Cutting disc type rotating arm heading machine cutting device

A technology of rotating arms and cutting blades, which is applied in the field of gas, roadway roof treatment, and roadheader cutting devices. It can solve problems such as roof accidents, threats to the safety of shaft construction, and broken roadway roofs, so as to prevent roof accidents and protect the integrity of the roof. performance, and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

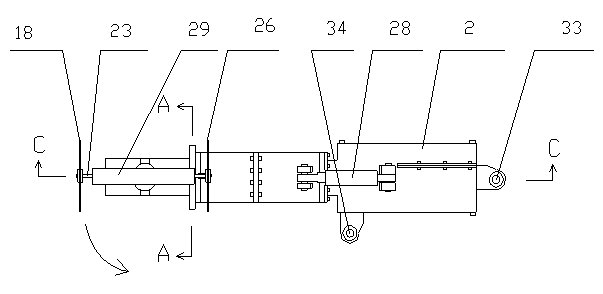

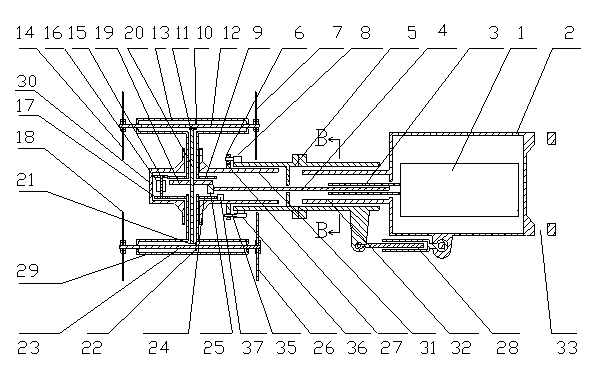

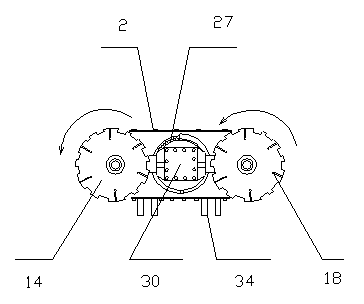

[0020] Such as Figure 1-7 As shown, the present invention provides a cutting blade rotary arm roadheader cutting device, including the following components: cutting head, cutting arm, power transmission system and power device, cutting motor (1), power box (2 ), the telescopic cylinder (32) constitutes the main power device, the telescopic cylinder (32), the cutting motor (1) are fixed on the power box (2), and the power output shaft (3) is installed on the power box (2) In the bearing, the cutting motor (1) is connected with the power take-off shaft (3) of the main power unit. The power input shaft (4) of the cutting head is installed in the bearing on the main body of the cutting arm (5), and the power output shaft (3) of the main power device is the power input shaft of the cutting head with inner pentagon and outer pentagon ( 4) Carry out socketing, the power input shaft gear (25) of the cutting head is fixed on the power input shaft (4) of the cutting head. The cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com