Ni-P-PFA-SiO2 nano composite coating and preparation method thereof

A technology of ni-p-pfa-sio2 and ni-p-ptfe-sio2, which is applied in the field of Ni-P-PFA-SiO2 nanocomposite coating and its preparation, can solve the problem of poor wear resistance and insufficient hardness of Ni-P coating , high porosity and other problems, to achieve the effect of reducing porosity, improving corrosion resistance and excellent hardness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

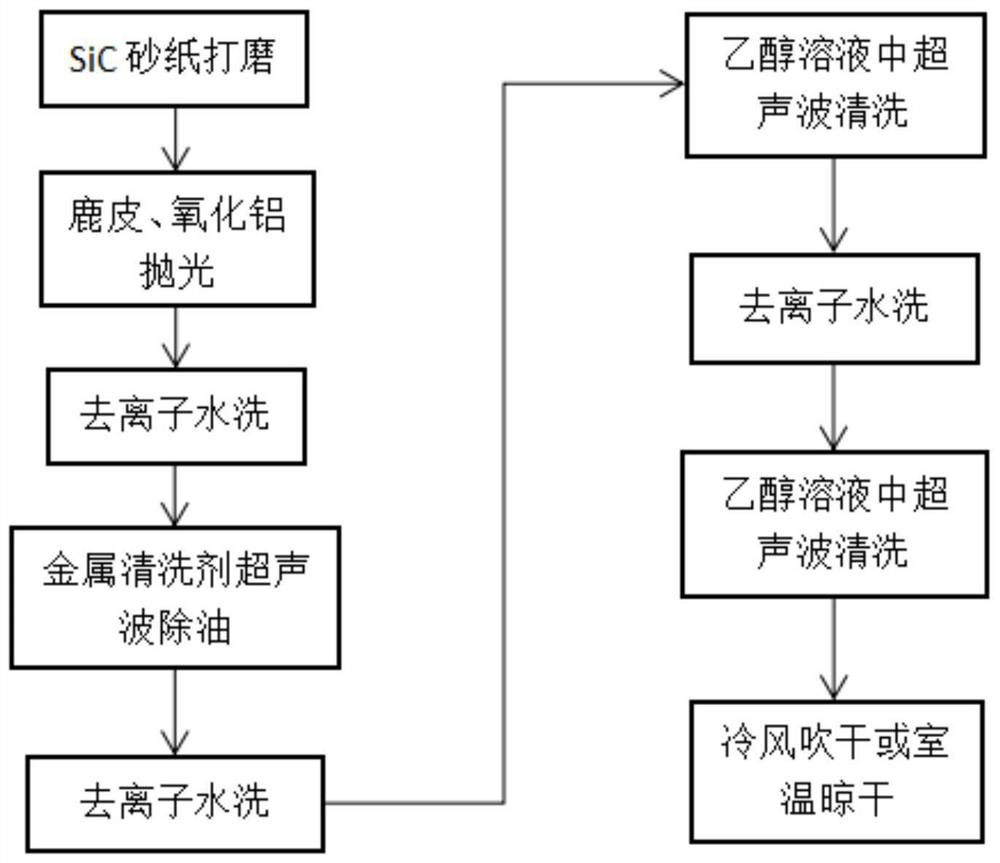

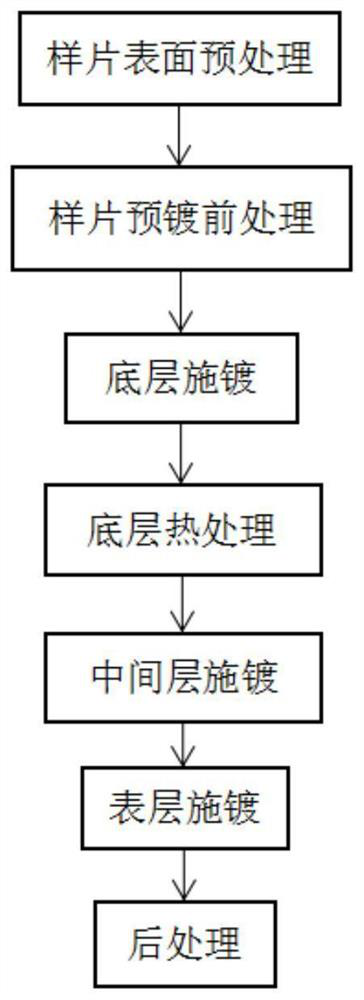

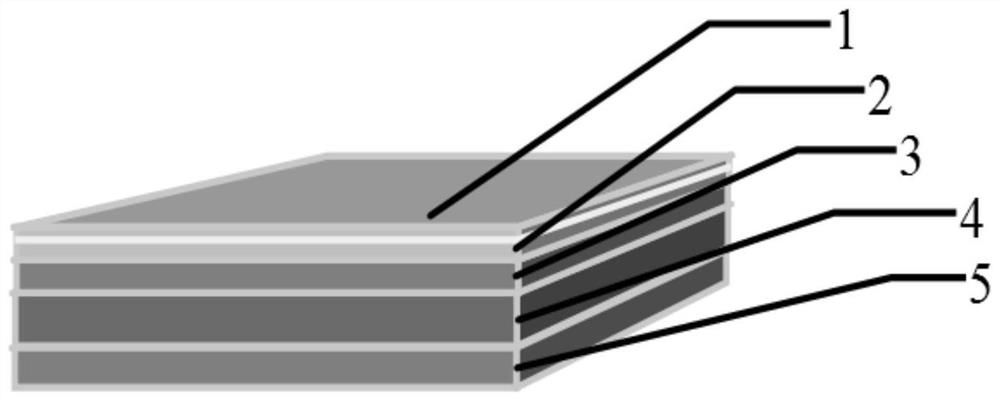

Method used

Image

Examples

Embodiment 1

[0045] Polished steel with NaOH 20g / L, Na 2 CO 3 20g / L, Na 3 PO 4 20g / L, Na 2 SiO 3 The 12g / L mixed lye was washed at 70°C for 10 minutes, rinsed with tap water at 75°C, and then washed with deionized water at 80°C. After that, the steel sample was energized at 4V and 3A for 2 minutes. Perform electric alkaline washing in the same alkaline solution, soak in dilute hydrochloric acid solution for 30s after washing with deionized water, and wash with deionized water to obtain pretreated steel;

[0046] Hang the pretreated steel in the Ni-P layer plating solution (nickel sulfate 30g / L, sodium hypophosphite 30g / L, sodium citrate 15g / L, anhydrous sodium acetate 15g / L, glycine 0.5g / L, pH In 4.5), plating was performed at 90°C for 2 hours, rinsed with 80°C deionized water after the end, dried in a vacuum furnace, and cooled to room temperature (under vacuum conditions during the cooling process); then hung on Ni- P-SiO 2 Layer plating solution (nickel sulfate 30g / L, sodium h...

Embodiment 2

[0049] Polished steel with NaOH 30g / L, Na 2 CO 3 30g / L, Na 3 PO 4 40g / L, Na 2 SiO 3 The 5g / L mixed lye was washed at 65°C for 10 minutes, rinsed with tap water at 70°C, and then washed with deionized water at 90°C. After that, the steel sample was energized at 5V and 5A for 4 minutes. Perform electric alkaline washing in the same alkaline solution, soak in dilute hydrochloric acid solution for 30s after washing with deionized water, and wash with deionized water to obtain pretreated steel;

[0050] Hang the pretreated steel in the Ni-P layer plating solution (nickel sulfate 20g / L, sodium hypophosphite 30g / L, sodium citrate 20g / L, anhydrous sodium acetate 20g / L, glycine 0.5g / L, pH 5.0), plating at 90°C for 2h, rinsed with 80°C deionized water after the end, dried in a vacuum furnace, and cooled to room temperature (under vacuum conditions during the cooling process); then hung on Ni- P-SiO 2 Layer plating solution (nickel sulfate 20g / L, sodium hypophosphite 30g / L, sod...

Embodiment 3

[0053] Polished steel with NaOH 25g / L, Na 2 CO 3 30g / L, Na 3 PO 4 30g / L, Na 2 SiO 3 Alkali solution mixed with 5g / L was washed at 60°C for 7 minutes, rinsed with tap water at 70°C, and then washed with deionized water at 80°C, and then the steel sample was energized at 8V and 3A for 2 minutes. Conduct electric alkaline washing in the same alkaline solution, soak in dilute hydrochloric acid solution for 20s after washing with deionized water, and wash with deionized water to obtain pretreated steel;

[0054] Hang the pretreated steel in the Ni-P layer plating solution (nickel sulfate 20g / L, sodium hypophosphite 25g / L, sodium citrate 20g / L, anhydrous sodium acetate 20g / L, glycine 0.5g / L, pH In 4.6), apply plating at 80°C for 1 hour, rinse with 80°C deionized water after completion, dry in a vacuum furnace, and cool to room temperature (under vacuum conditions during cooling); then hang on Ni- P-SiO 2 Layer plating solution (nickel sulfate 20g / L, sodium hypophosphite 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com