Food processor and knife group mounting structure and stirring cup thereof

A food cooking machine and installation structure technology, which is applied in the field of household electrical appliances, can solve the problems of time-consuming and laborious, inconvenient disassembly and assembly, and achieve the effects of avoiding time-consuming and laborious, reducing operating strength, and improving the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

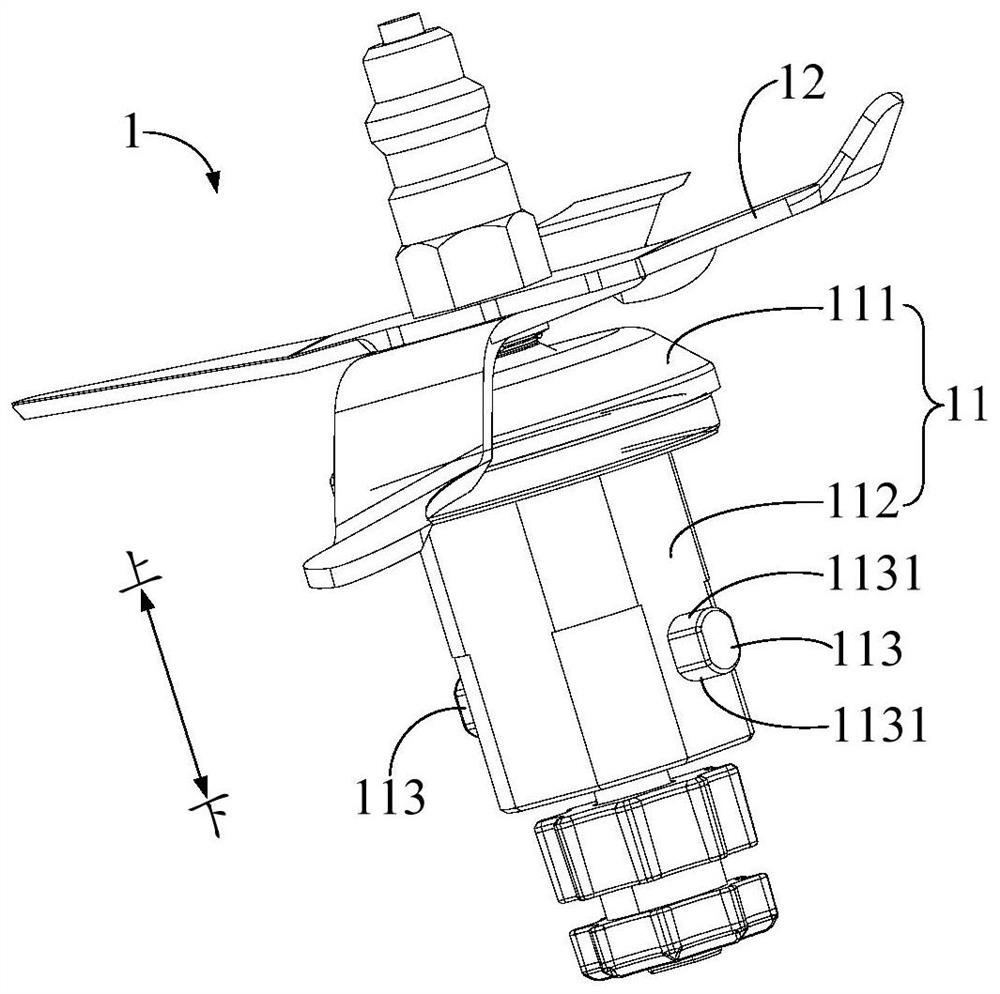

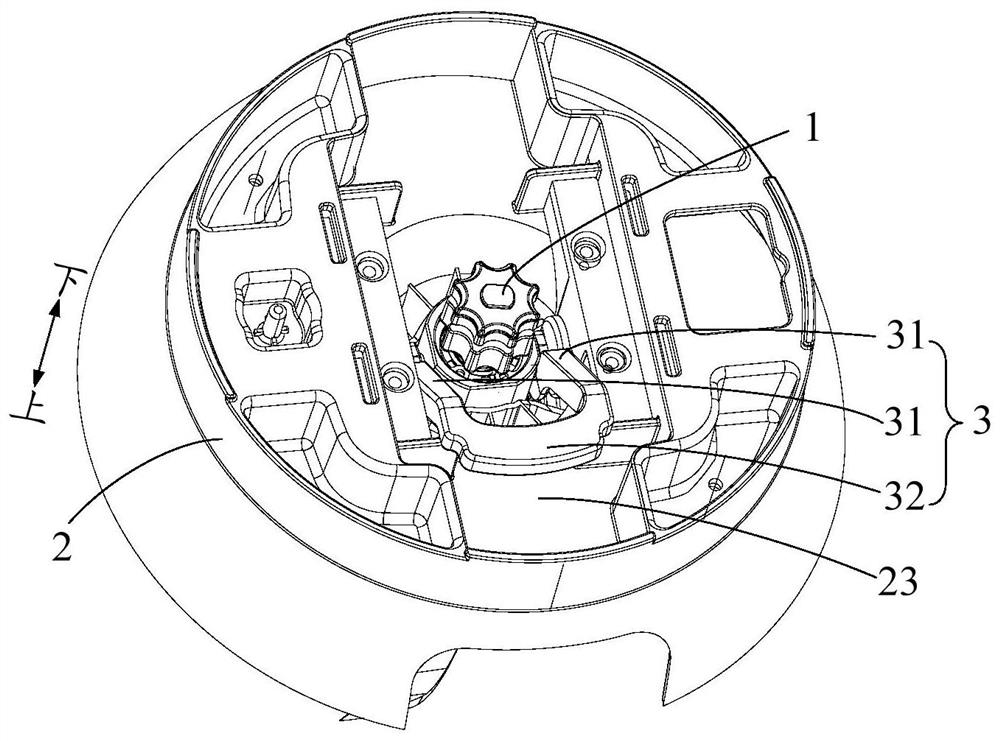

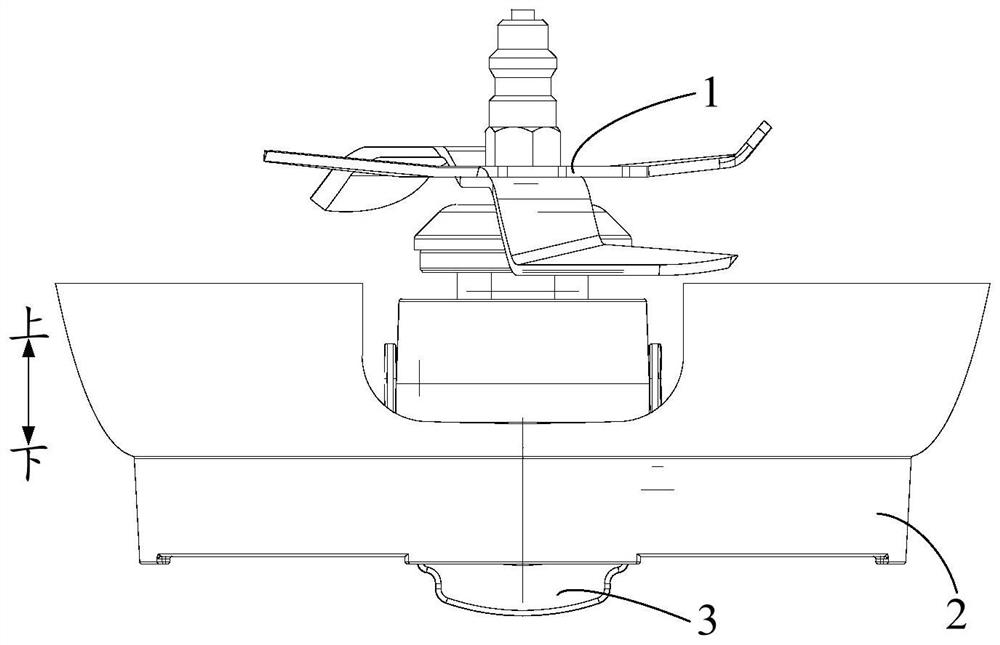

[0099] Such as figure 2 , image 3 with Figure 4 As shown, the knife set installation structure of the food cooking machine provided by the embodiment of the first aspect of the present invention includes: a container bottom 2, a knife seat 11 and a locking component.

[0100] Specifically, the bottom wall of the container bottom 2 is provided with a mounting hole 24, such as Figure 13 As shown; the knife seat 11 is installed at the installation hole 24 for installing the knife 12 of the food cooking machine; the locking part is installed on the bottom 2 of the container, matched with the knife seat 11, and is suitable for removing the knife relative to the bottom 2 of the container Reciprocate between the knife lock position, and lock the knife seat 11 to fix the knife seat 11 when moving to the knife lock position (such as Figure 5 with Image 6 shown), and unlock the knife seat 11 to release the knife seat 11 when moving to the knife removal position (such as Figu...

Embodiment 2

[0145] The difference with Embodiment 1 is: on the basis of Embodiment 1, further, the wrench 3 is provided with a limiter, and the bottom 2 of the container is provided with a limiter fit. Next, the limit part and the limit fit part are in contact with each other, such as Figure 9 with Figure 10 As shown, to limit the rotation range of the wrench 3.

[0146] The rotation range of the wrench 3 is limited by the stop fit of the limit part and the limit fit part, and a sense of in-position will be generated during the process of disassembling and assembling the knife set 1, so that it can play the role of assembly positioning, and at the same time, it can prevent the wrench 3 from After the rotation is in place, it continues to rotate, which improves the reliability of use.

[0147] Optionally, one of the limiting portion and the limiting fitting portion is a limiting protrusion 21, and the other is a limiting groove 315, such as Figure 9 with Figure 10 shown.

[0148] ...

Embodiment 3

[0160] The difference with Embodiment 2 is that: on the basis of Embodiment 2, further, the number of locking protrusions 113 is two, and the two locking protrusions 113 are arranged symmetrically at 180° with respect to the central axis of the tool holder 11, as figure 1 As shown, the number of locking grooves 311 is equal to the number of locking protrusions 113 and corresponds one by one; the wrench 3 is U-shaped, as figure 2 , Figure 5 with Figure 7 As shown, it includes two rotating arms 31 parallel to each other and a connecting arm 32 connecting the two rotating arms 31. The ends of the two rotating arms 31 away from the connecting arms 32 are rotationally connected to the bottom 2 of the container, and the two rotating arms 31 are respectively A locking protrusion 113 or a locking groove 311 is provided.

[0161] The number of locking protrusions 113 is two, and the two locking protrusions 113 are arranged symmetrically at 180° with respect to the central axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com