Double side coating device

A coating device and double-sided technology, applied to the surface coating liquid device, coating, electrode collector coating, etc., to achieve the effect of equipment miniaturization and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

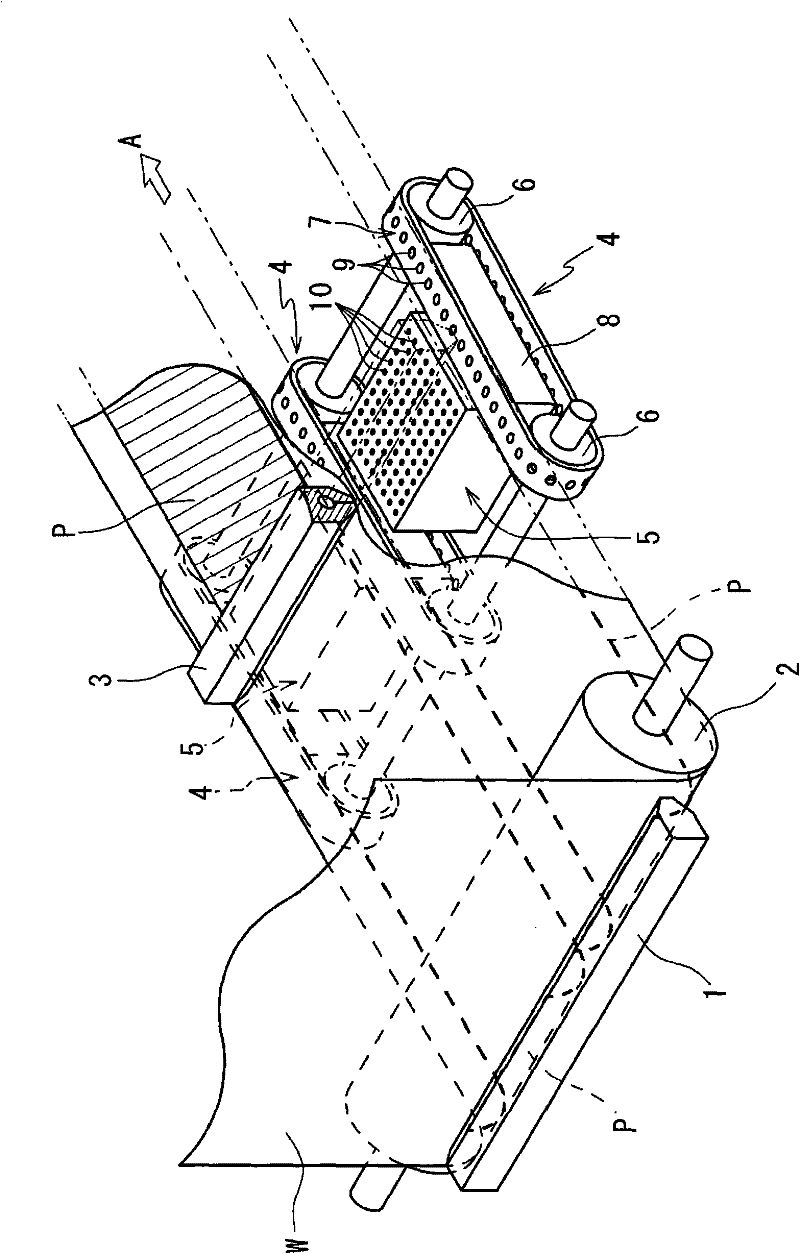

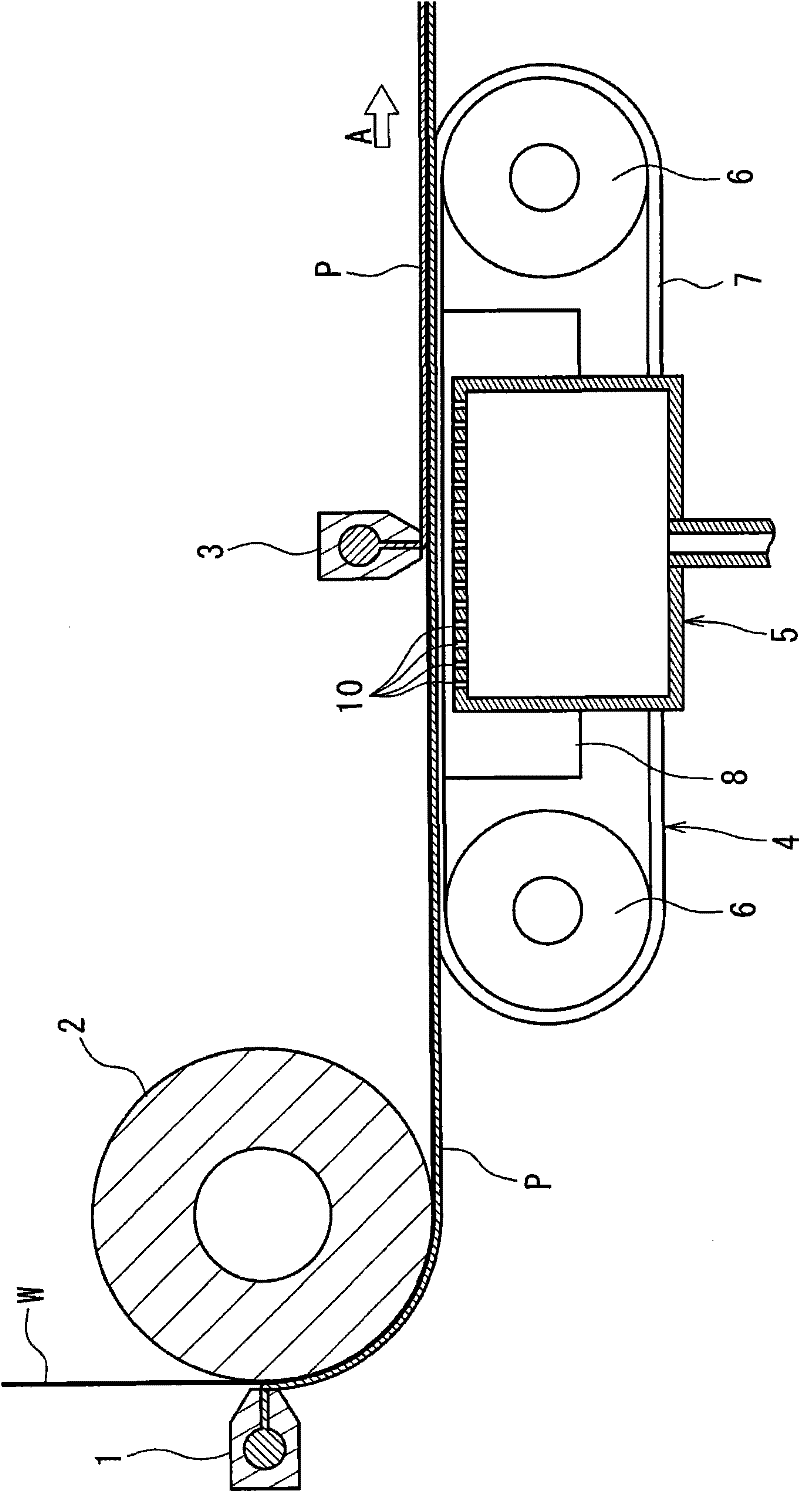

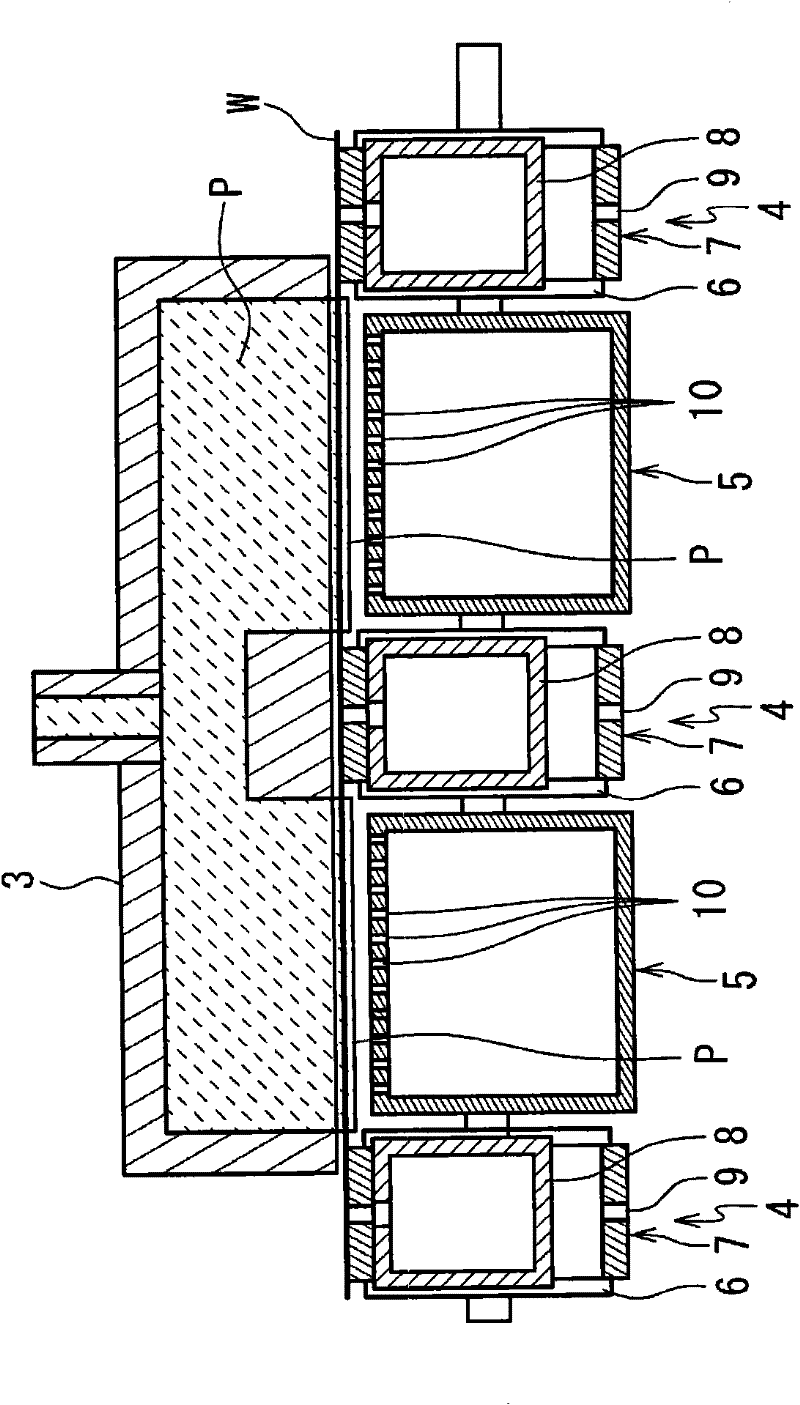

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 1 to Figure 3 The structure of the coating part of the double-sided coating apparatus which concerns on 1st Embodiment of this invention is shown. The double-sided coating device of this embodiment conveys the web material W in the arrow A direction. In addition, the double-sided coating device has: a first finishing head (coating die) 1 that applies the paint P as two lines on the first side (back side) of the fabric material W shape; supporting roller 2, which supports the second surface of the fabric material W at a position opposite to the first coating head 1; the second coating head (coating die head) 3, the second coating head 3 At a position downstream of the conveying direction A of the fabric material W relative to the first finishing head 1, the paint P is applied on the second surface (surface) of the fabric material W so as to be consistent with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com