Four-side film laminator

A laminating machine and laminating technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of waste materials, etc., and achieve the effect of convenient use and beautiful processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

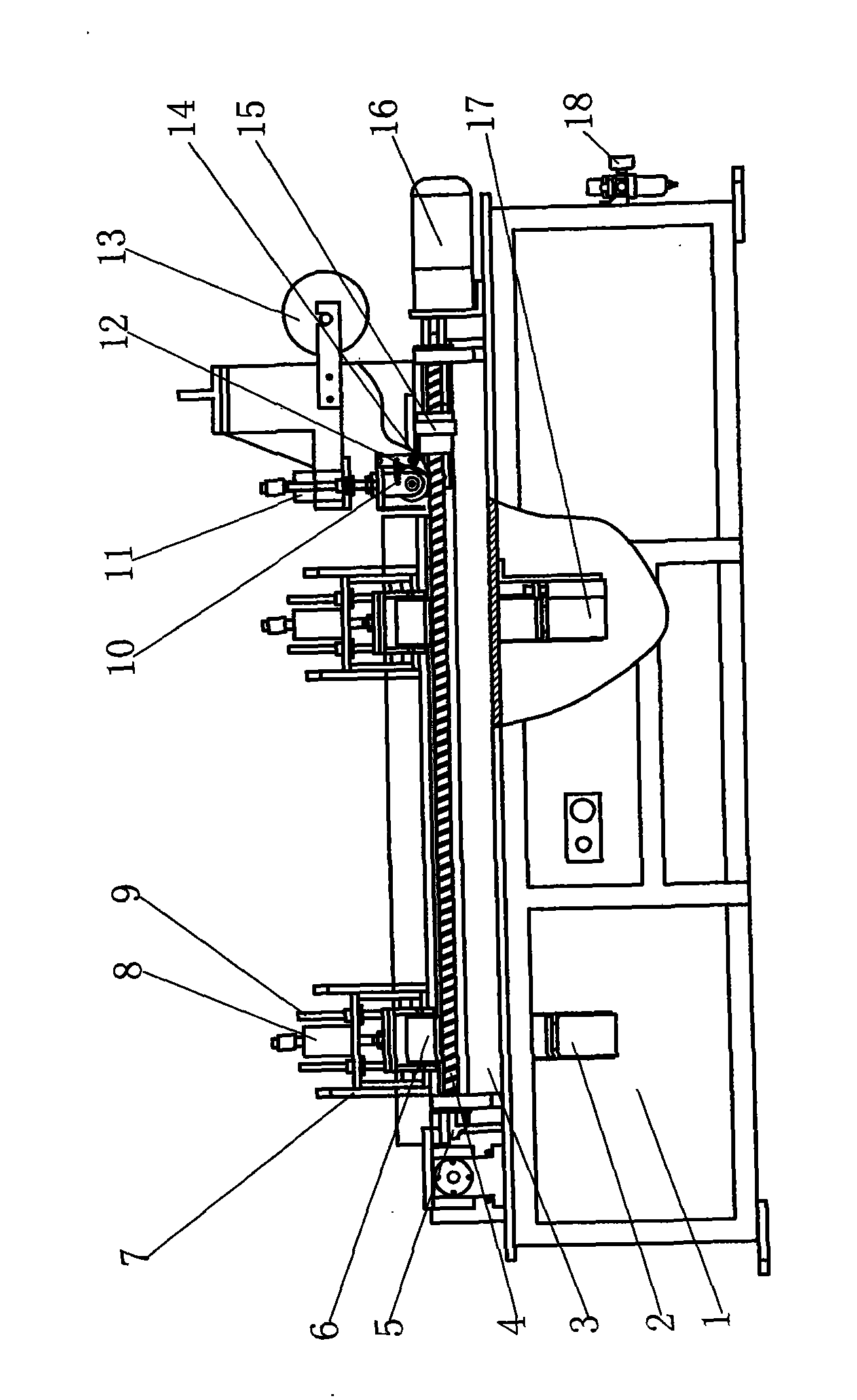

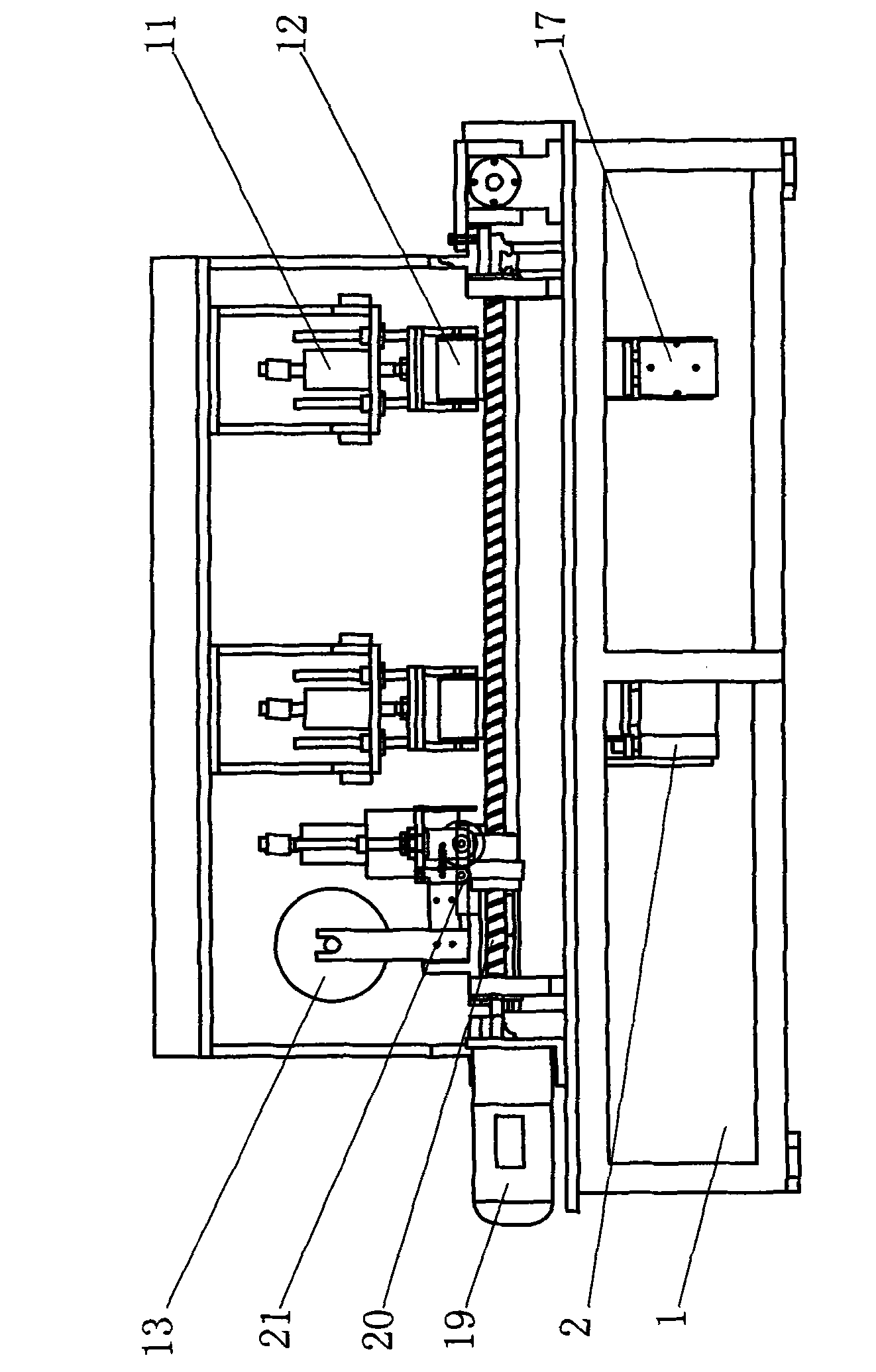

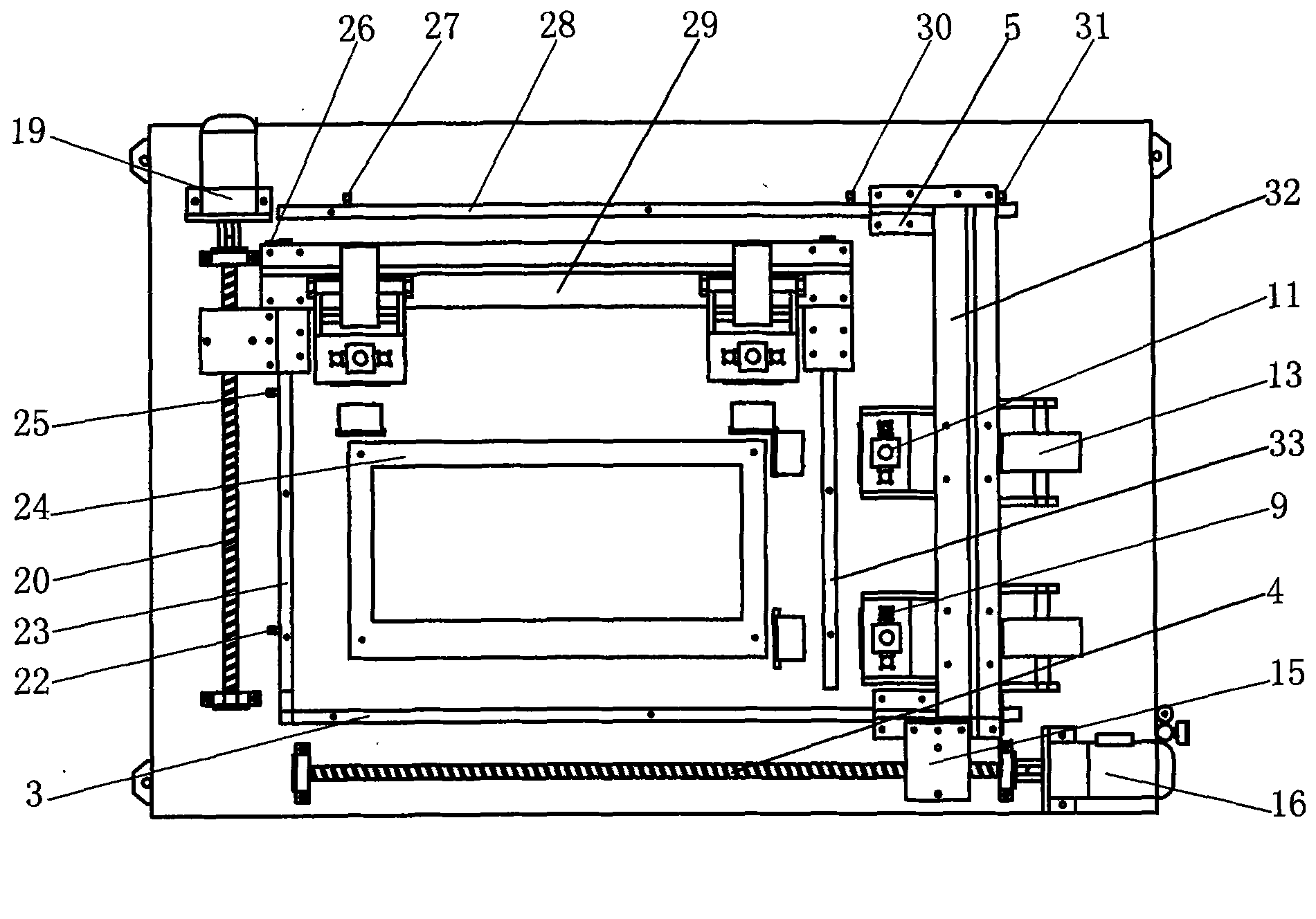

[0013] The present invention will be further described below in conjunction with the embodiments of the drawings.

[0014] As shown in the figure, a mold 24 is installed on the upper middle of the bottom box 1. A front rail 3, a rear rail 28, a left rail 23, and a right rail 33 are installed around the mold 24. A rail slider 5 and a front rail 3 are installed on the rails. A horizontal push rod 32 is installed between the slider 5 of the rear rail 28, a longitudinal push rod 29 is installed between the slider 5 of the left rail 23 and the right rail 33, and the lower part of the horizontal push rod 32 is equipped with front and rear laminating roller racks. 7. The upper part of the longitudinal push rod 29 is equipped with left and right coated roller racks 7; the outer side of the front rail 3 is equipped with a horizontal screw 4, the outer side of the left rail 23 is equipped with a longitudinal screw 20, and the longitudinal screw 20 is on the horizontal screw 4. Equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com