Rotary nut-picking manipulator and nut picking method

A technology for manipulators and nuts, which is applied in the field of twisting nut picking manipulators, can solve the problems that the roots of fruit trees are easily loosened by vibration, the secondary branches are broken by vibration, and the fruit trees are damaged, so as to achieve high picking efficiency, improve the reliability of use, and reduce the impact on fruit trees. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

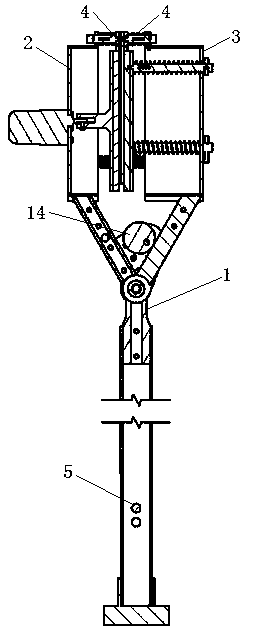

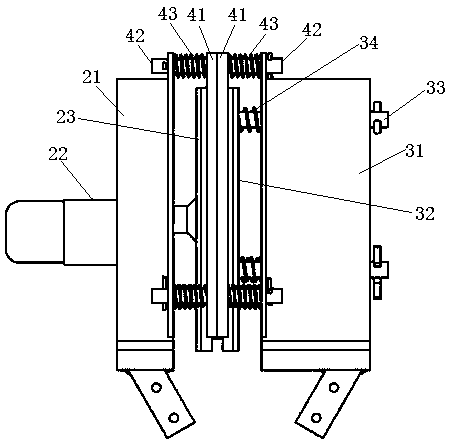

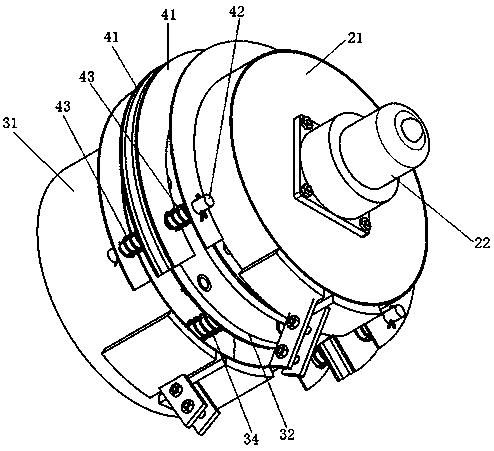

[0032] Combine below Figure 1 to Figure 5 The embodiments of the present invention will be described in detail.

[0033] The twisting nut picking manipulator includes a Y-shaped electric handle 1 that can be automatically opened and closed at the upper end. The coaxially opposite and non-contacting fruit clamping assemblies 3, the outer peripheries of the electric fruit twisting assembly 2 and the fruit clamping assembly 3 are equipped with branch clamping assemblies 4 respectively, and the two branch clamping assemblies 4 are coaxially oppositely arranged and Elastic contact, the electric fruit twisting assembly 2 and the fruit tightening assembly 3 are separated or approached with the opening and closing of the Y-shaped electric handle 1, and drive the two branch clamping assemblies 4 to separate or approach, and the branches connected with the fruit are clamped on the Between the two branch clamping components 4, the fruit is clamped between the electric fruit twisting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com