Chemical raw material transporting trolley walking lifting mechanism

A technology for handling trolleys and chemical raw materials, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of waste of raw materials, troubles, low efficiency, etc., and achieve the effect of reducing vibration and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

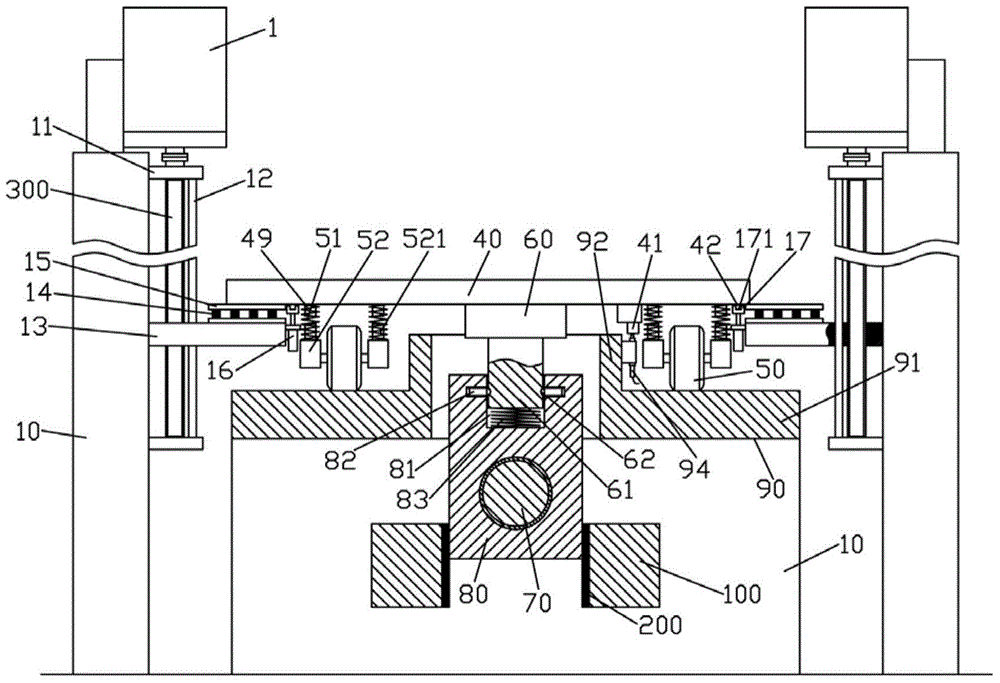

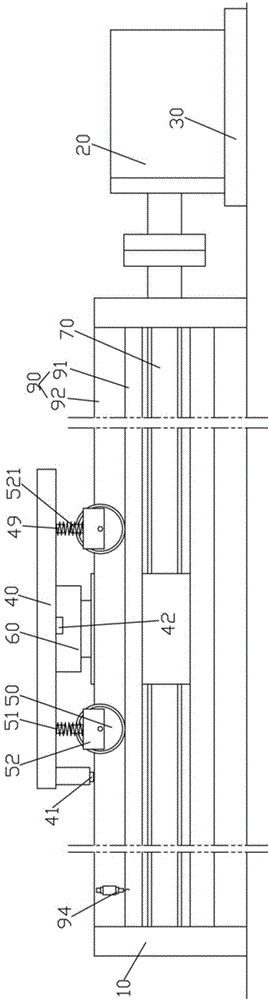

[0019] Examples, see e.g. Figures 1 to 2 As shown, a walking lifting mechanism for a chemical raw material handling trolley includes a base plate 40, the bottom surface of the base plate 40 is provided with a plurality of walking wheels 50, and the middle part of the bottom surface of the base plate 40 is fixed with a mobile connection block 60. The mobile connection block 60 The middle part of the bottom surface has an insertion part 61, and the insertion part 61 is inserted and sleeved in the insertion hole 81 provided on the walking block 80 screwed on the rotating screw rod 70 below the base plate 40, and the inner side wall of the insertion hole 81 is screwed. A connecting ball plunger 82 is connected, and the steel ball of the connecting ball plunger 82 protrudes from the inner side wall of the insertion hole 81 and is nested in the insertion concave hole 62 provided on the outer wall of the insertion portion 61, and the screw rod 70 is rotated. The two ends are hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com