Protective cover mechanism of separation socket

A technology of shedding sockets and protective covers, which is applied in the structural field of aviation missile systems, can solve problems such as limited installation space, complicated implementation methods, and inapplicable structural forms, and achieve the effect of avoiding excessive friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below through specific examples.

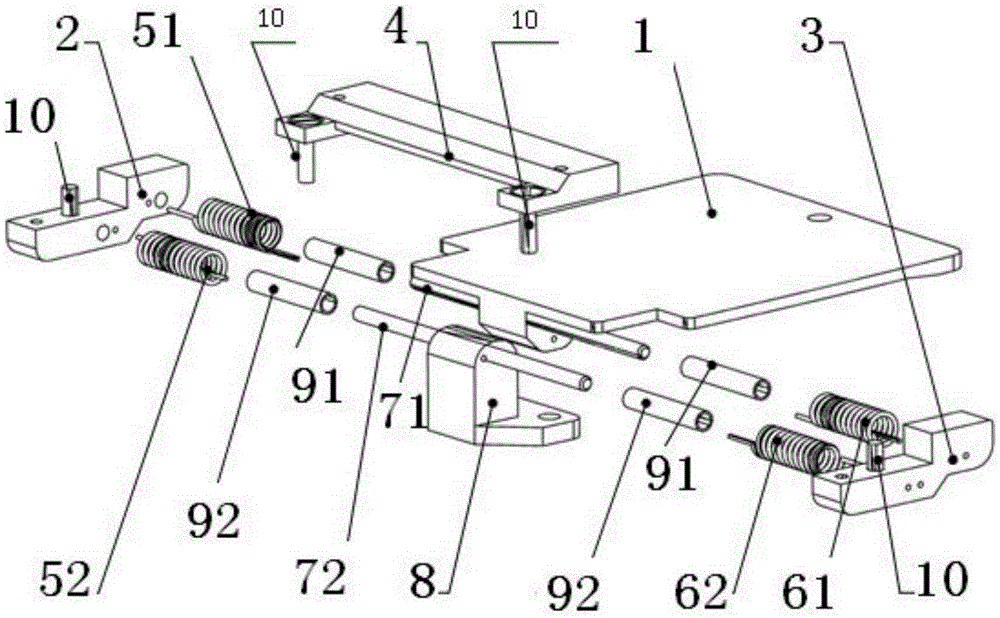

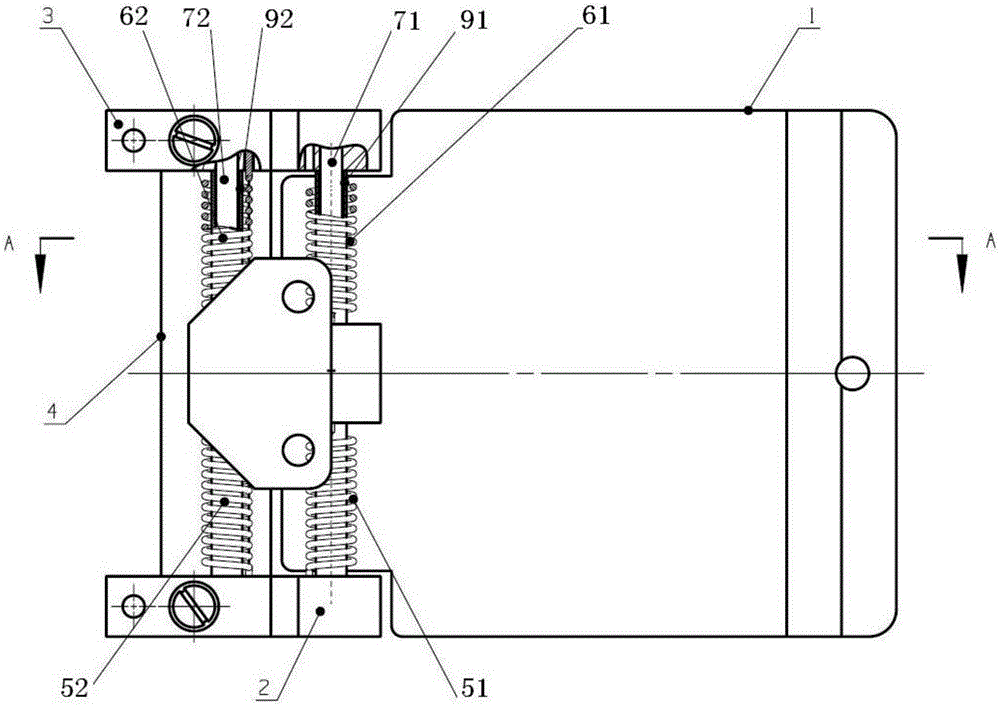

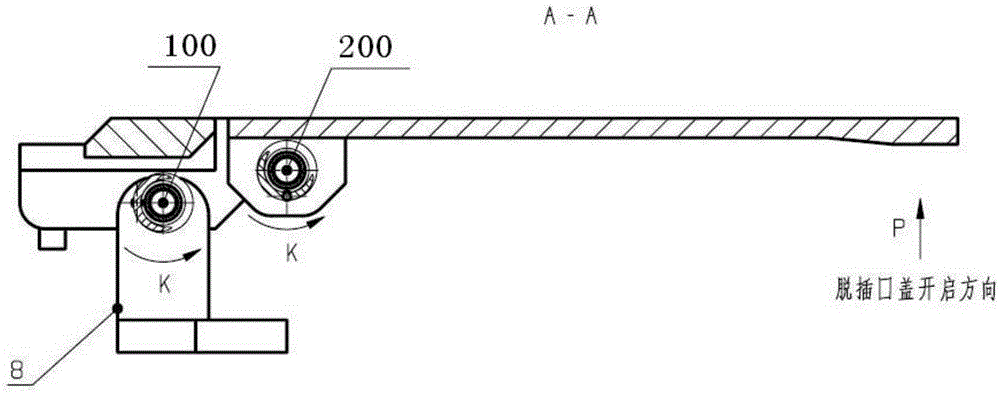

[0036] In this embodiment, the cross-section of a missile projectile body is a square of 230 mm × 190 mm, a shedding socket protective cover mechanism, after the missile is launched and separated, the shedding plug on the launch carrier is separated from the shedding socket on the projectile body, and the The fall-off socket protection cover mechanism automatically rebounds to protect the fall-off socket; the fall-off socket protection cover mechanism is fixed on the body through two mounting holes with a diameter of 2.8 mm on the bracket 8; it also includes a first-stage torsion spring group 100 And the second stage torsion spring group 200; specifically as figure 1 and figure 2 shown;

[0037] 1. The first stage torsion spring group 100

[0038] The first-stage torsion spring group 100 consists of the socket cover 1, the first-stage torsion sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com