Gravure printing method and gravure printing article

A technology of gravure printing and printing roller, which is applied in the field of gravure printing method and gravure printing, which can solve the problems of FM net without density fluctuation, increase of process, and use restrictions, and achieve the effect of high-precision gravure printing and avoid ripples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

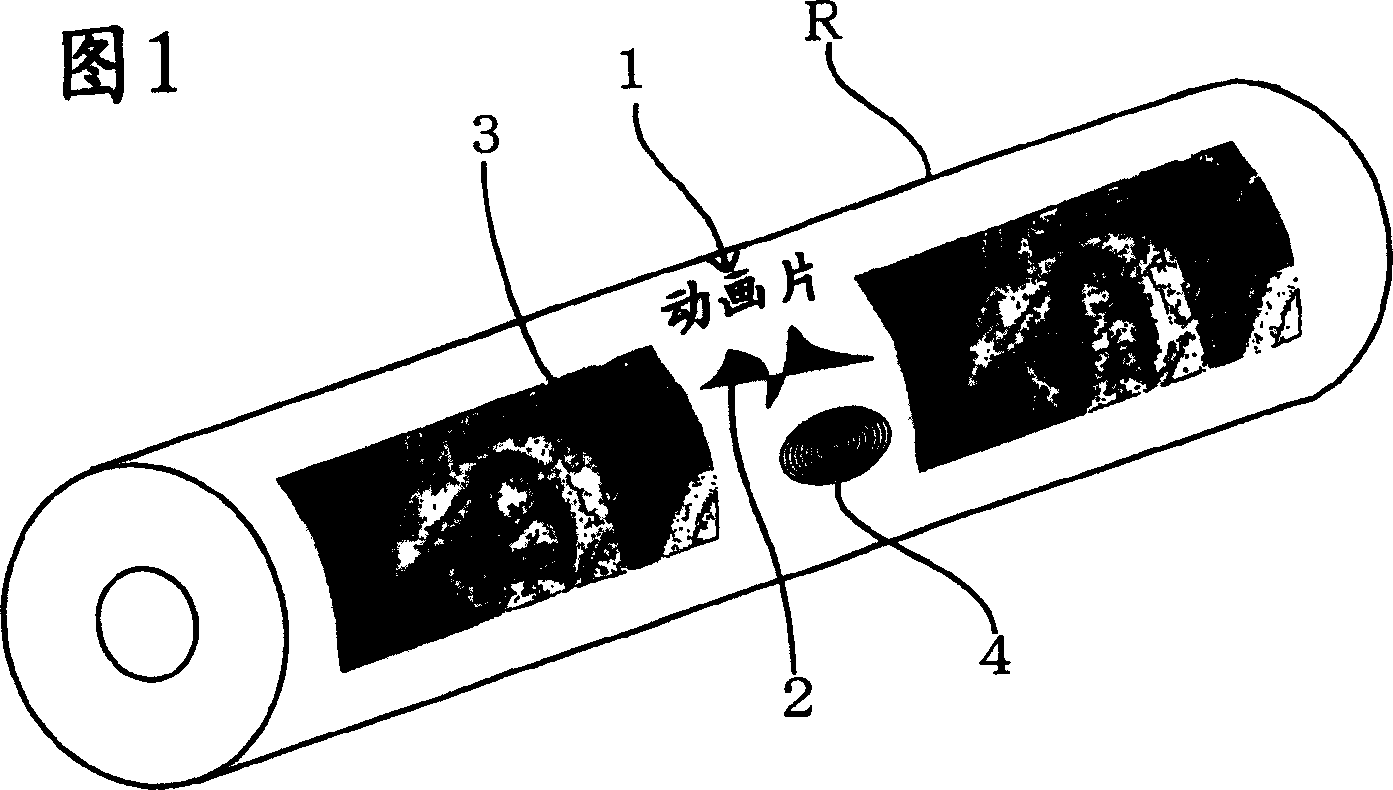

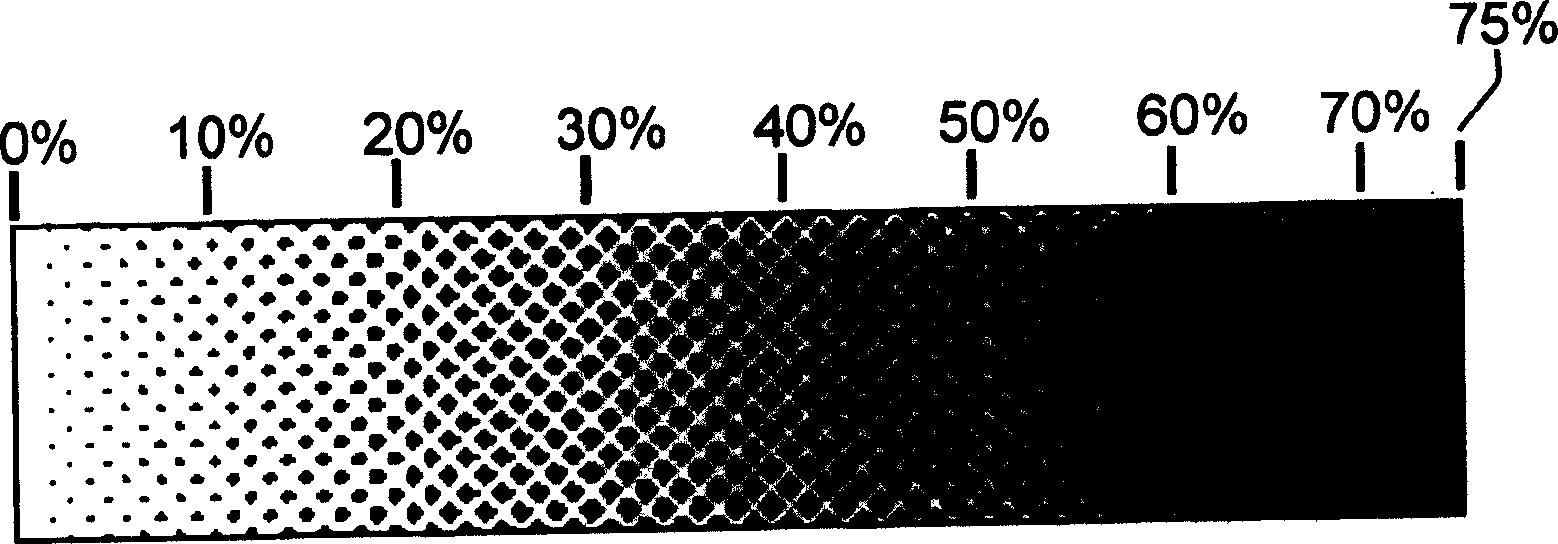

[0042] As shown in Figure 1, with respect to one roller R, for the corresponding meshes that need to form characters 1 and reproduced images 2 with a thick ink concentration, image 3 The AM mesh formation shown; for the mesh of the photographic image 3 and the thin line 4 expressed in shades, the Figure 4 The FM network formation shown in C1.

Embodiment 2

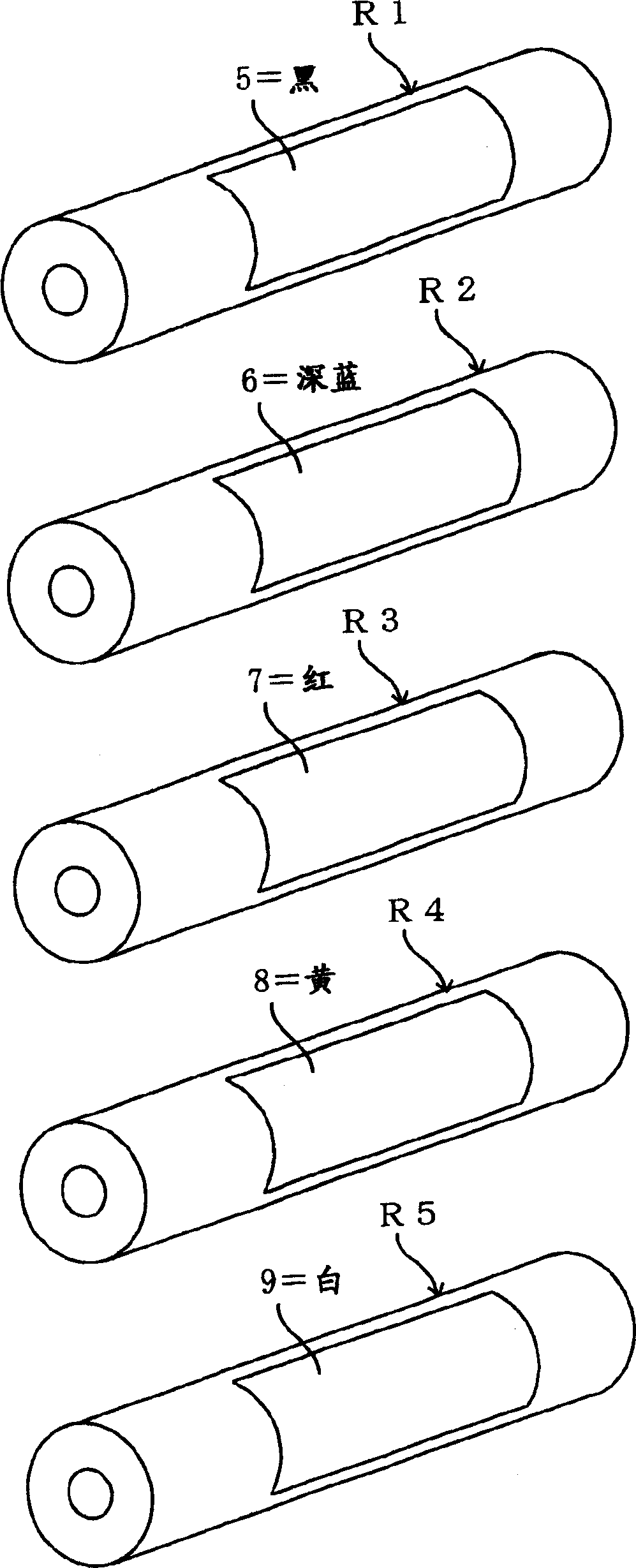

[0044] Such as figure 2 As shown, for example, in the gravure printing method when 5 printing rollers are used to overprint black, blue, red, yellow and white 5 colors of gravure printing, the gravure printing roller R1 is installed in the first printing section to print black, and in the second printing section The gravure printing roll R2 is installed in the printing section to print blue, the gravure printing roll R3 is installed in the third printing section to print red, the gravure printing roll R4 is installed in the fourth printing section to print yellow, and the gravure printing roll is installed in the fifth printing section R5 is printed in white.

[0045] In black and white printing, the mesh structure of the plate image 5 or 9 that forms the gravure printing roll for this printing is due to the image 3 The AM network shown is formed so that thick ink concentrations can be obtained.

[0046] Blue, red and yellow printing, forming the mesh structure of the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com