Shuttle-type high-temperature and high-pressure welding check valve

A high-temperature, high-pressure, check valve technology, applied in valve details, control valves, valve devices, etc., can solve problems such as installation at any angle, leakage of special media, limited applicable environment, etc., and achieve simple structure, small opening and closing resistance, The effect of ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

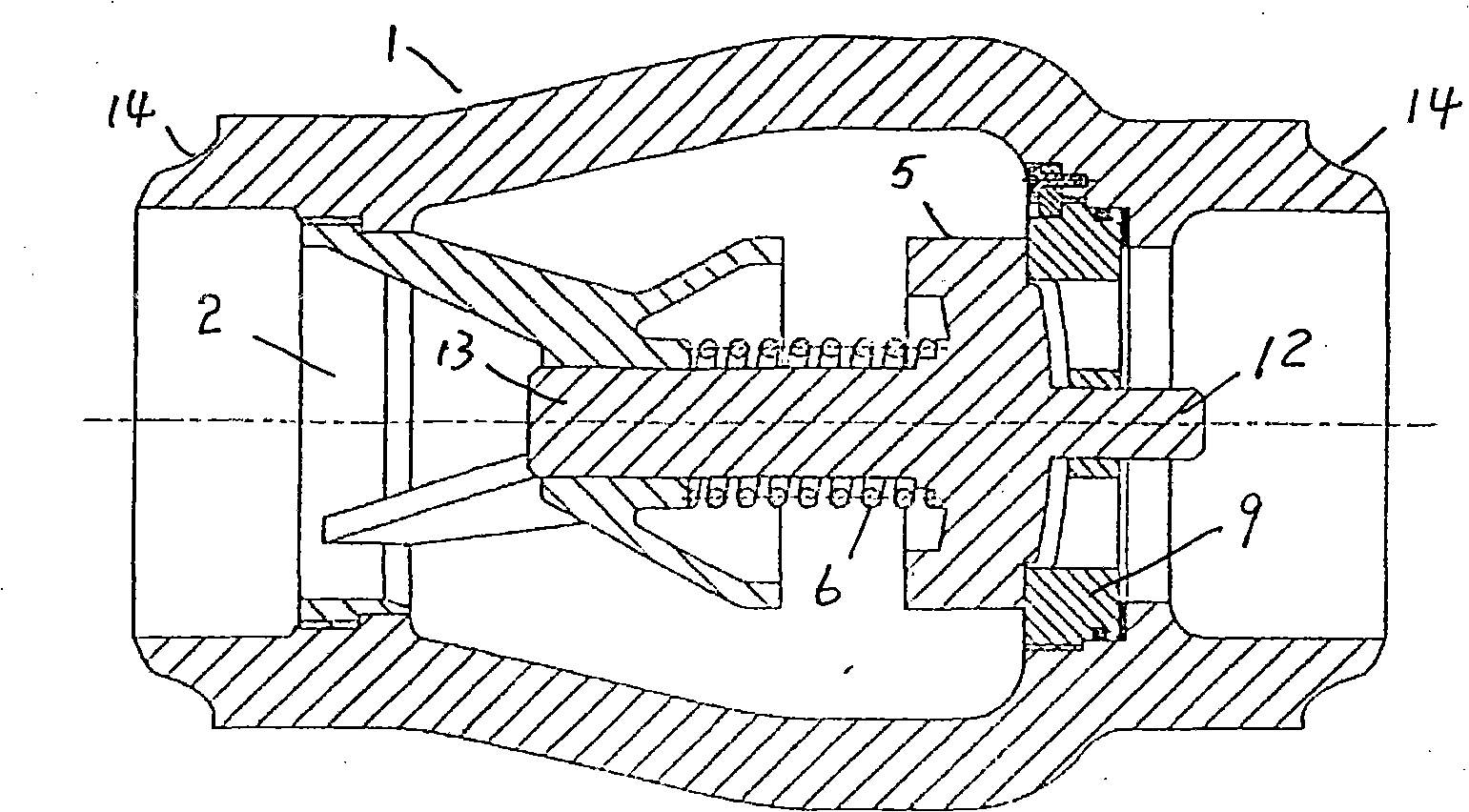

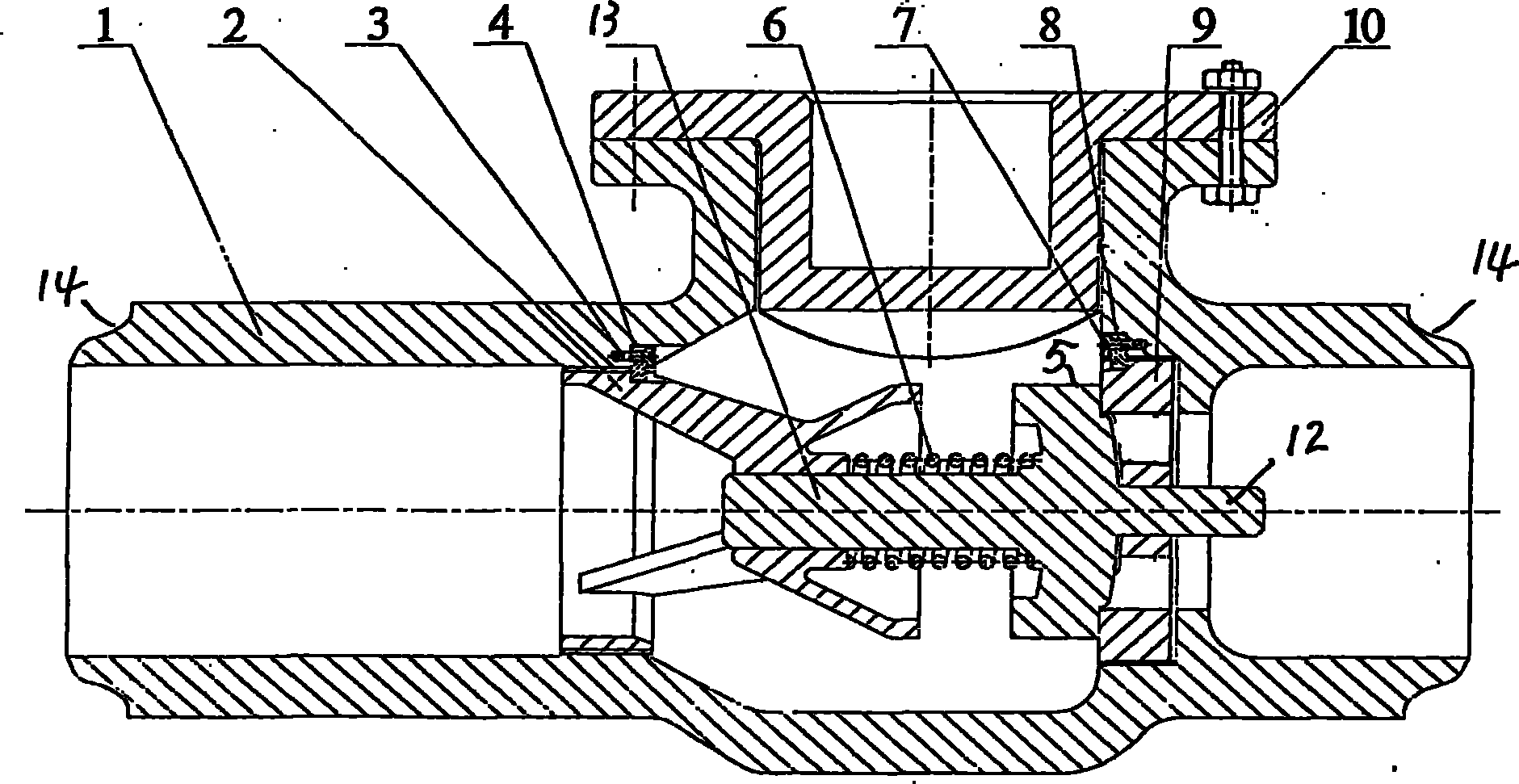

[0021] The middle cavity of the valve body 1 is connected to the joints at both ends in the axial direction, and the outer wall of the port of the joint has welding grooves 14 . The inner wall of the left end joint is threadedly connected with the outer wall of the largest diameter of the valve sleeve 2, and the valve sleeve travels to the right until the end of the left end joint is blocked by a step and stops in place; there is an inner step at the connection between the right end joint and the middle cavity, and the front support 9 is a valve seat , support integrated parts, the front support 9 is installed in the hole on the left side of the inner step, the ring of the front support 9 is the valve seat, the small hole supported by the ribs of the front support 9 is the axial center hole of the front support, and the upstream fluid passes through the ribs Space circulation between strips. The annulus outer diameter of front bearing 9 is less than left end connector step int...

Embodiment 2

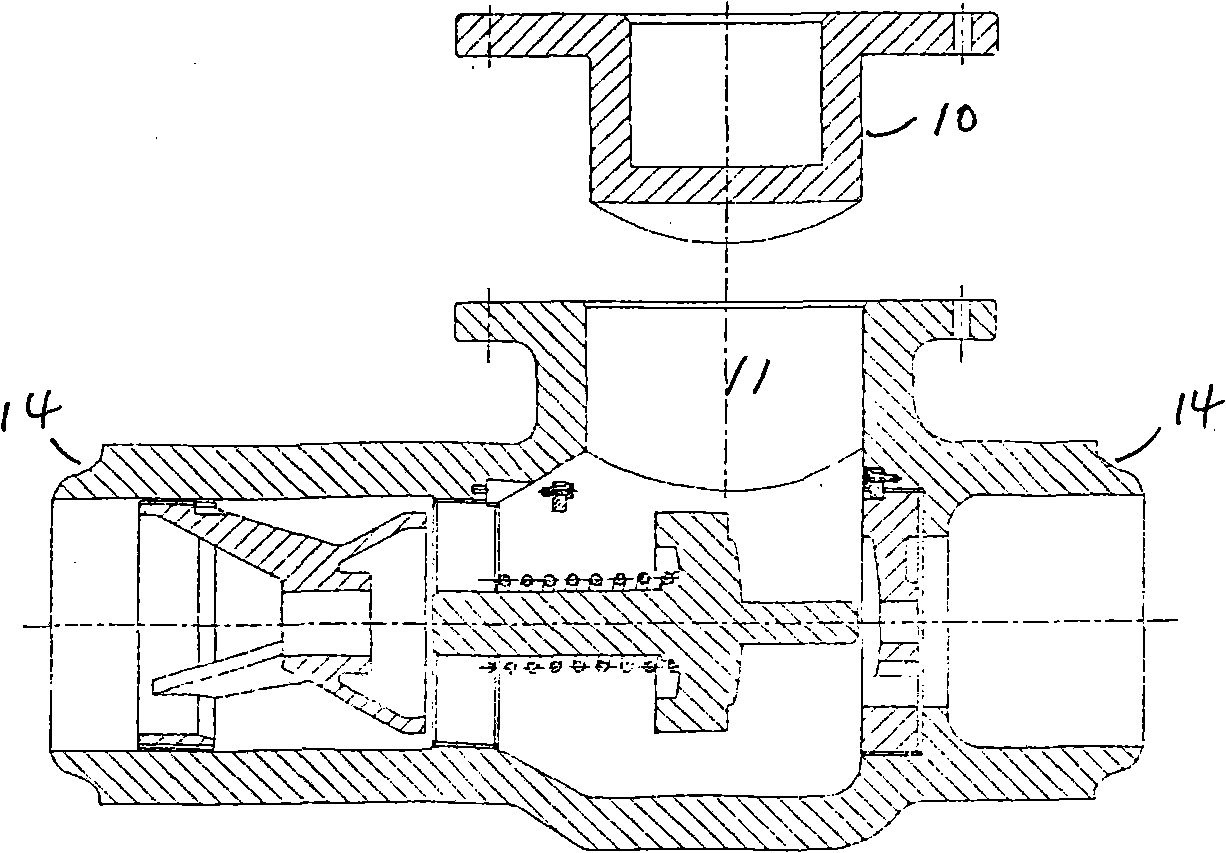

[0023] The middle cavity of the valve body 1 has an inspection hole 11 and the hole cover 10 is connected by flanges and bolts. The axial ends of the middle cavity have left-end threads, right-end steps, left-end threads and the maximum diameter of valve sleeve 2.

[0024] Diameter outer wall threaded connection. The valve sleeve 2 is fixed on the left wall of the middle cavity through a locking pressure piece 4 and a locking screw (or pin) 3 . Front bearing 9 is positioned at the wall hole on the left side of the right end step and is connected with it, and is fixed on the right wall of the middle cavity by locking briquetting block 7 and locking screw (or pin) 8. All the other structures are the same as in Example 1.

[0025] The disassembly process steps of the present invention are as follows:

[0026] a), Disassembly process:

[0027] 1. Take out the inspection hole cover 10: remove the valve sleeve locking screw (or pin) 3 and the valve sleeve locking pressure block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com