Ink printing grooving machine with punching device

A slotting machine and ink technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of wasting manpower and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

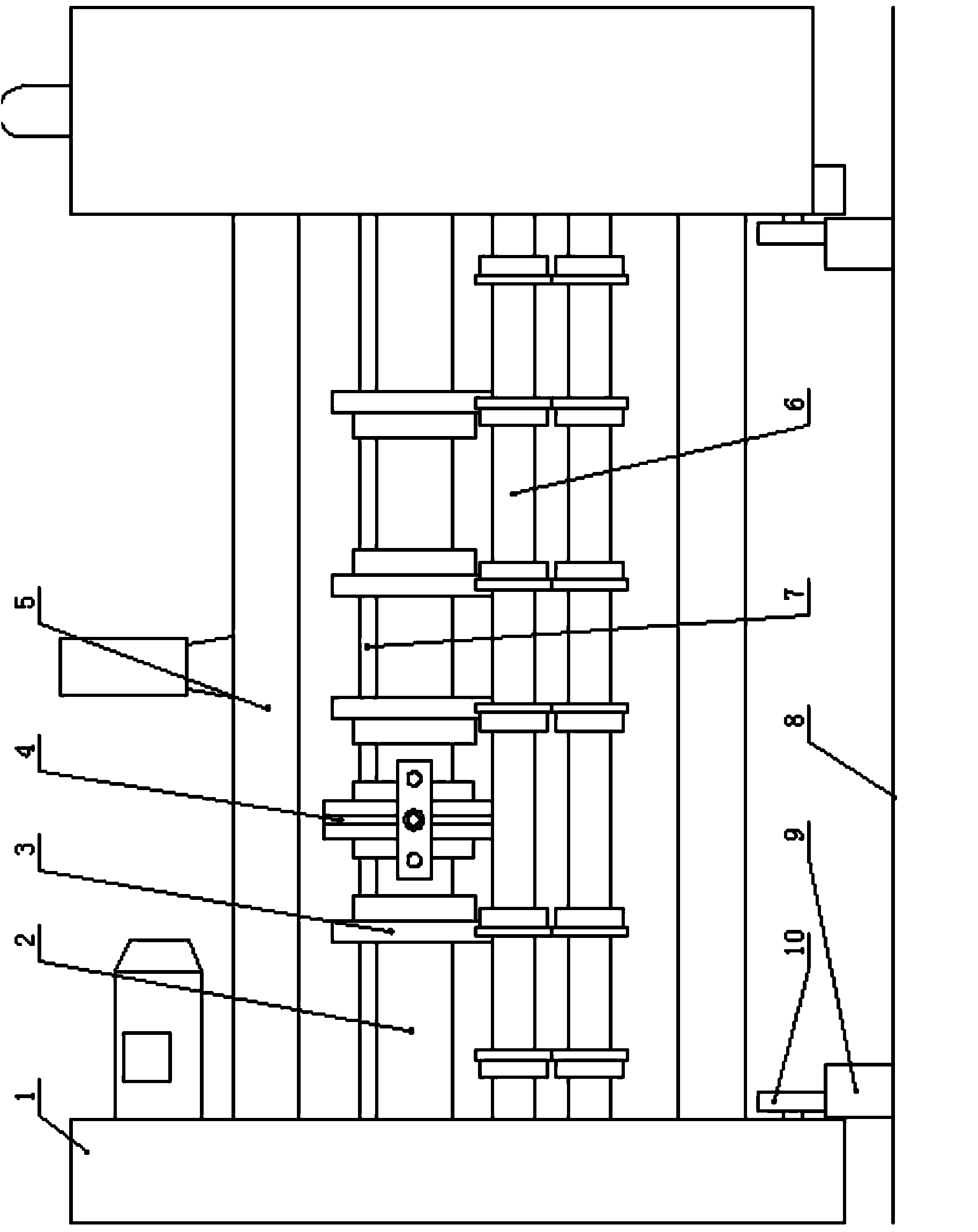

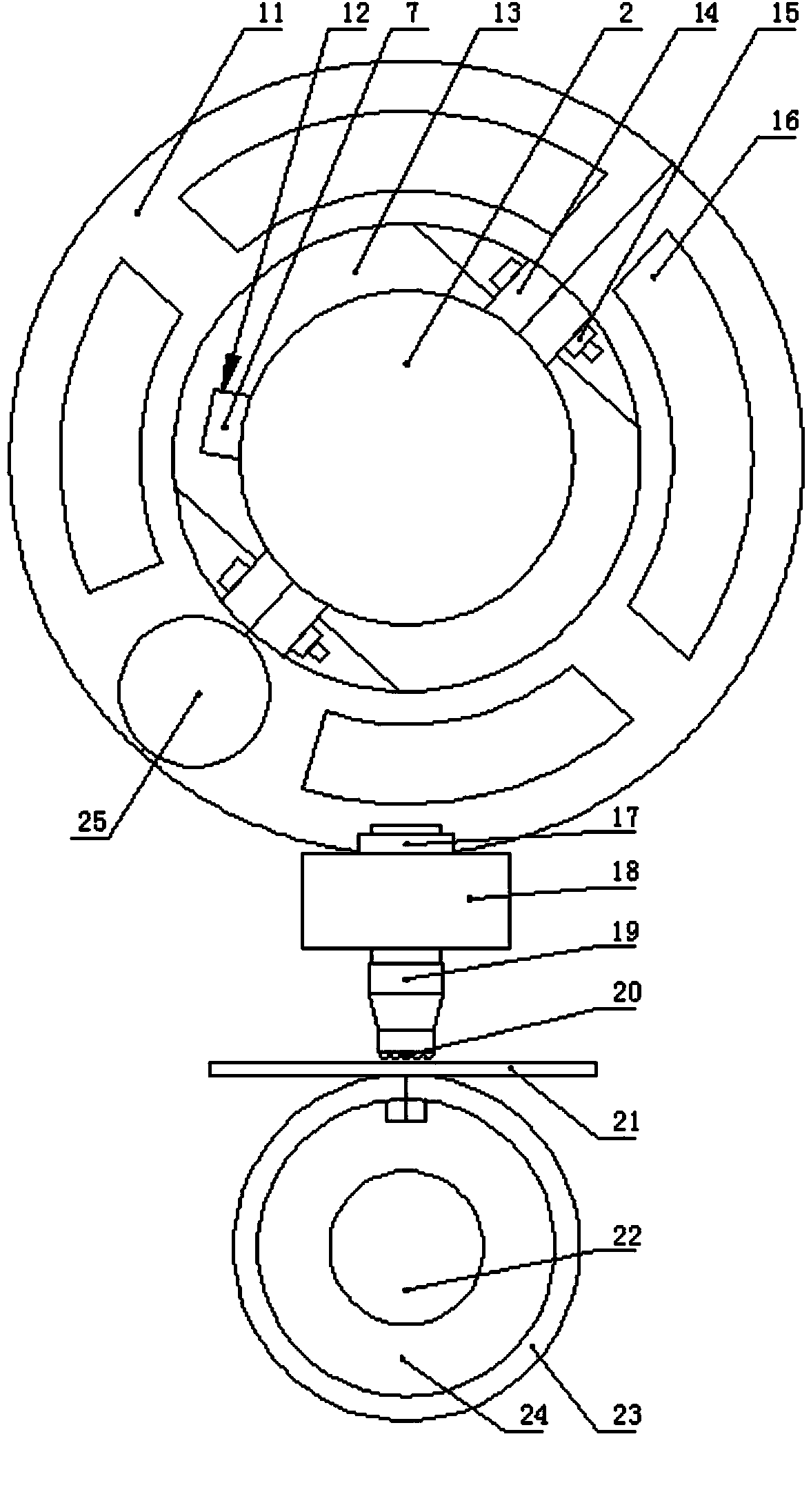

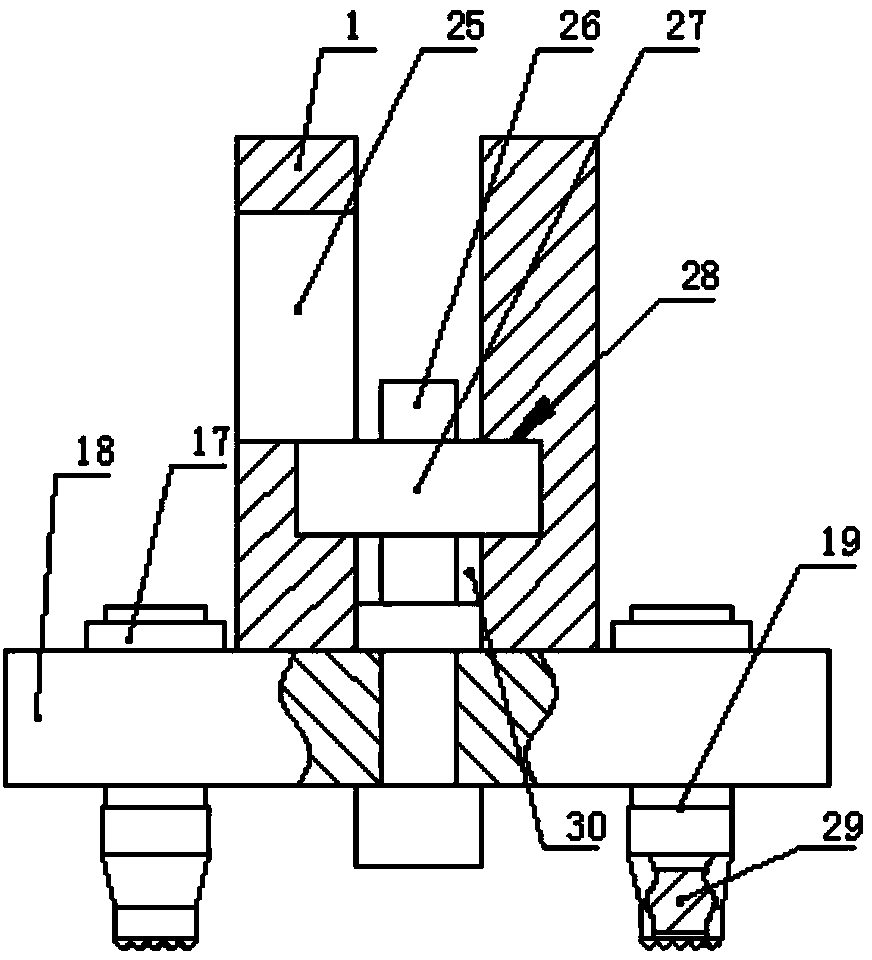

[0015] An ink printing slotting machine with a hole opening device, such as Figure 1~3 As shown, it includes a plurality of mobile cabinets 1, a slit roller 2 is installed on the mobile cabinet at the rear end, and a plurality of tool holders 3 are installed at intervals on the slit roller. The innovation of the present invention lies in: on the slit roller next to the tool holder The coaxial sleeve is provided with a hole opening device 4, which includes a mounting plate 11, a base 18, and a cylindrical cutter 19. The racks 7 mounted on the rollers are buckled together, and the base is installed horizontally on the outer edge of the mounting plate. Two cylindrical cutters are symmetrically installed on both sides of the base, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com