Constant force grinding and polishing head mechanism

A technology of polishing head and constant force, which is applied in the direction of grinding/polishing equipment, parts of grinding machine tools, grinding machines, etc. It can solve problems such as low efficiency, rising defective products, and damaged grinding tools, so as to avoid damage and improve processing Accuracy and efficiency, and the effect of reducing idle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but do not constitute a limitation of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

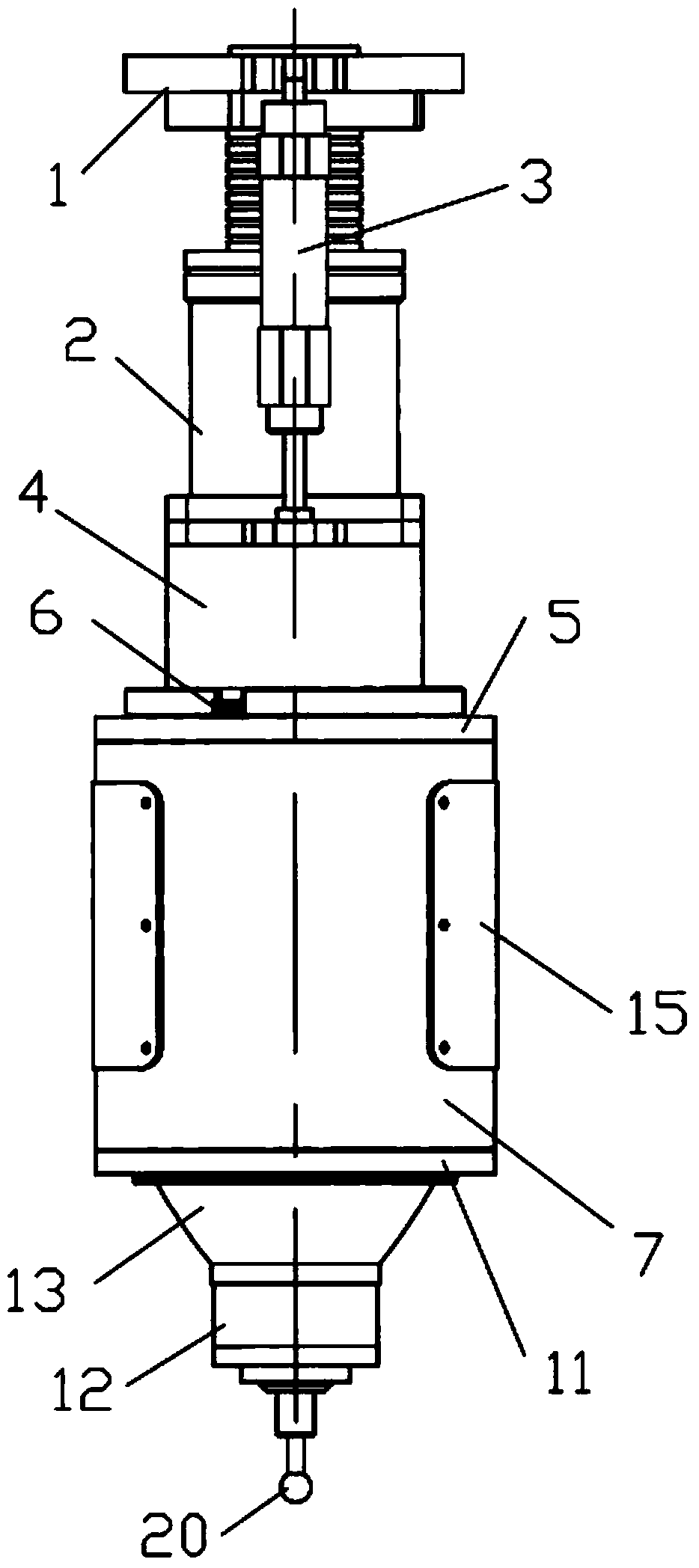

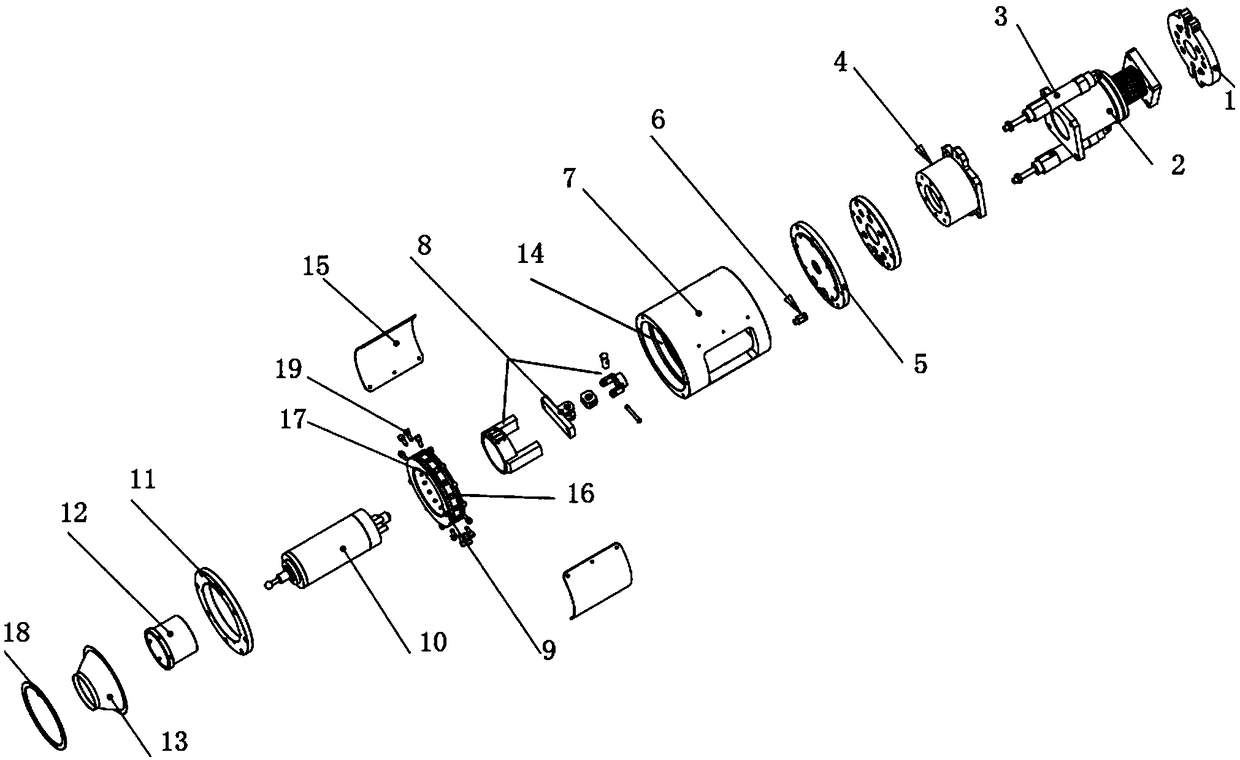

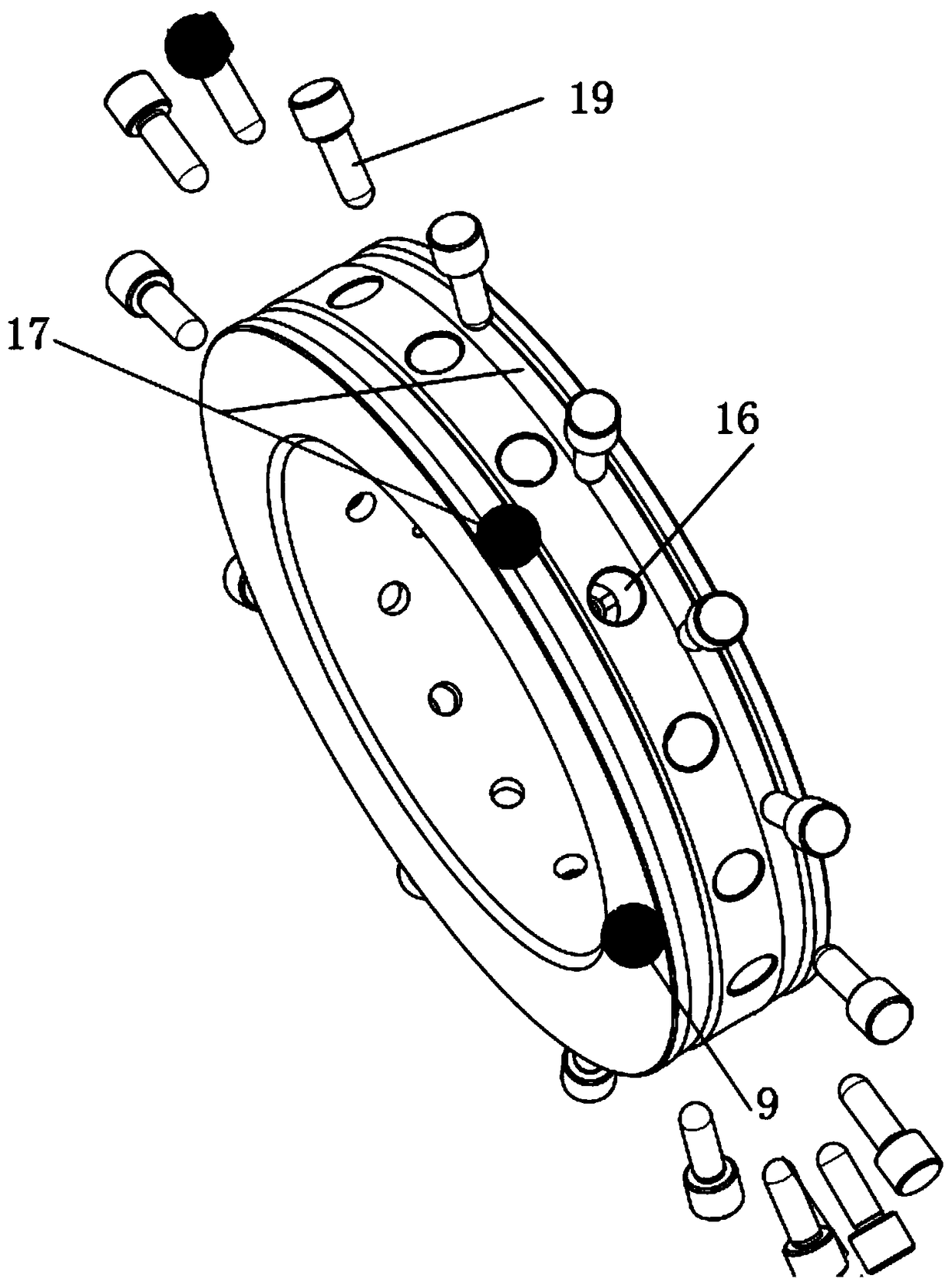

[0040] like Figure 1-Figure 3 As shown in the figure, a constant force grinding and polishing head mechanism includes a robot connecting flange 1, a linear motor 2, a balanced low-friction cylinder 3, a motor flange seat 4, a top connecting flange 5, an air source connecting head 6, a casing 7, Universal joint assembly 8, radial constant force floating air ring 9, spindle motor 10, front fixing flange 11, shaft sleeve 12, conical protective cover 13;

[0041] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com