Safety separating device for shell and grain of small-sized composite solid rocket engine

A technology for engine shells and solid rockets, which is applied to rocket engine devices, machines/engines, jet propulsion devices, etc. It can solve problems such as difficult recycling and reuse, and achieve the effects of small equipment investment, high efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

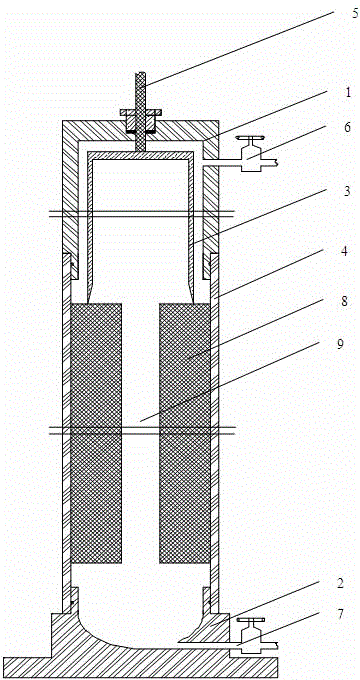

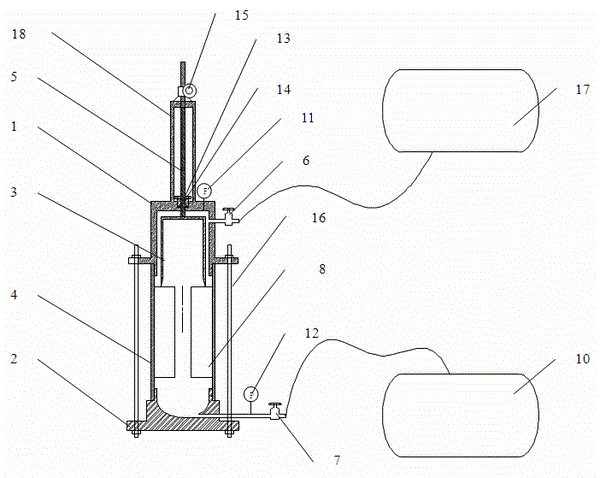

[0023] figure 1 Among them, the present invention includes an upper seal seat 1 on the engine case, a lower seal seat 2 on the engine case, and a cylindrical knife 3; the upper seal seat 1 on the engine case is connected to the solid rocket motor case 4 by sealing; There is an adjustable liquid inlet valve 6; the lower sealing seat 2 of the engine case is sealed and connected with the solid rocket motor case 4; there is an adjustable liquid outlet valve 7 on the lower sealing seat 2 of the engine case; the cylindrical knife 3 It is a cylindrical part with one end closed and the other end sharpened, which is connected with the push rod 5; the push rod 5 is a dynamic seal with the seal seat 1 on the engine case; the push rod 5 can move up and down relative to the seal seat 1 on the engine case . When a certain pressure is added to the push rod 5, the push rod 5 can push t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com