A kind of pickling anti-corrosion anti-fogging agent and preparation method thereof

A fog suppressant and corrosion inhibitor technology, which is applied in the field of pickling corrosion inhibitor and fog suppressor and its preparation, can solve the problems of unrecoverable plasticity, corrosion of casting matrix, and metal embrittlement, etc., so as to reduce hydrogen embrittlement, reduce corrosion, prevent The effect of pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

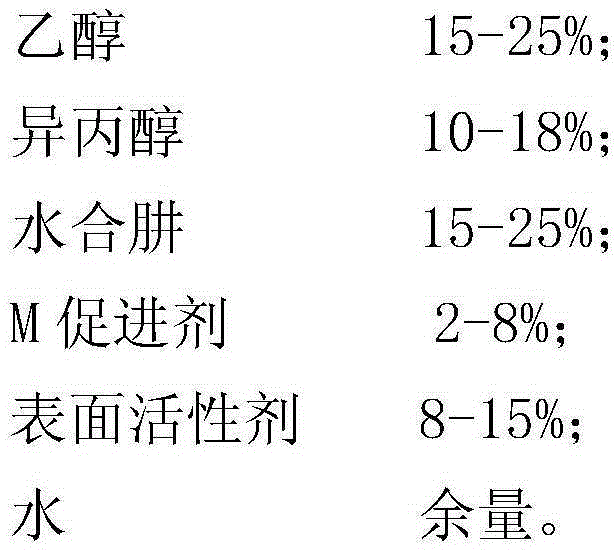

[0022] The anti-corrosion and anti-fogging agent is composed of the following components in proportion (total weight: 100Kg):

[0023] components

ethanol

Isopropanol

Hydrazine hydrate

M Accelerator

Surfactant

water

Weight (Kg)

15

18

25

2

8

32

Weight percentage (%)

15

18

25

2

8

32

[0024] Wherein, the surfactant is a quaternary ammonium salt cationic surfactant.

[0025] The preparation method of above-mentioned anti-corrosion and anti-fogging agent is as follows:

[0026] a. Add the above-mentioned M accelerator, ethanol, and isopropanol into the reaction kettle, and stir for 35 minutes until uniform to obtain solution A;

[0027] b, add above-mentioned water, surfactant to solution A, obtain solution B after stirring;

[0028] c. Add the above-mentioned hydrazine hydrate to the solution B, and stir for 33 minutes to obtain the finished pickling corrosion and fog inhibito...

Embodiment 2

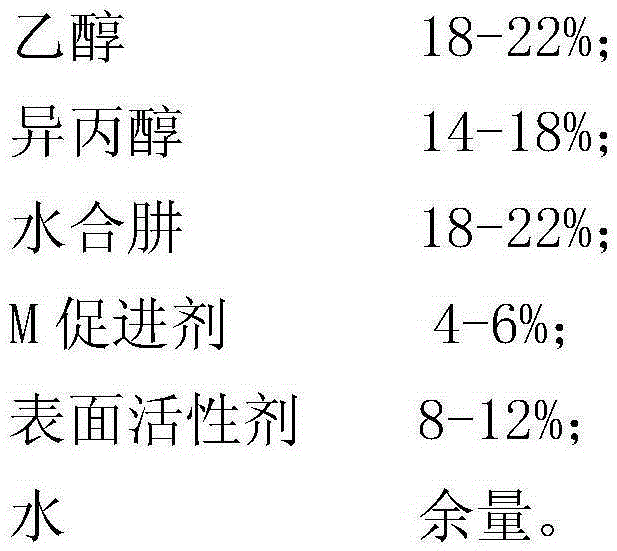

[0034] The anti-corrosion and anti-fogging agent is composed of the following components in proportion (total weight: 100Kg):

[0035] components

ethanol

Isopropanol

Hydrazine hydrate

M Accelerator

Surfactant

water

Weight (Kg)

23

13

16

7

14

27

Weight percentage (%)

23

13

16

7

14

27

[0036] Wherein, the surfactant is polyoxyethylene ether nonionic surfactant.

[0037] The preparation method of above-mentioned anti-corrosion and anti-fogging agent is as follows:

[0038] a. Add the above-mentioned M accelerator, ethanol, and isopropanol into the reaction kettle, and stir for 30 minutes until uniform to obtain solution A;

[0039] b, add above-mentioned water, surfactant to solution A, obtain solution B after stirring;

[0040] c. Add the above-mentioned hydrazine hydrate to the solution B, and stir for 28 minutes to obtain the finished pickling corrosion and fog inhibitor. ...

Embodiment 3

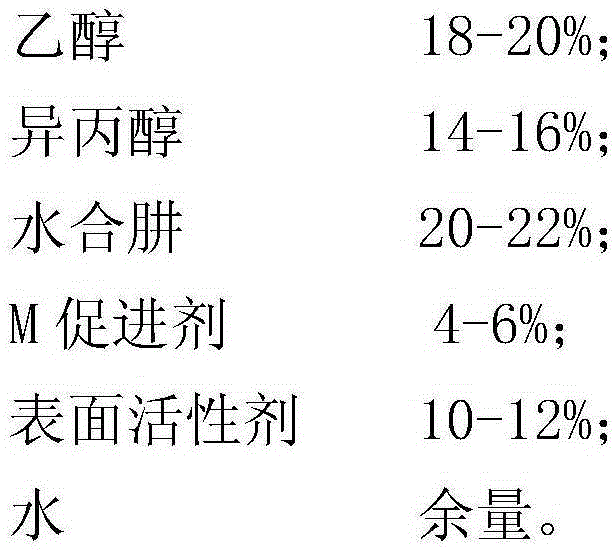

[0046] The anti-corrosion and anti-fogging agent is composed of the following components in proportion (total weight: 100Kg):

[0047] components

ethanol

Isopropanol

Hydrazine hydrate

M Accelerator

Surfactant

water

[0048] Weight (Kg)

25

10

15

8

15

27

Weight percentage (%)

25

10

15

8

15

27

[0049] Wherein, the surfactant is an organic amine surfactant.

[0050] The preparation method of above-mentioned anti-corrosion and anti-fogging agent is as follows:

[0051] a. Add the above-mentioned M accelerator, ethanol, and isopropanol into the reaction kettle, and stir for 25 minutes until uniform to obtain solution A;

[0052] b, add above-mentioned water, surfactant to solution A, obtain solution B after stirring;

[0053] c. Add the above-mentioned hydrazine hydrate to the solution B, and stir for 30 minutes to obtain the finished pickling corrosion and fog inhibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com