Double-groove cylinder cutter

A slotted and cylindrical technology, applied in the field of woodworking slotting knives, can solve the problems of short tool life, burrs, and low work efficiency, and achieve the effect of cutting lightly, saving costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

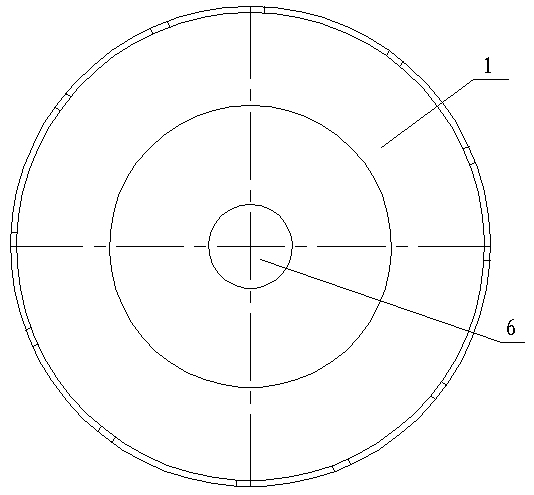

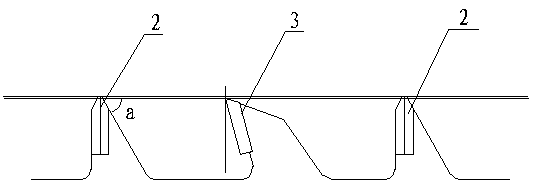

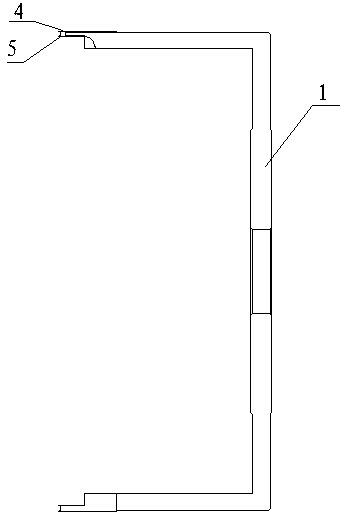

[0019] The structure of the double-groove cylindrical knife of the present invention is as follows: Figure 1-8 As shown, it is composed of a first cutter body 1 and a second cutter body 7, the second cutter body 7 is installed inside the first cutter body 1, and the first cutter flat edge 3 and the first cutter body 1 are evenly spaced on the circumference of the first cutter body 1. The first cutter hair leading edge 2, the first cutter hair leading edge 2 is provided with the first cutter left hair leading edge 4 and the first cutter right hair leading edge 5; the second cutter concrete 7 is evenly spaced on the circumference of the second cutter flat edge 9 And the second cutter hair leading edge 8, the second cutter hair leading edge 8 is provided with a second cutter left hair leading edge 10 and a second cutter right hair leading edge 11. The tooth tip heights of the first tool leading edge 2 and the second tool leading edge 8 are 0.5 mm higher than the heights of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com