Electromagnetic wave shielding film, shielded printed wiring board, and electronic device

A technology for printed circuit boards and electronic equipment, applied in the fields of magnetic/electric field shielding, circuit devices, printed circuit components, etc., can solve the problems of interlayer tight bonding damage and poor shielding characteristics, and achieve high shielding characteristics, The effect of reducing the space and making the adhesion between layers difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, the electromagnetic wave shielding film of this invention is demonstrated concretely. However, the present invention is not limited to the following embodiments, and can be appropriately modified and used without changing the gist of the present invention.

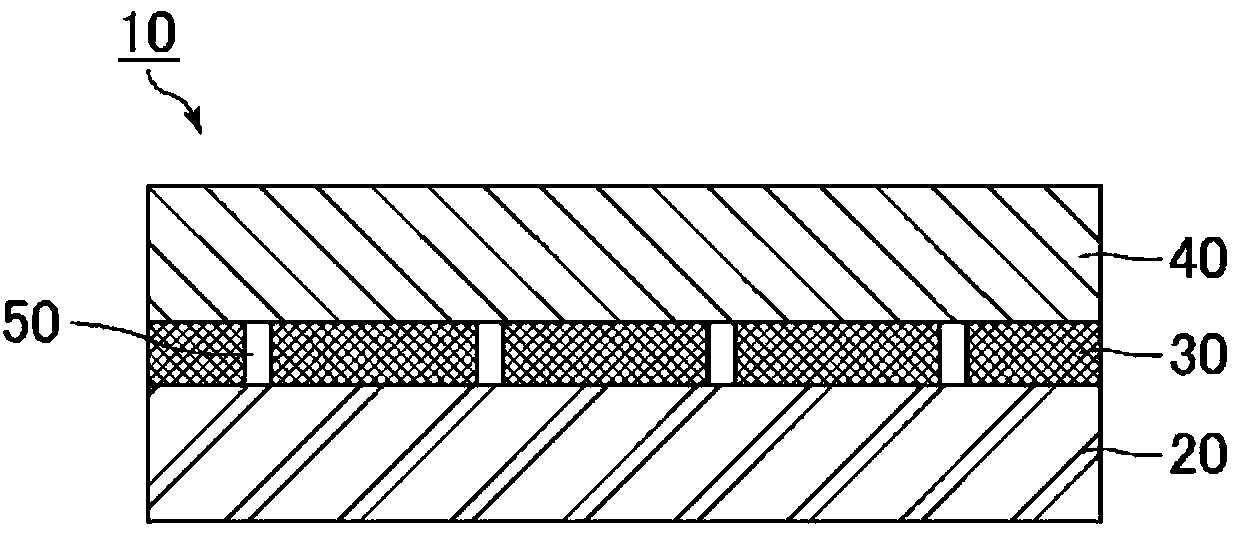

[0085] figure 2 It is a cross-sectional schematic diagram of an example of the electromagnetic wave shielding film of this invention.

[0086] Such as figure 2 As shown, the electromagnetic wave shielding film 10 includes a conductive adhesive layer 20 , a shielding layer 30 laminated on the conductive adhesive layer 20 , and an insulating layer 40 laminated on the shielding layer 30 .

[0087] In addition, a plurality of openings 50 are formed in the shield layer 30 .

[0088] (conductive adhesive layer)

[0089] In the electromagnetic wave shielding film 10 , the conductive adhesive layer 20 only needs to have conductivity and function as an adhesive, and may be made of any material.

[0090] F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com