Round section tubing slitting mill

A circular cross-section, rolling cutting machine technology, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of inability to realize automatic retraction movement, complex transmission system, and inability to work continuously, and achieve the goal of transmission mechanism Simple and reliable, increase cutting speed, use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

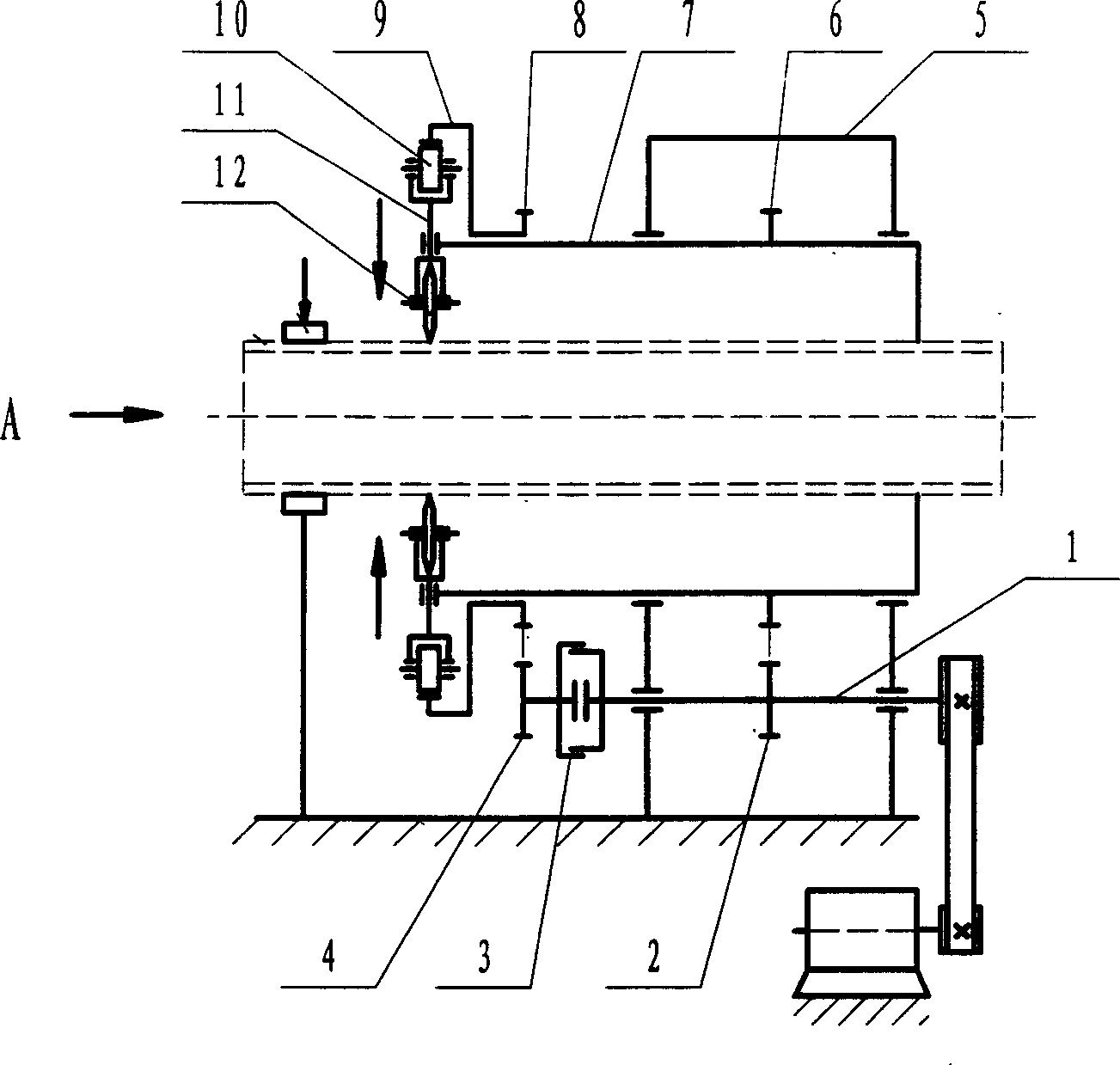

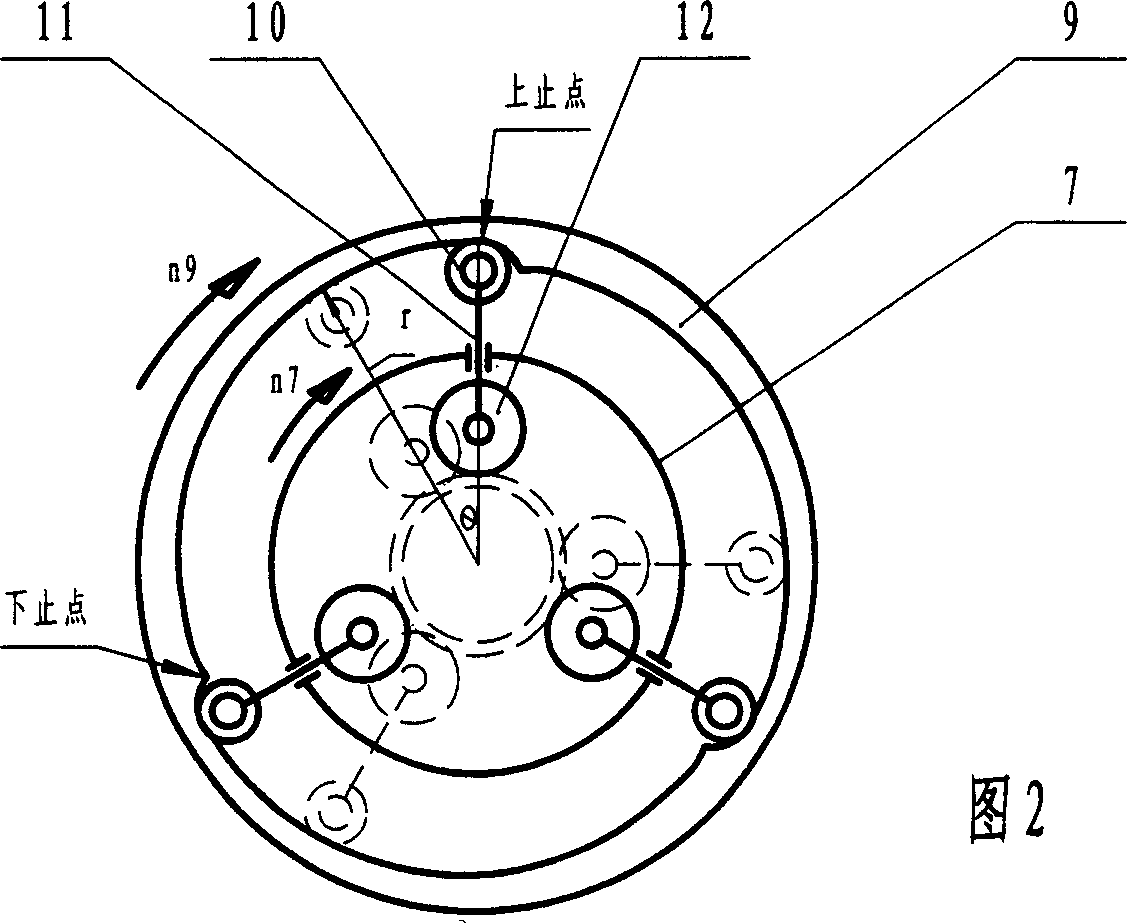

[0017] Depend on figure 1 The shown circular section pipe hobbing machine has a rotating cylinder 7 mounted on the frame 9 through bearings. A rotating ring 9 rotating with it is installed at the leading end of the rotating cylinder 7 . On the inner ring of the rotating ring 9 there is an inner cam formed by connecting Archimedes spiral segments with each other. The end-to-end connection of each segment is a transition connection end with different curvature radii. The rotating cylinder 7 is provided with a hobbing device. The hobbing and cutting device comprises a knife rest slider 11, the upper and lower ends of which are respectively provided with hinged rollers 10 and hinged disc cutters 12, and are movably mounted on the rotating cylinder 7 through the knife rest slider 11. Gears 6 and 8 are respectively provided on the rotating cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com