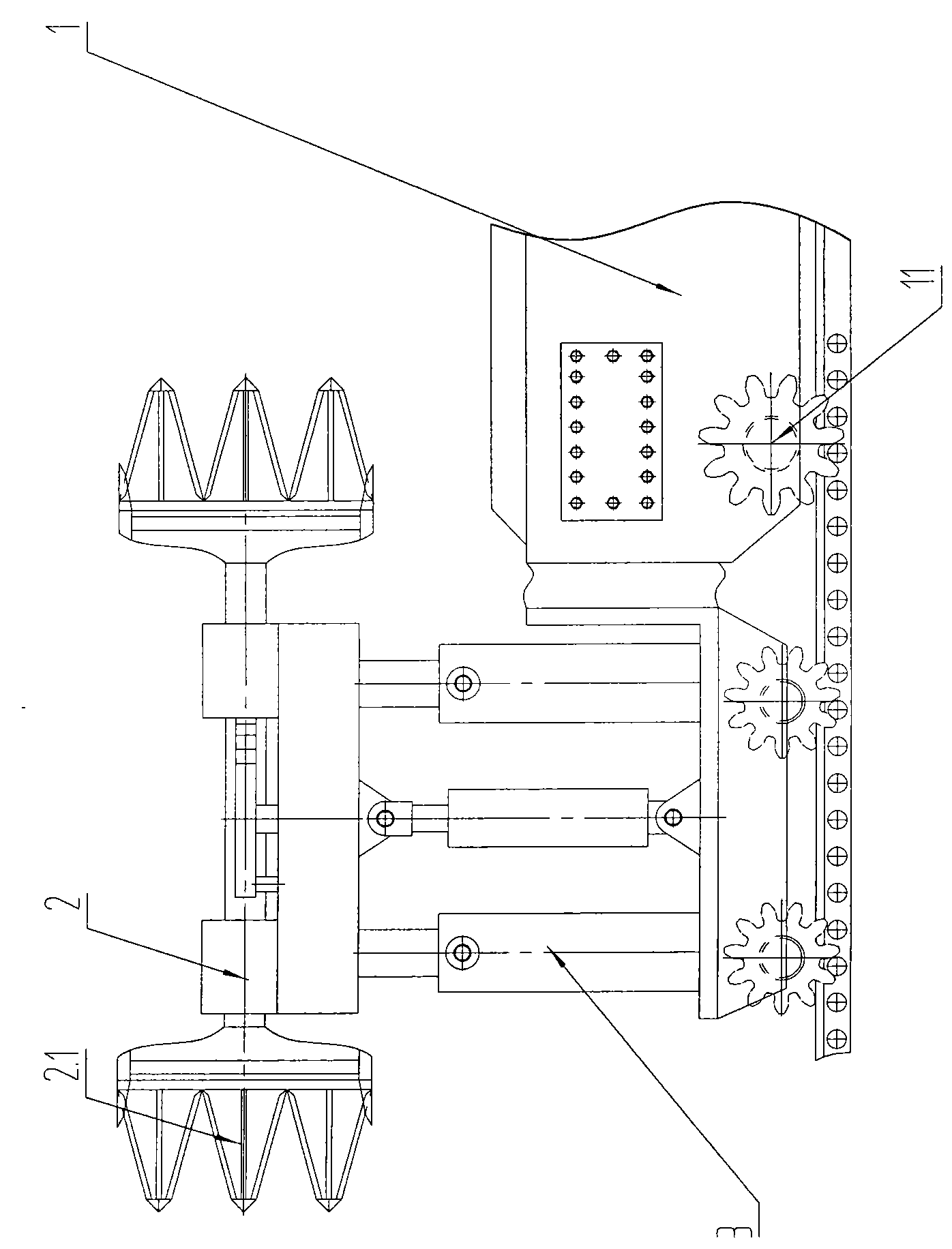

[0109] image 3 It is the vertical lifting mechanism of the vertical lifting punching mining machine described in embodiment 3. What the vertical lifting driving device 3.1 of this vertical lifting mechanism 3 adopted is the vertical lifting driving device of rope and rope reel.

[0110] The vertical lift drive device 3.1 can also be a hydraulic vertical lift drive device, a buckle lift device, a pneumatic vertical lift drive device, a sprocket chain vertical lift drive device or a rack and pinion vertical lift drive device.

[0111] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com