Efficient nano-infrared energy-saving low-temperature hot stick

A low-temperature heat and nanotechnology, applied in the field of hot rods, can solve the problems of inability to supply heat, frost heave of roadbed, etc., and achieve the effect of good sealing performance, special structural design, and easy disassembly, replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

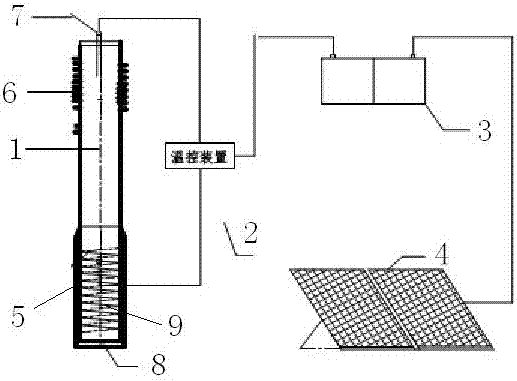

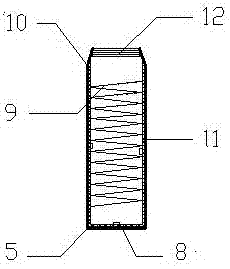

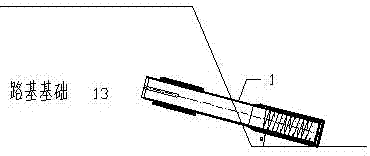

[0023] Such as Figure 1-3 shown.

[0024] A high-efficiency nano-infrared energy-saving low-temperature heating rod, one end of the heating rod 1 located outside the soil body is equipped with a heating outer tube 5 ( image 3 ), the molecular vibration dark infrared heating wire 9 of nano-alloy material is arranged in a longitudinal helical manner in the heating outer tube 5; a plurality of thermal sensors 8 are installed in the heating outer tube 5, and a central temperature measuring tube 7 is also arranged in the center of the heating rod, and the heating The sensitive sensor 8 is connected with the central temperature measuring tube 7 and the temperature control device 2; the electric energy of the molecular vibration dark infrared heating wire 9 of nano-alloy material is provided by the solar power generation panel 4, and the electric energy is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com