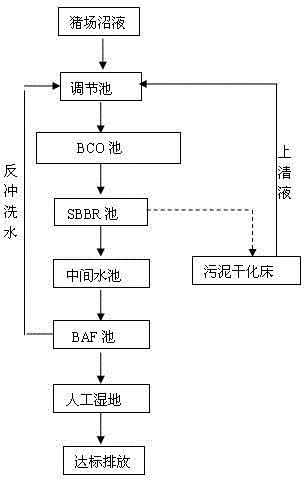

BCO-SBBR-BAF-CW combination technology for processing pig farm biogas slurry

A technology of BCO-SBBR-BAF-CW combined process, which is applied in the field of environmental science and engineering, can solve the problems of large infrastructure investment, large land occupation, and large climate impact, and achieve low operating costs, small land occupation, and Guaranteed continuity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] After anaerobic treatment of wastewater from a large-scale pig farm, biogas slurry CODcr, BOD 5 , SS, NH 3 -N and TP are respectively: 568~1810 mg / L, 112~326 mg / L, 268~749 mg / L, 366~1450 mg / L, 19.0~44.8mg / L, and the treatment scale is 150m 3 / d. The pig farm biogas slurry first flows into the regulating tank to remove some organic matter and suspended matter, and then is pumped to the denitrification area of the BCO pool for denitrification reaction, and then flows into the nitrification area to further remove organic matter and carry out nitrification reaction, and overflows to the SBBR pool. The operation mode of SBBR is: aeration for 4 hours, anoxic for 2 hours, aeration for 4 hours, sedimentation for 1 hour, and drainage for 1 hour. The water flows into the BAF pool and artificial wetland for advanced treatment to further remove organic matter, nitrogen, phosphorus and suspended matter. CODcr, BOD in water after treatment by the device 5 , SS, NH 3 The averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com