Plant feed crusher

A plant feed and pulverizer technology, applied in the field of aquaculture feed, can solve the problems of easily hurting their fingers, not easy to cut off, hurting people, etc., and achieves the effects of good pulverization effect, easy pulverization and reduction of accident rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

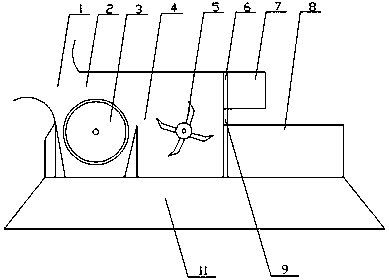

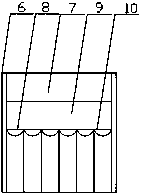

[0022] The present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-Figure 2 as shown, figure 1 It is a schematic diagram of the main viewing direction of the present invention. figure 2 It is a schematic diagram of the right view direction of the present invention.

[0023] The green fodder crushing device comprises a box body and a feeding platform 8, wherein a crushing chamber 2 and a cutting chamber 4 are arranged in the box body, and a feeding platform 8 is arranged on one side of the cutting chamber 4, and the height of the feeding platform 8 is the height of the box body. One side of the cutting chamber 4 is provided with a feed port 9, the feed port 9 is located above the feed table 8, and the top of the feed port 9 is provided with a pressing table 7, and the left and right sides of the feed port 9 A slideway 6 is provided on the side, a sliding connection between the pressing table 7 and the slideway 6, a fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com