Depositing device

A technology of deposition device and fixing device, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems of easily containing impurities and low film quality, and achieve the effect of improving surface quality and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

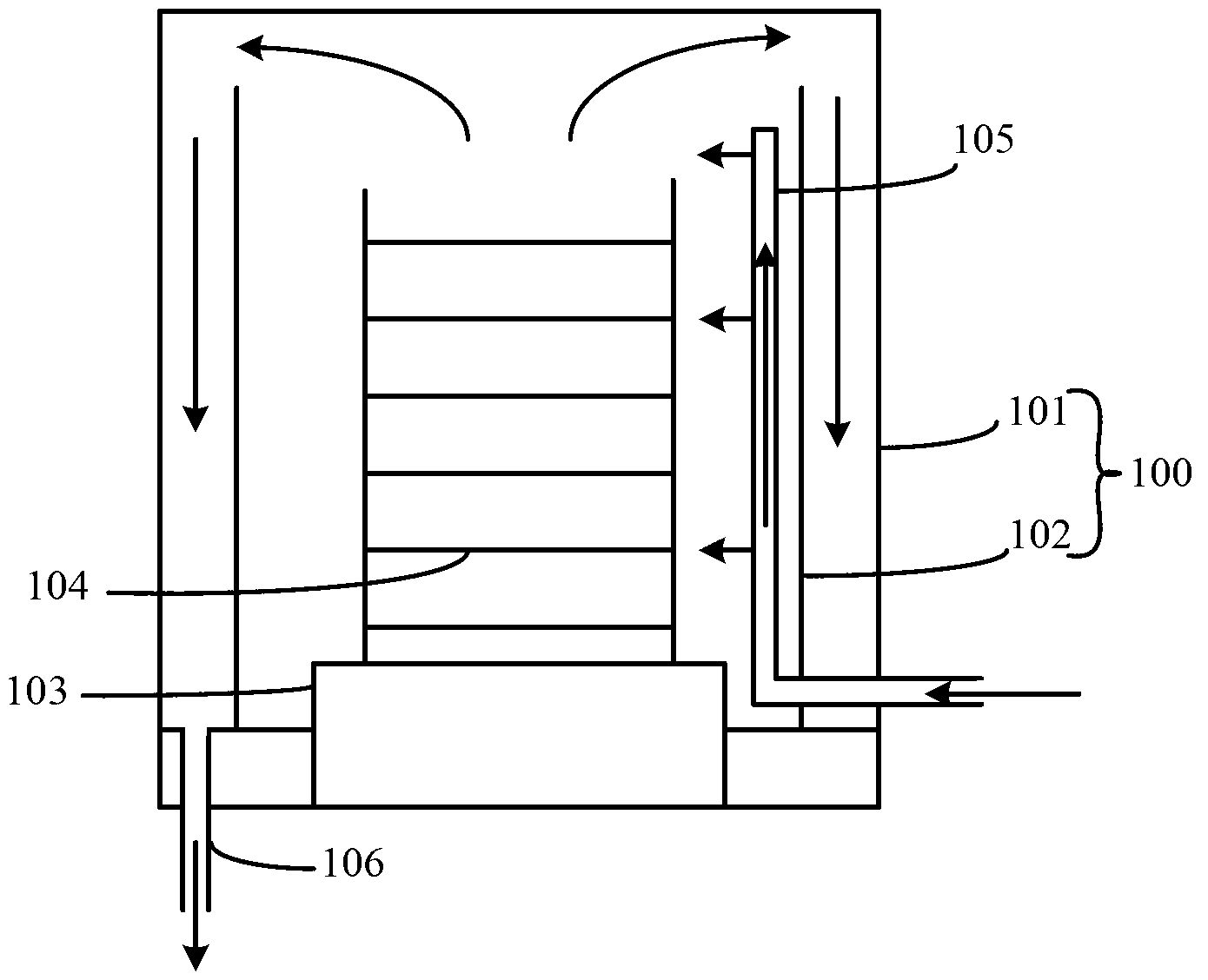

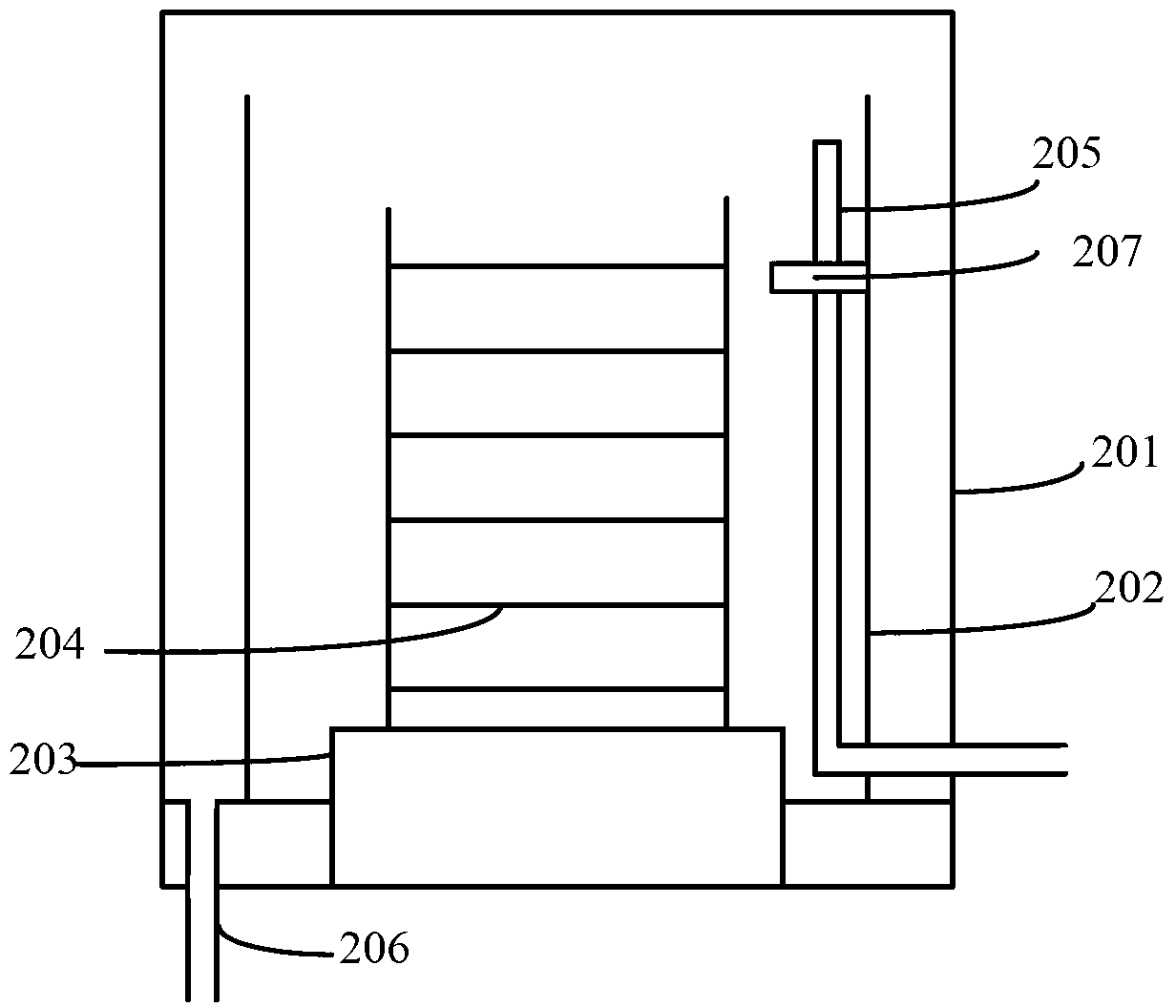

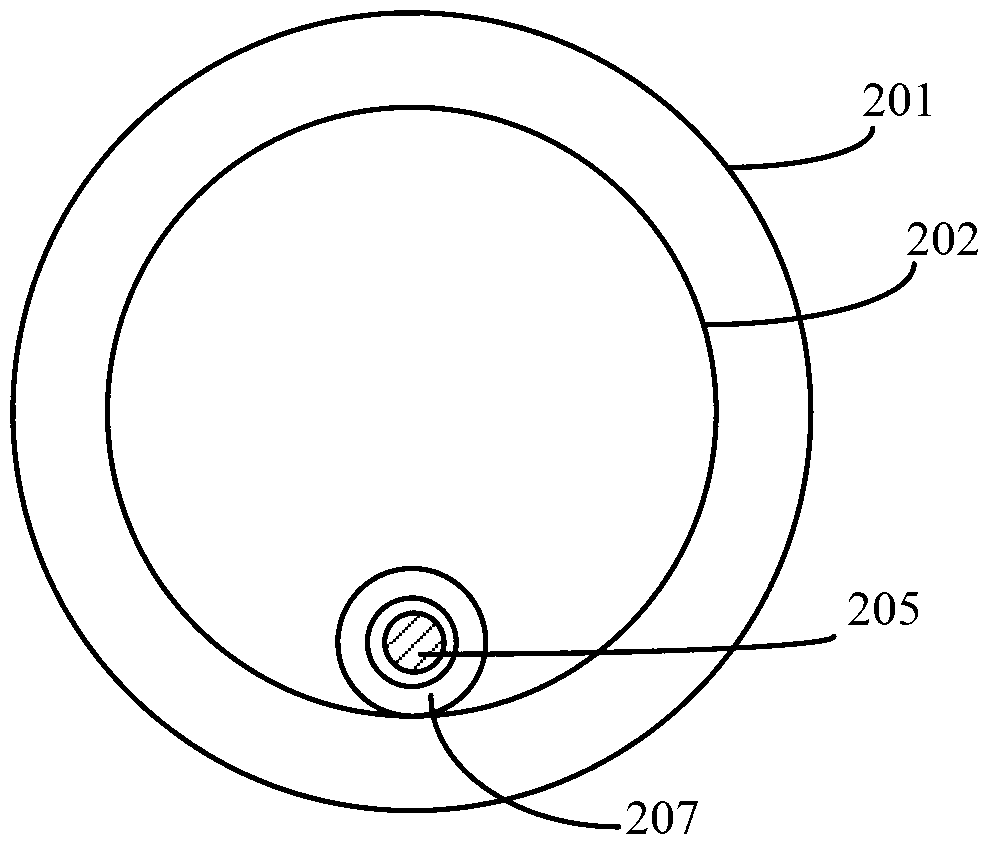

[0034] Please refer to figure 2 , figure 2 It is a schematic cross-sectional structure diagram of the deposition device described in the first embodiment of the present invention, including: an outer furnace tube 201; an inner furnace tube 202 located inside the outer furnace tube 201, the bottom of the inner furnace tube 202 is fixed to the outer furnace tube The bottom of the furnace tube 201, the top of the inner furnace tube 202 is open, and the top of the inner furnace tube 202 is not in contact with the top of the outer furnace tube 201; the base located at the inner bottom of the inner furnace tube 202 203; several overlapping crystal boats 204 fixed on the surface of the base 203; a gas supply pipeline 205 extending from the outside of the outer furnace tube 201 into the interior of the inner furnace tube 202, and the gas supply pipeline 205 is routed from the inner furnace tube 202 The bottom of the furnace tube 202 extends toward the top of the inner furnace tube ...

no. 2 example

[0051] Please refer to Figure 4 with Figure 5 , Figure 4 is a schematic cross-sectional structure diagram of the deposition device described in the second embodiment of the present invention, Figure 5 It is a top view structural diagram of the deposition device described in the second embodiment of the present invention, including: a closed outer furnace tube 301; an inner furnace tube 302 located inside the outer furnace tube 301, the bottom of the inner furnace tube 302 is fixed on the The bottom of the outer furnace tube 301, the top of the inner furnace tube 302 is an opening, and the top of the inner furnace tube 302 is not in contact with the top of the outer furnace tube 301; A base 303; a plurality of overlapping crystal boats 304 fixed on the surface of the base 303; a gas supply pipeline 305 extending from the outside of the outer furnace tube 301 into the interior of the inner furnace tube 302, and the gas supply pipeline 305 is from the The bottom of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com