Straw cutting speed and length adjustable cylinder cutter

A cutting speed and cutting length technology, applied in the field of straw resource utilization devices, can solve the problems of uneven cutting force, high labor intensity, low degree of automation, etc., to avoid over cutting or no-load cutting, high cutting pass rate, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] The cutter device of the present invention can control and detect the rotating speed of the drum and the belt through the PLC controller and the sensor, so that the cutting speed and the cutting length can be adjusted.

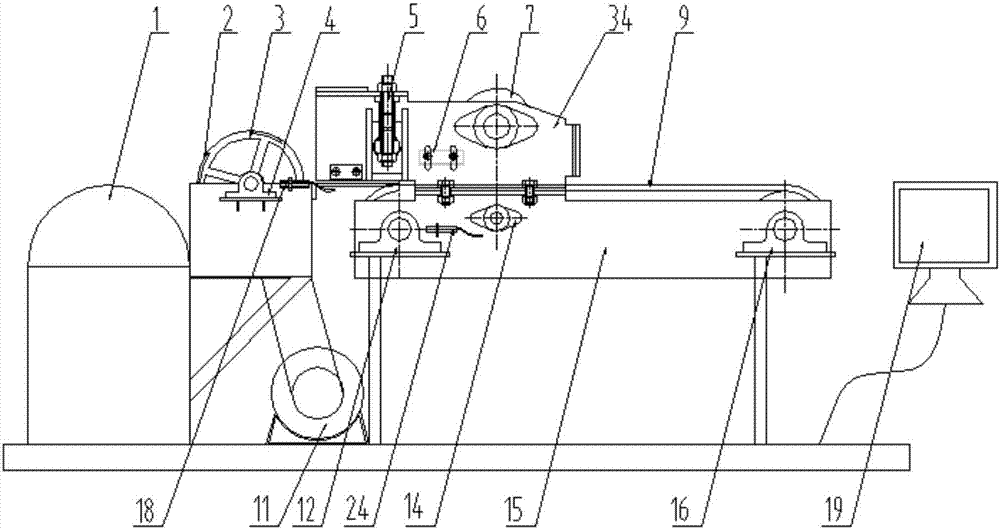

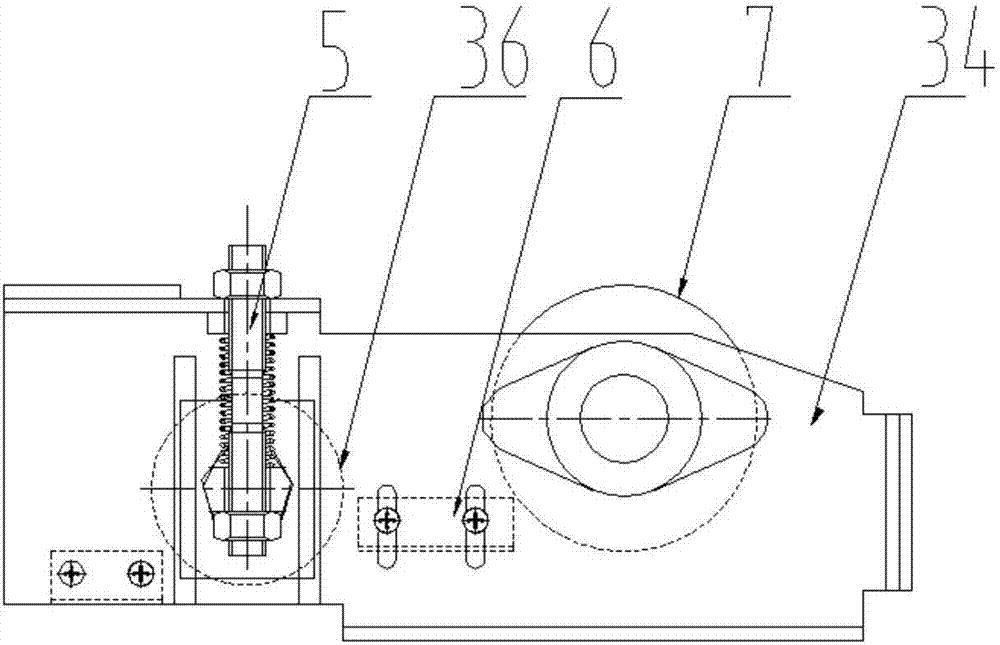

[0048] Such as figure 1 As shown, a drum-type cutter with adjustable cutting speed and cutting length is composed of a drum-type cutting device, a pressing type feeding device, a cutting parameter testing unit, a cutting parameter adjustment driving motor and a driving board, a control display unit and components such as power supply;

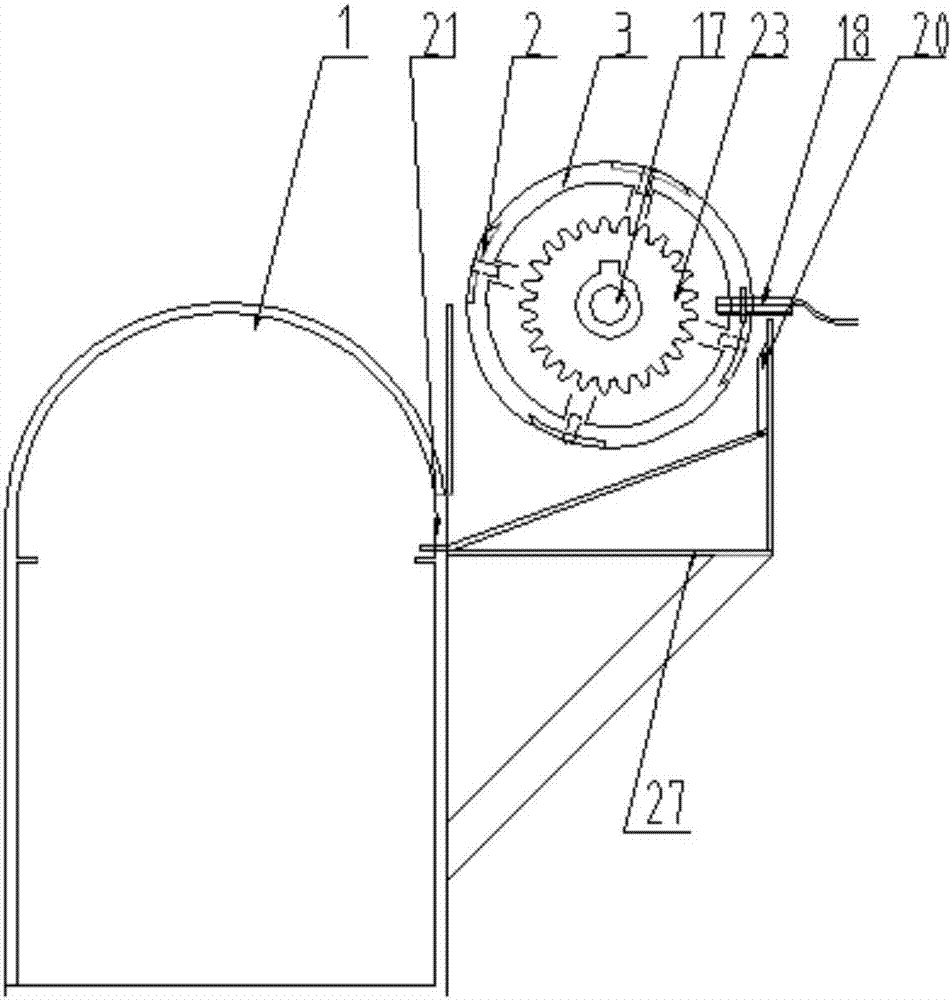

[0049] Such as figure 1 As shown, the drum cutting device mainly includes a discharge port 1, a helical cutting knife 2, a rotating drum 3 with a moving knife installed, a horizontal cutting knife 20, a bracket 21, a UCP bearing seat 4 and a drive shaft 17. Among them, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com