Method for implementing low power consumption suspension of five-freedom degree magnetic suspension system axial magnetic bearing

An axial magnetic bearing and magnetic suspension technology, applied in the direction of shaft and bearing, bearing, mechanical equipment, etc., can solve the problem of excessive displacement deviation error signal, and achieve the effect of low power consumption and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

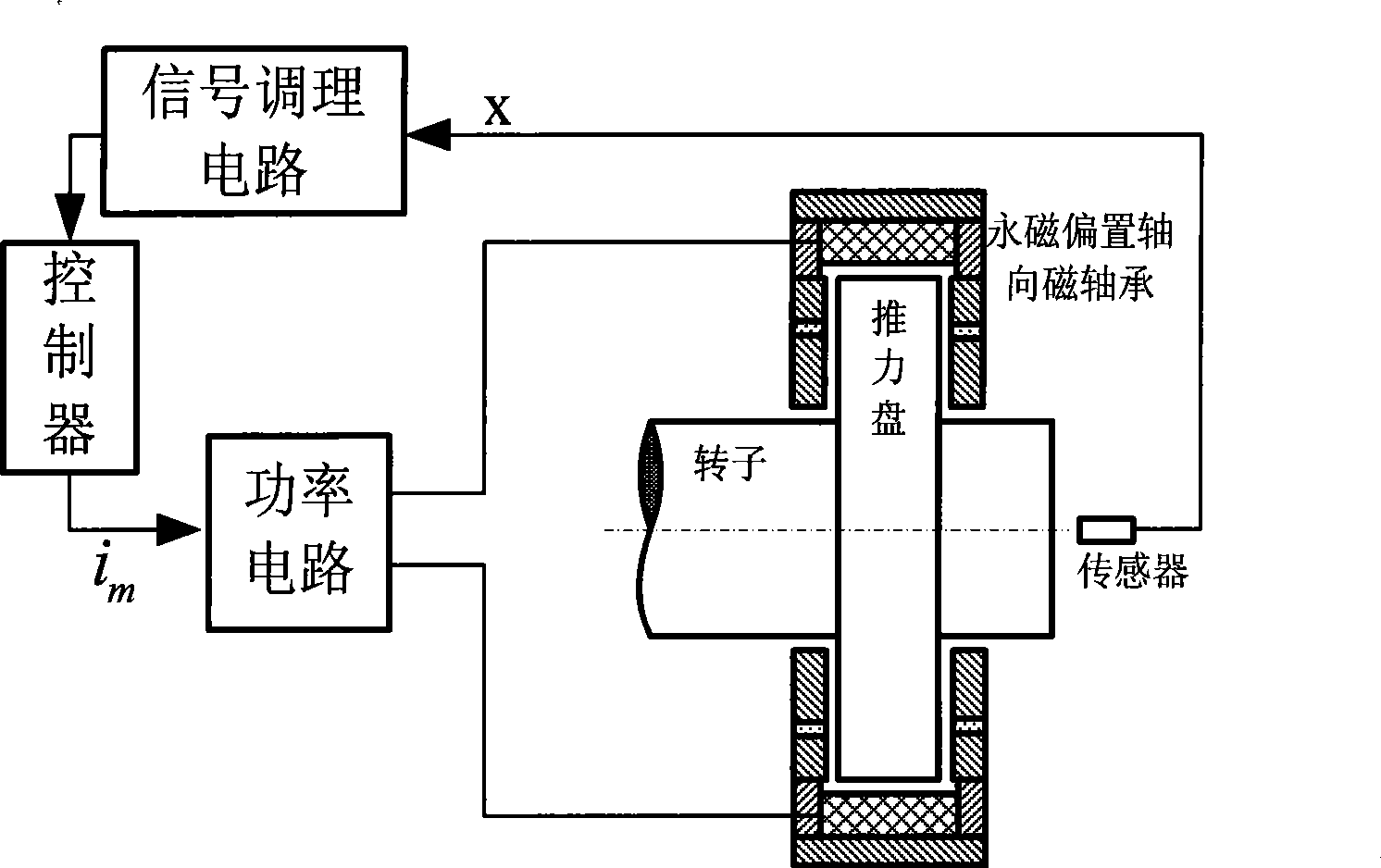

[0022] Permanent magnet bias axial magnetic bearing control coil control circuit part such as figure 1 As shown, including signal conditioning circuit, power circuit and controller. The signal conditioning circuit converts the axial displacement signal of the rotor into a voltage signal that the controller can receive. The power circuit supplies current to the axial control coil of the permanent magnet bias axial magnetic bearing. The controller receives the axial position signal and uses The low-power displacement compensation algorithm generates corresponding control signals to control the power circuit.

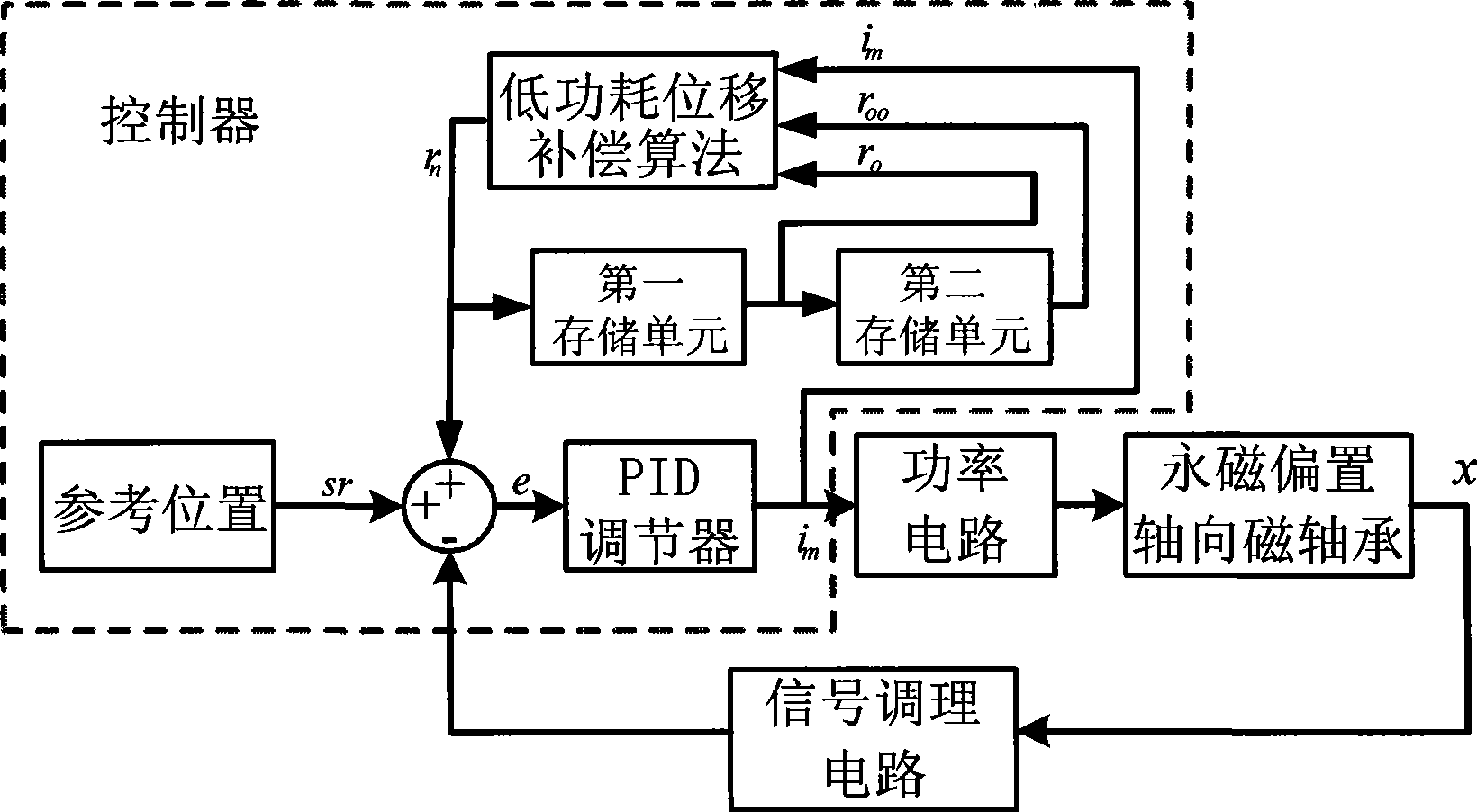

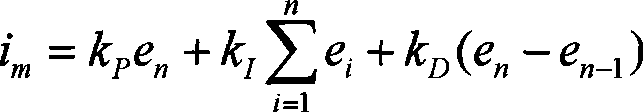

[0023] The permanent magnet bias axial magnetic bearing control coil realizes axial low power consumption levitation. The realization method is as follows: figure 2 As shown, the low-power magnetic bearing axial degree of freedom negative feedback closed-loop control system includes the suspension position of the given rotor in the controller, that is, the reference posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com