Method and equipment enabling air compressor to achieve constant-pressure air supply

A technology of air compressors and equipment, which is applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc. It can solve the problems of large fluctuations in air supply pressure, not constant, and inability to adjust the air supply volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

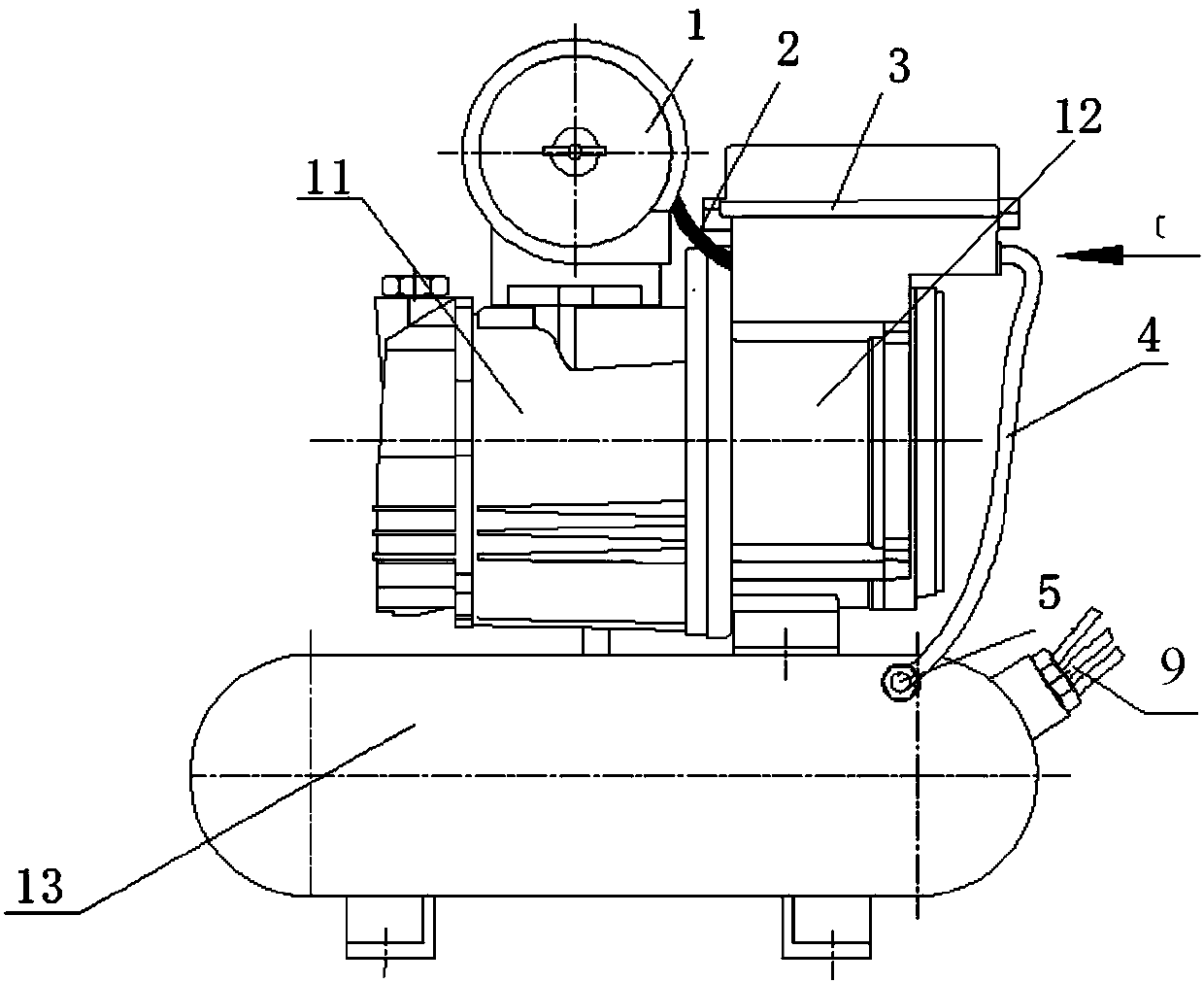

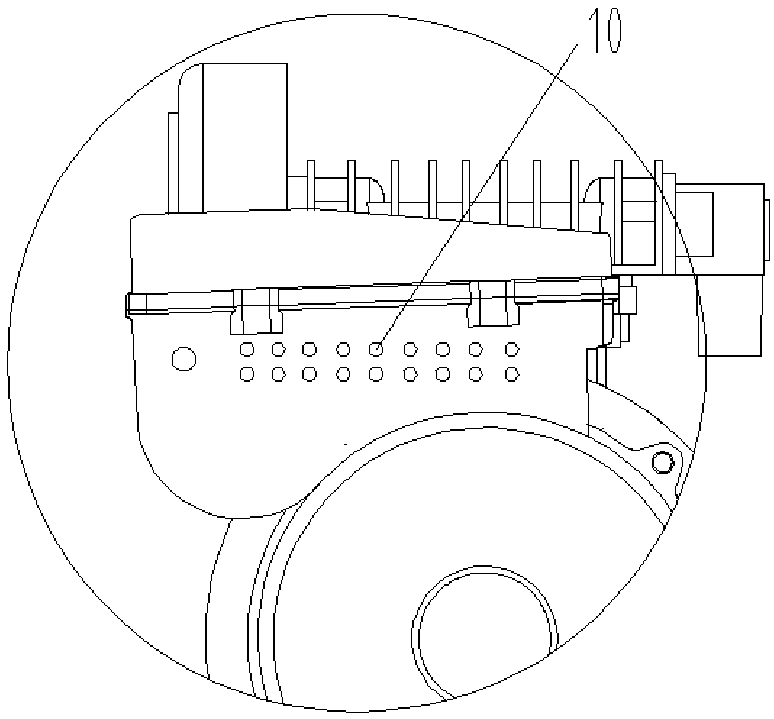

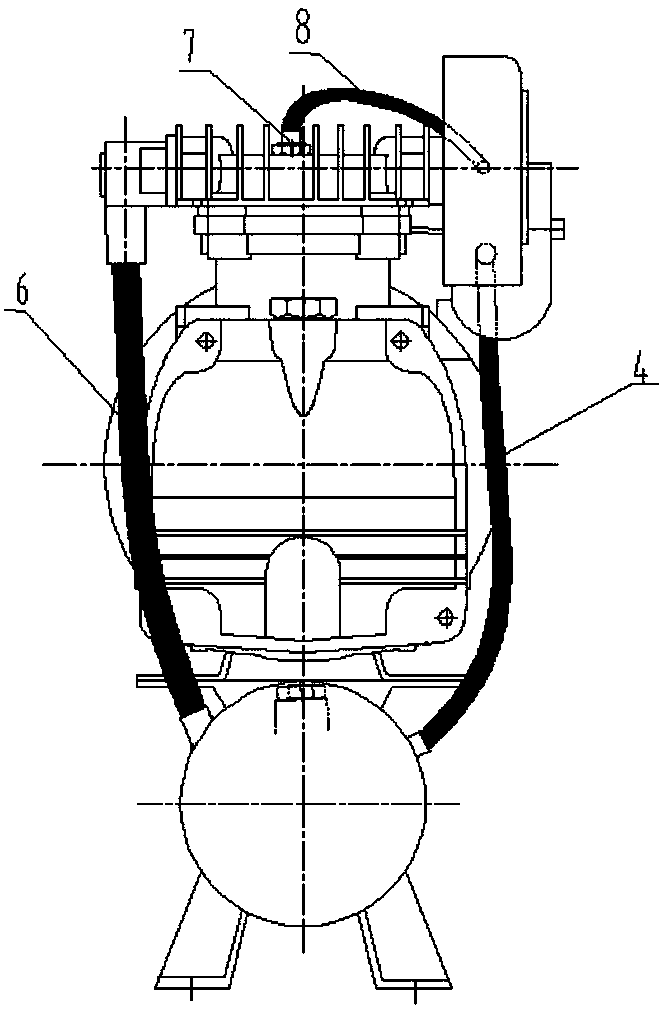

[0041] see Figure 1-Figure 7 , a method of the present invention to enable the air compressor to achieve constant pressure gas supply, comprising: the air compressor 11 compresses and outputs gas; the gas storage tank 13 connected to the output end of the air compressor 11 receives the gas compressed by the air compressor and Supply gas to the user; the pressure sensor 5 connected to the gas storage tank 13 detects the air supply pressure in the gas storage tank 13, and outputs a pressure detection signal; the controller connected to the pressure sensor 5 according to the rated air pressure value P0 and The difference of the pressure P1 of the pressure detection signal output by the pressure sensor 13 generates a motor control signal; the variable frequency motor 12 connected between the controller and the air compressor 11 controls its driving air pressure according to the motor control signal output by the controller. The working speed of the air compressor, so that the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com