Ultrasonic vibration drill hole tail end actuator

An end effector and ultrasonic vibration technology, applied in the field of robot hole making, can solve the problems of large vibration transmission loss, hidden dangers of processing safety, chips being involved between two magnetic rings, etc., to improve processing quality and efficiency, and improve processing efficiency , the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

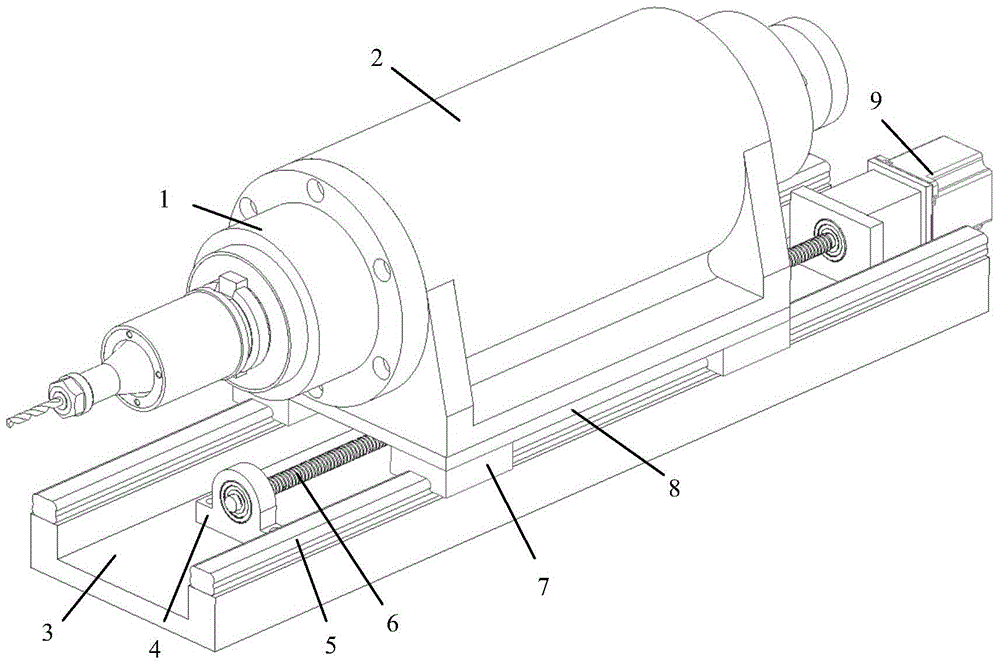

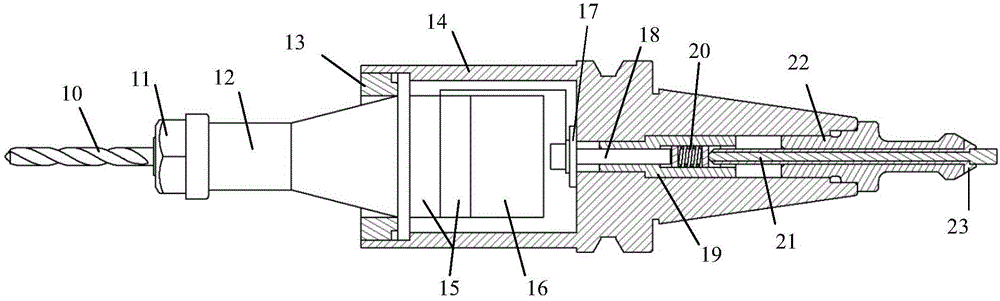

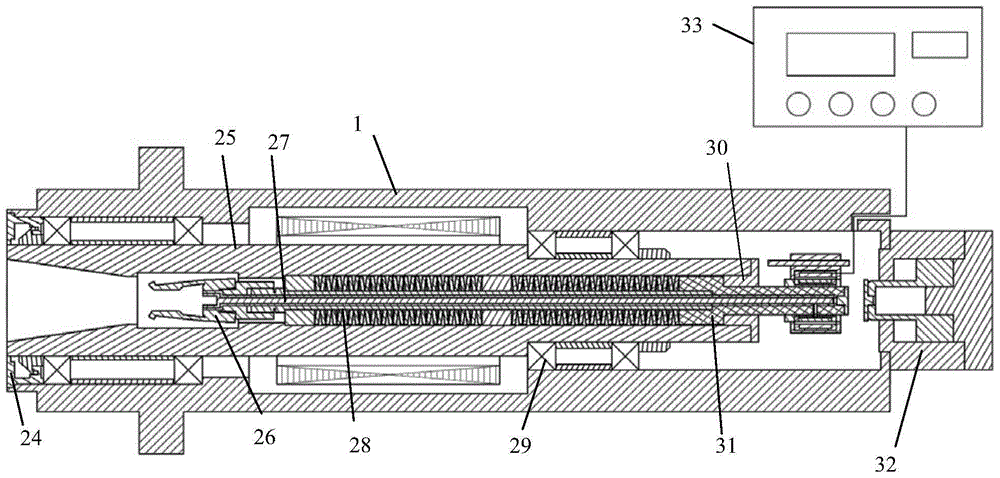

[0022] Such as Figure 1-Figure 5As shown, an ultrasonic vibration drilling end effector includes a main shaft unit, an ultrasonic tool handle unit and a feed unit. The main shaft unit includes an electric spindle housing 1 and a spindle rotor 25 supported inside the electric spindle housing 1 through a bearing 29 , the front end of the electric spindle casing 1 is provided with a spindle end cover 24, the electric spindle casing 1 is fixed on the spindle support 2 through a flange and screws, the bottom plate 8 is fixed below the spindle support 2, and the bottom plate 8 is provided with Guide the slider 7, the spindle rotor 25 is provided with a spring rod 28 inside, the spring rod 28 includes a tubular rod member and an elastic member sleeved outside the rod member, the front end of the spring rod 28 is connected with the pull claw 26 , the rear end is connected with the spring rod connecting rod 31, and the inner hole of the rod member passing through the spring rod 28 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com