Light emitting device and package assembly for light emitting device

A technology for light-emitting devices and assemblies, applied in the fields of packaging assemblies for light-emitting devices, light-emitting devices, and conductive connecting parts, can solve problems such as adverse effects of light-emitting diodes, and achieve the effects of strong vibration resistance and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

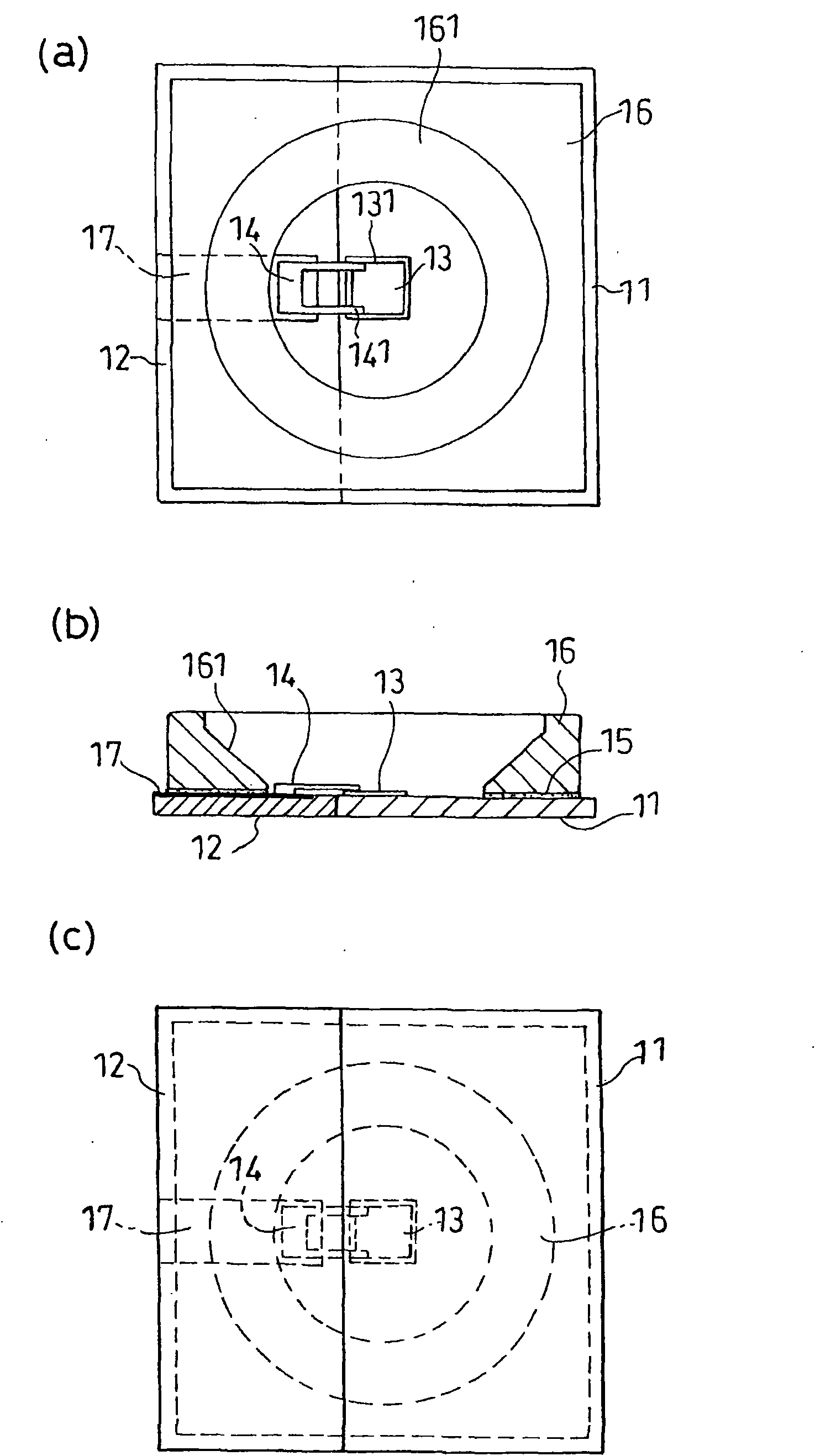

[0049] figure 1 (a)~(c) are embodiment 1 of the present invention, figure 1 (a) is a plan view of the light emitting device, figure 1 (b) is a cross-sectional view of the light emitting device, figure 1 (c) is a bottom view of the light emitting device. In the drawings of the present invention, in order to make the description easier to understand, the magnitude relationship does not necessarily match the actual one. exist figure 1 In (a) to (c), the metal substrate 11 and the ceramic substrate 12 are constituted by a single substrate that is in contact with each other. The reflective frame 16 straddles the metal substrate 11 and the ceramic substrate 12, and integrally fixes the bottom with, for example, a thermosetting resin adhesive.

[0050] The metal substrate 11 is made of, for example, aluminum, copper, iron, or alloys thereof, and is surface-treated with nickel and silver as necessary. The lower electrodes (not shown) of the upper and lower electrode type li...

Embodiment 2

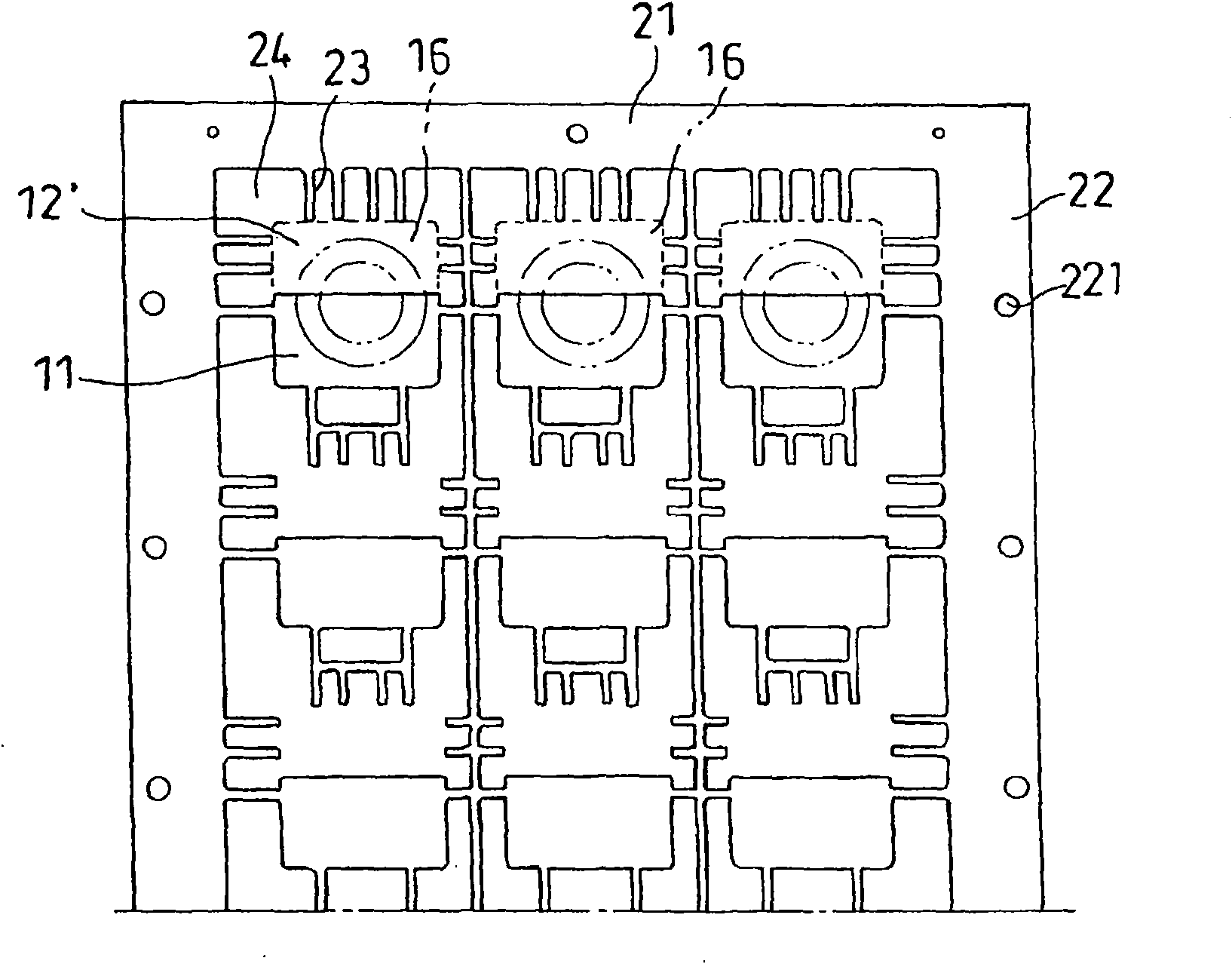

[0058] figure 2 It is a figure for explaining the lead frame provided with the several light emitting diode package connection body. figure 2In the lead frame 21, a plurality of groups of a pair of metal substrates 11 and ceramic substrate fitting holes 12' are connected to the above frame 22 and other metal substrates by using a plurality of lead connection parts 23 composed of weak parts in the frame 22. The substrate 11 or the above-mentioned ceramic substrate fitting holes 12' are connected to form a package connection body. In addition, a plurality of space portions 24 surround the metal substrate 11 and the ceramic substrate fitting hole 12'. The above-mentioned space portion 24 is provided with at least one lead wire connecting portion 23, which is connected to the above-mentioned frame 22, other metal substrate 11 or ceramic substrate fitting hole 12'. In addition, the metal substrate 11 and the ceramic substrate fitting holes 12' may be provided on the frame 22 (l...

Embodiment 3

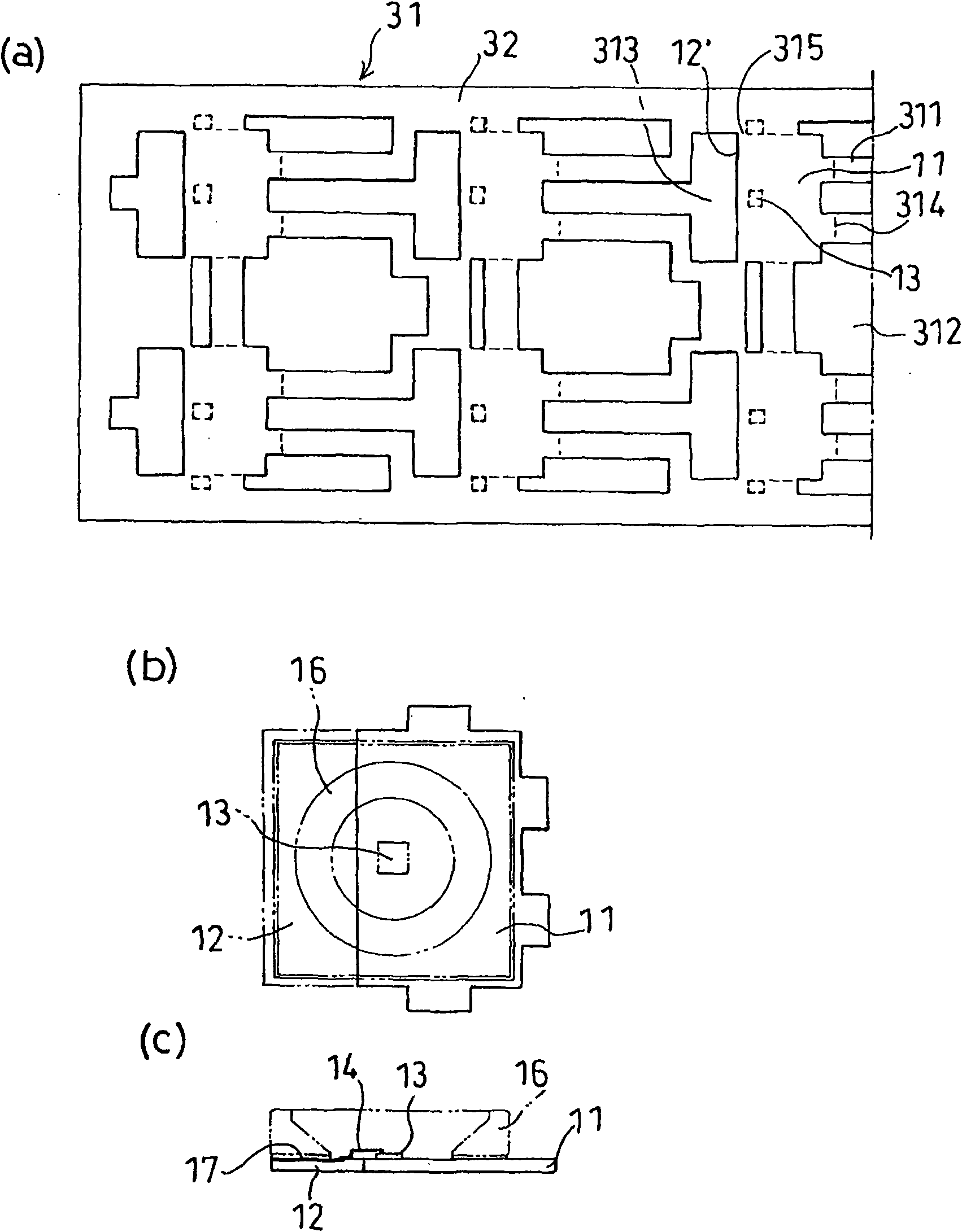

[0061] image 3 (a)-(c) are figures for demonstrating the state where the lead frame provided with the several light emitting diode package connection body, and the upper-lower electrode type light emitting diode were mounted. image 3 In (a), the lead frame 31 is that a plurality of sets of a pair of metal substrates 11 and ceramic substrate fitting holes 12' are connected to the above-mentioned frame 32 and other metal substrates by using a plurality of lead connection parts 311 in the frame 32. 11 or above ceramic substrate fitting hole 12'. In addition, the metal substrate 11 and the ceramic substrate fitting hole 12' are surrounded by a plurality of space portions 312. The above-mentioned space portion 312 is provided with at least one lead wire connecting portion 311, which is connected to the above-mentioned frame 32, other metal substrates 11 or ceramic substrate fitting holes 12'. In addition, the metal substrate 11 and the ceramic substrate fitting holes 12' may be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com