Heat Dissipation Methods for Switching Power Supplies

A technology of switching power supply and heat dissipation method, which is applied in the modification of power electronics, electrical components, and structural parts of electrical equipment, etc., can solve the problem that the heat dissipation device cannot adjust the air volume, etc., to improve the mean time between failures, reduce noise, and reduce startup. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

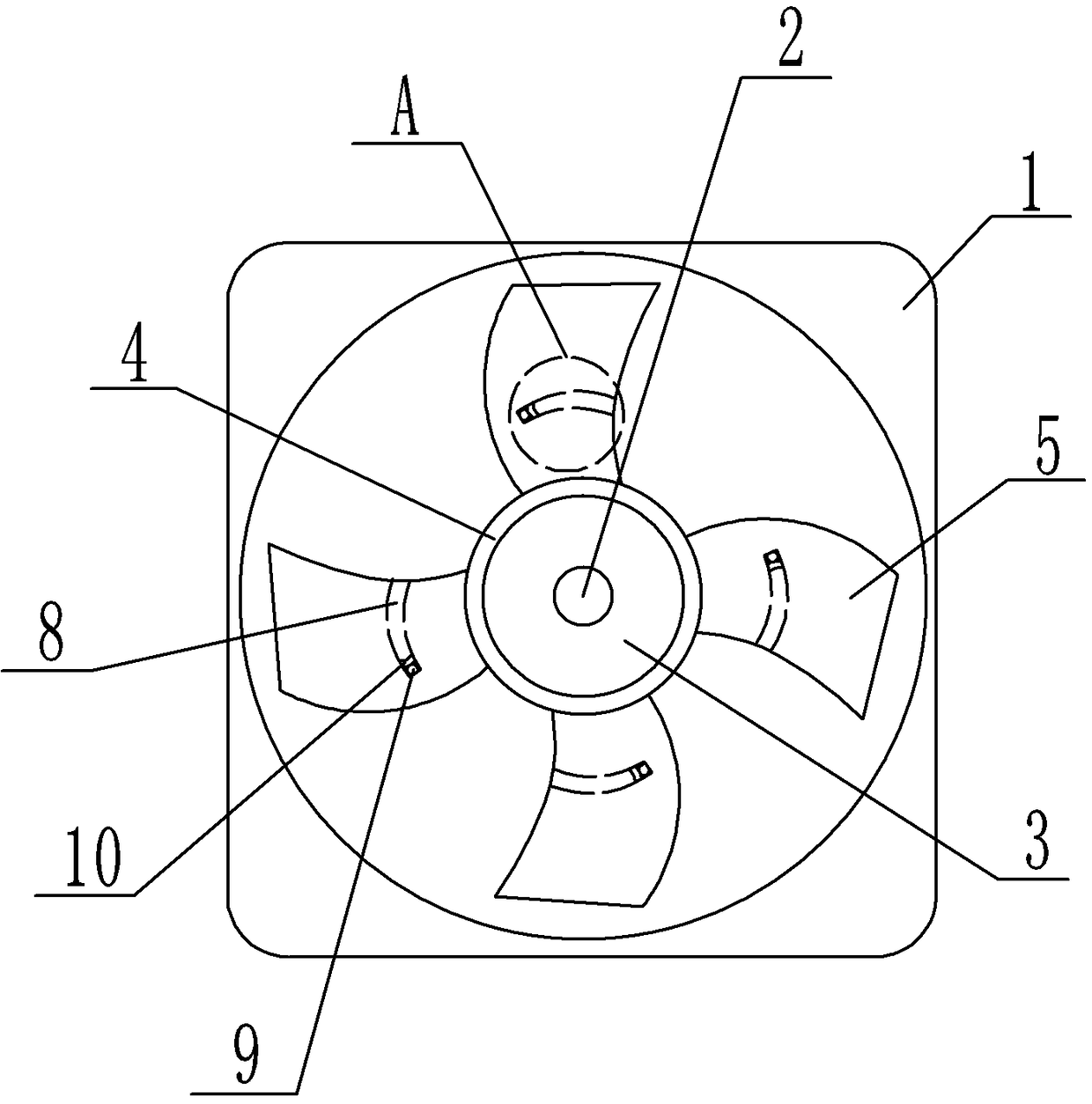

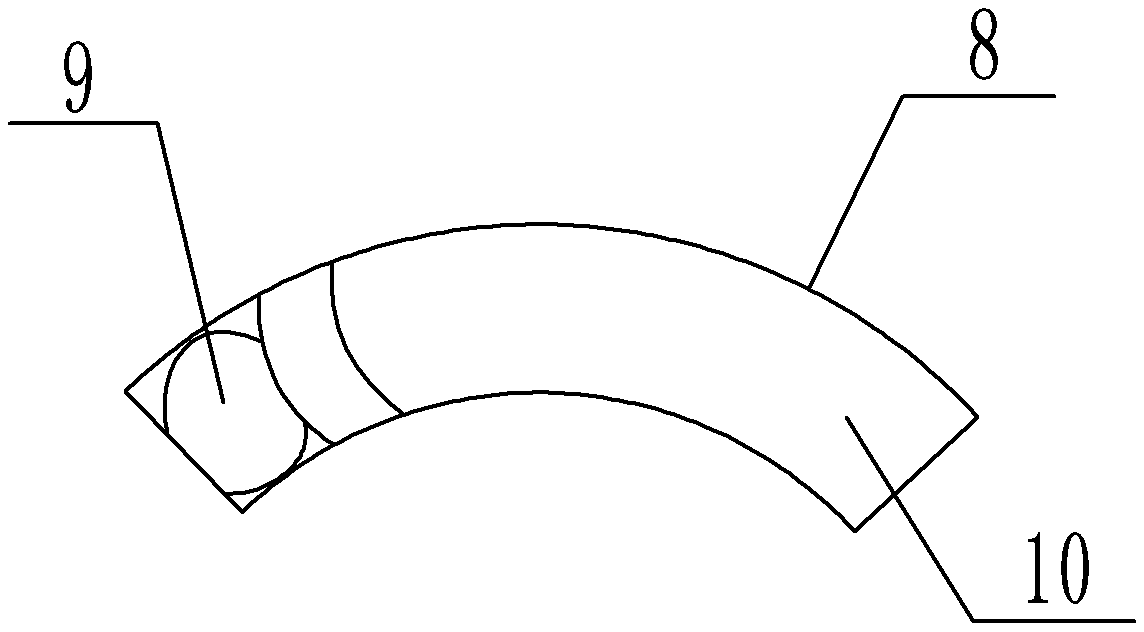

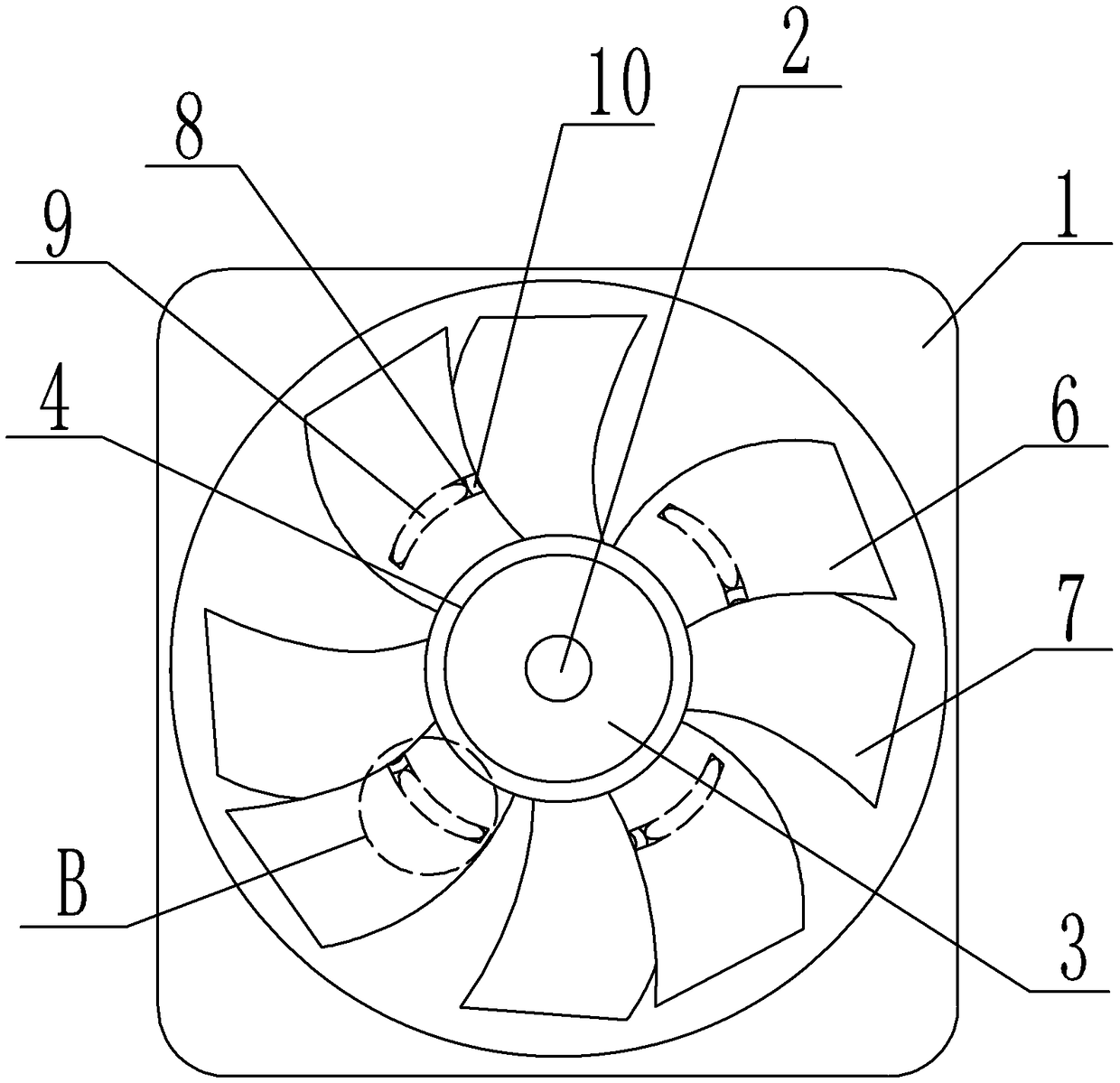

[0027] The reference numerals in the accompanying drawings include: fan frame 1 , stator 2 , rotor 3 , hub 4 , blade set 5 , upper blade 6 , lower blade 7 , chute 8 , airbag 9 , and slider 10 .

[0028] The embodiment is basically as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0029] Heat dissipation methods for switching power supplies, including the following:

[0030] 1) When the switching power supply is working, the cooling fan starts to rotate. As the working time of the switching power supply becomes longer, the temperature of the heating element in the switching power supply rises. The gas generated by the boiling of vinegar makes the airbag expand, and the inflated airbag pushes the slider on the lower fan blade to slide on the chute, so that the upper fan blade and the lower fan blade of the fan blade group are staggered, and the air volume generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com