Electric discharge machine and method of electric discharge machining

A processing device and processing method technology, applied in the direction of electric processing equipment, selection device, metal processing equipment, etc., can solve problems such as difficulties, achieve the effects of improving processing accuracy, increasing processing speed, and shortening jumping action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

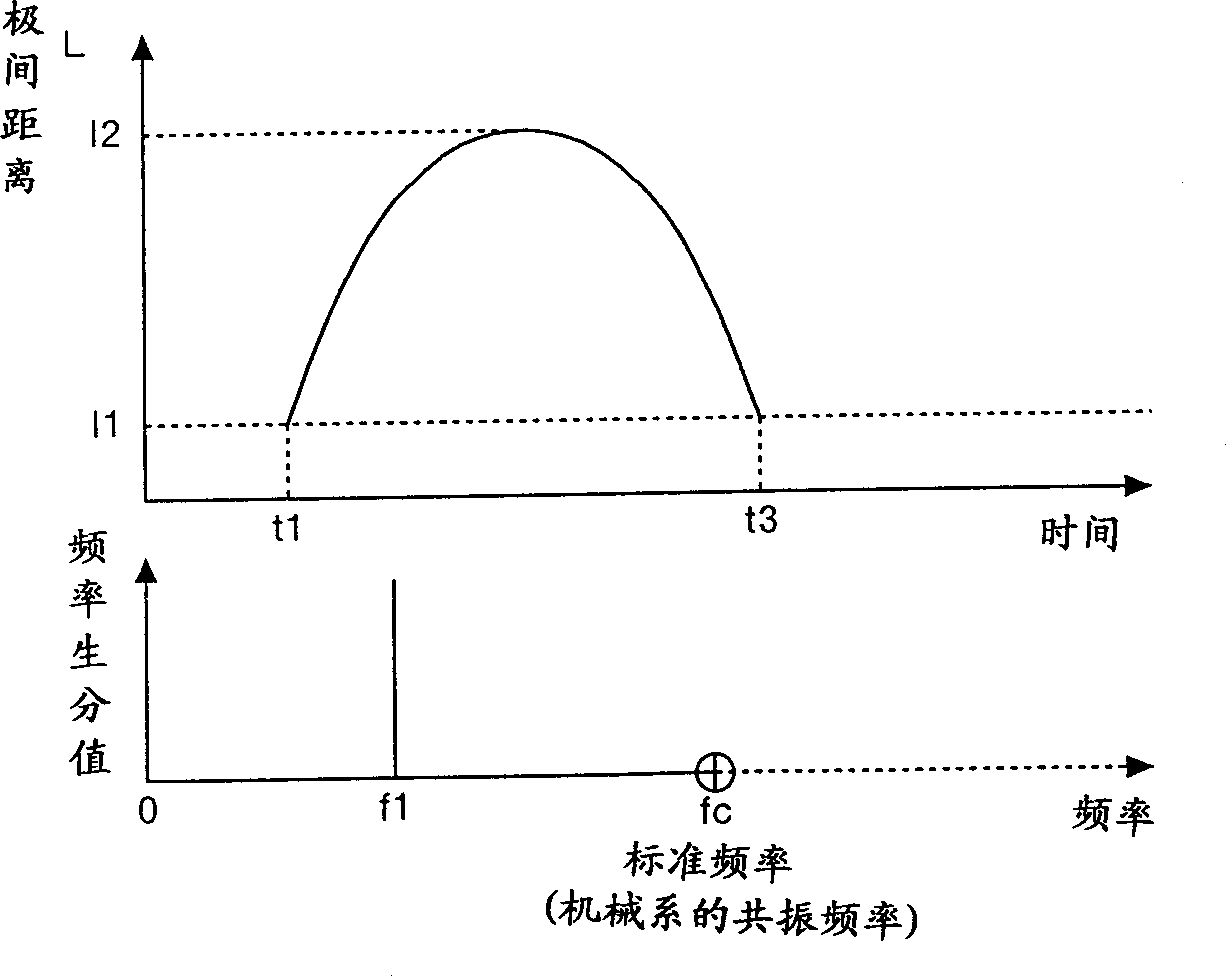

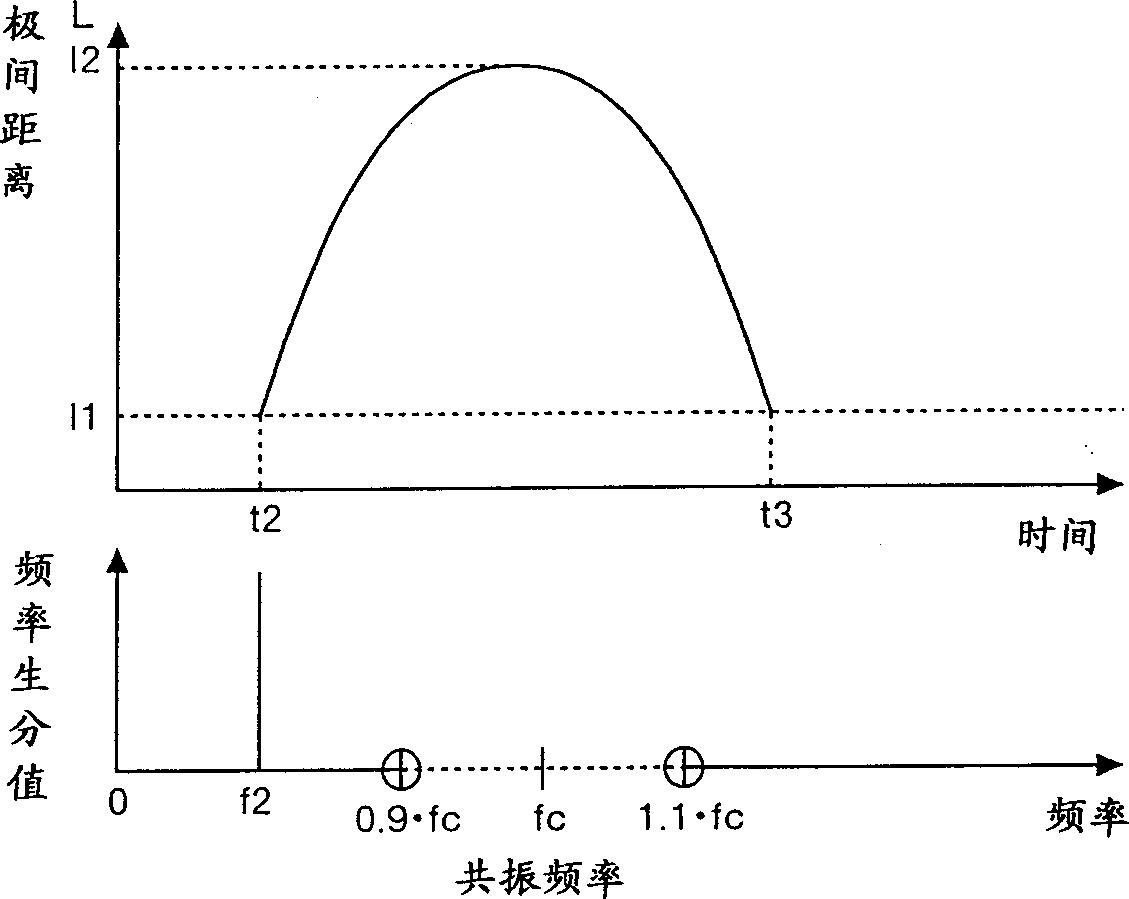

[0121] Embodiment 6 of the present invention will be described below. In the above-mentioned Embodiments 4 and 5, a command trajectory is generated by the jump generation unit 1, which suppresses the frequency component values in each frequency range to a predetermined value C or less. In this embodiment 6, a filter 15 is provided at the output stage of the jump control part 2, which is used to convert the resonance frequency f c Frequency component values in the above frequency range are suppressed to a predetermined value C or less.

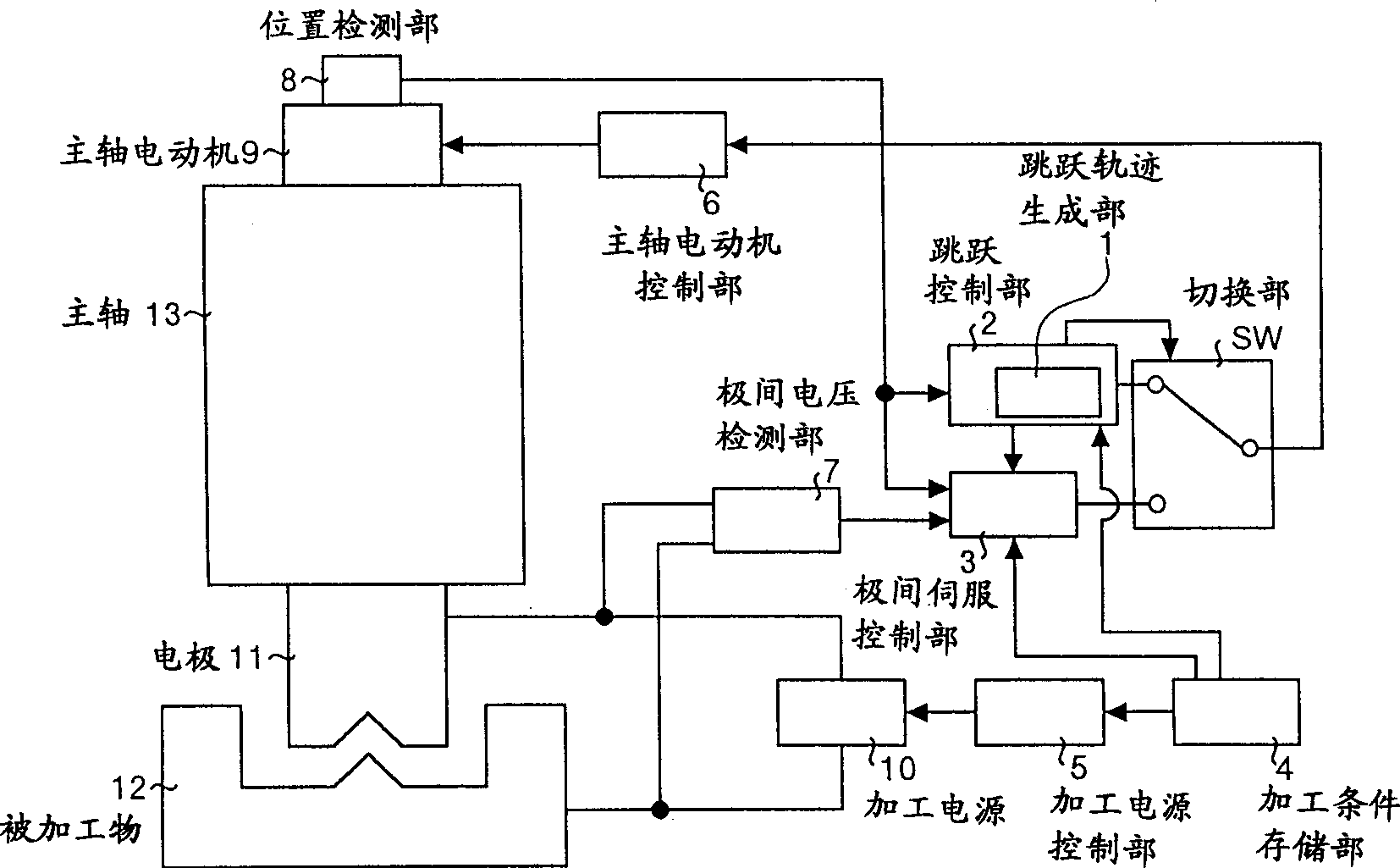

[0122] Figure 8 It is a block diagram showing the configuration of an electrical discharge machining apparatus according to an eighth embodiment of the present invention. exist Figure 8 Among them, the filter 15 is an analog filter, and the resonant frequency f c The frequency component values in the above frequency range are suppressed to a predetermined value C or less and output. Other composition and figure 1 The configuration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com