Intercooler pipeline fixing structure

A fixed structure, cooler technology, applied in machine/engine, combustion engine, non-rotational vibration suppression, etc., can solve problems such as large swinging body, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

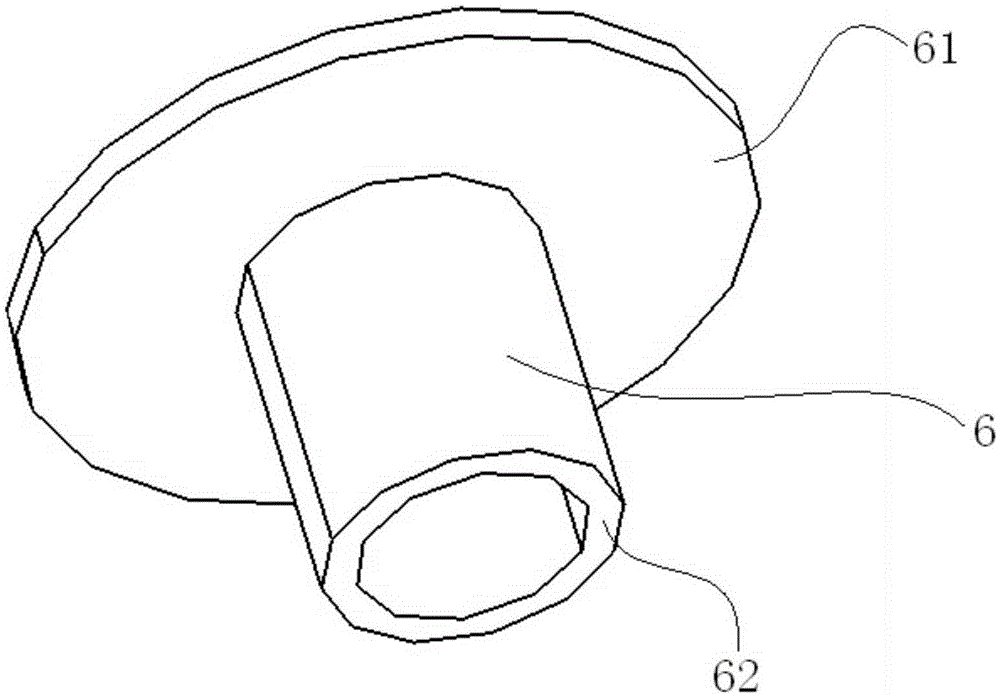

[0025] refer to figure 2 , The top end of the steel sleeve 6 used in this embodiment has a flange 61 .

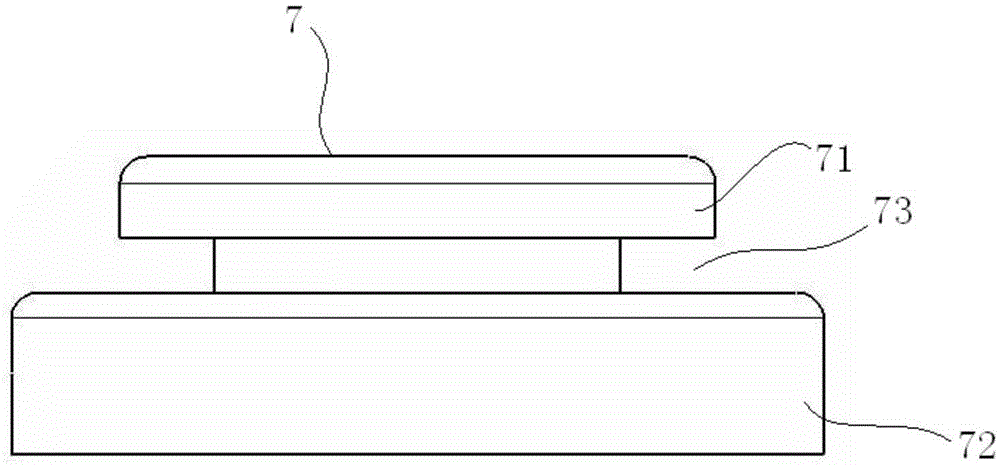

[0026] refer to image 3 , Figure 4 with Figure 5 , The cushion 7 used in this embodiment has an upper flange 71 , a lower flange 72 and a first annular groove 73 between the upper flange 71 and the lower flange 72 . The opening of the first ring groove 73 is located at the side of the cushion 7 . from Figure 4 and Figure 5 It can be seen more clearly that the lower flange 72 has a plurality of concentric second annular grooves 74 with openings located on the bottom surface of the cushion 7,

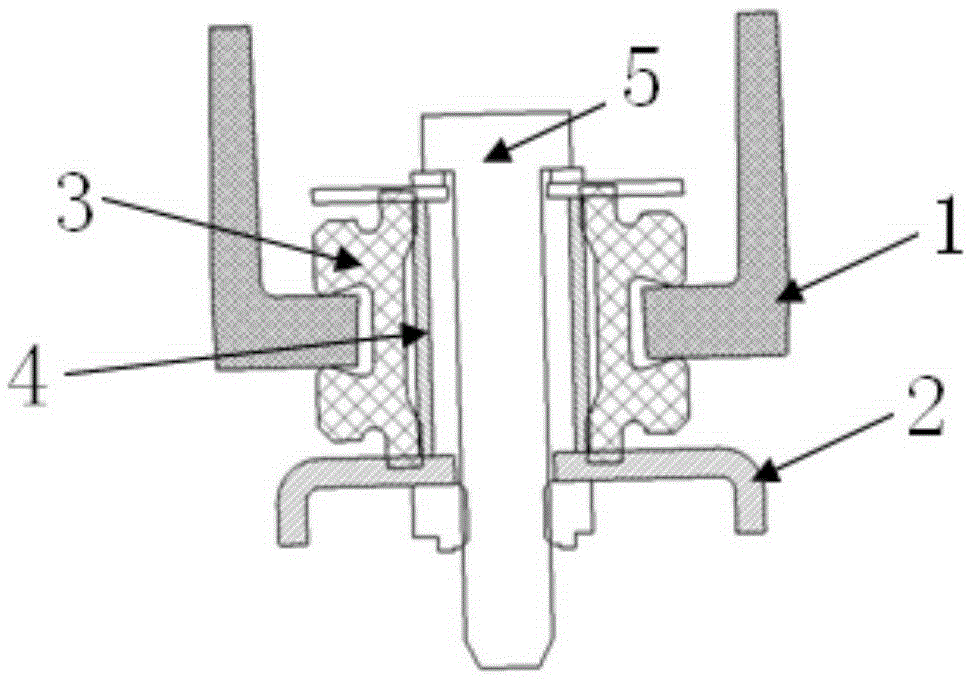

[0027] refer to Image 6 with Figure 7 , the intercooler pipeline fixing structure in this embodiment includes: an intercooler pipeline bracket 1 for fixing the intercooler pipeline, an engine fixing bracket 2 for supporting the intercooler pipeline on the engine, Bolt 5, steel sleeve 6 and cushion 7. The height of the soft pad 7 is greater than the height of the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com