Substrate constant temperature technology for preparing direct current arc discharge PCVD diamond film

A diamond film, arc discharge technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem that the substrate temperature cannot be guaranteed, and achieves good disassembly performance, convenient experimental process, and good linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

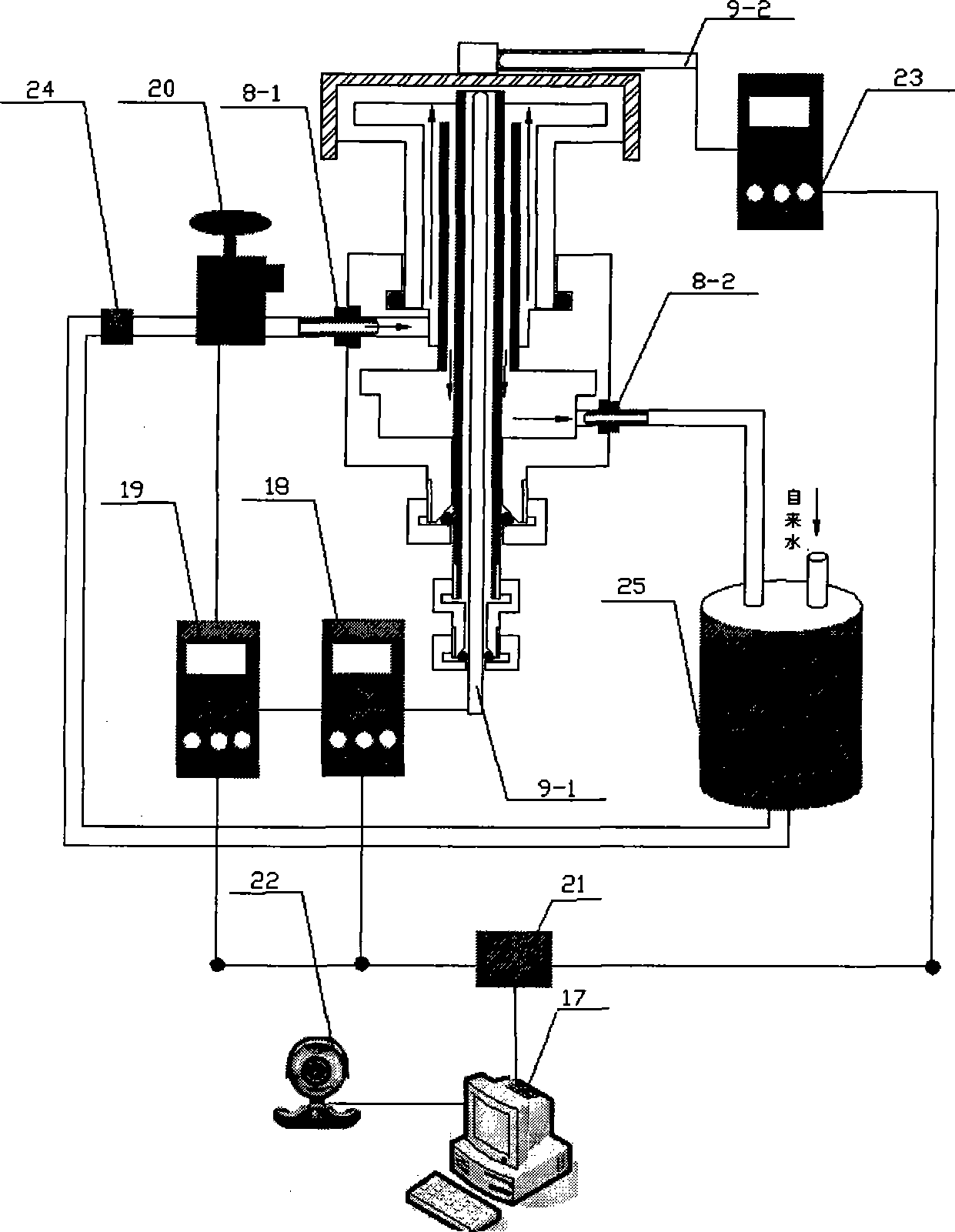

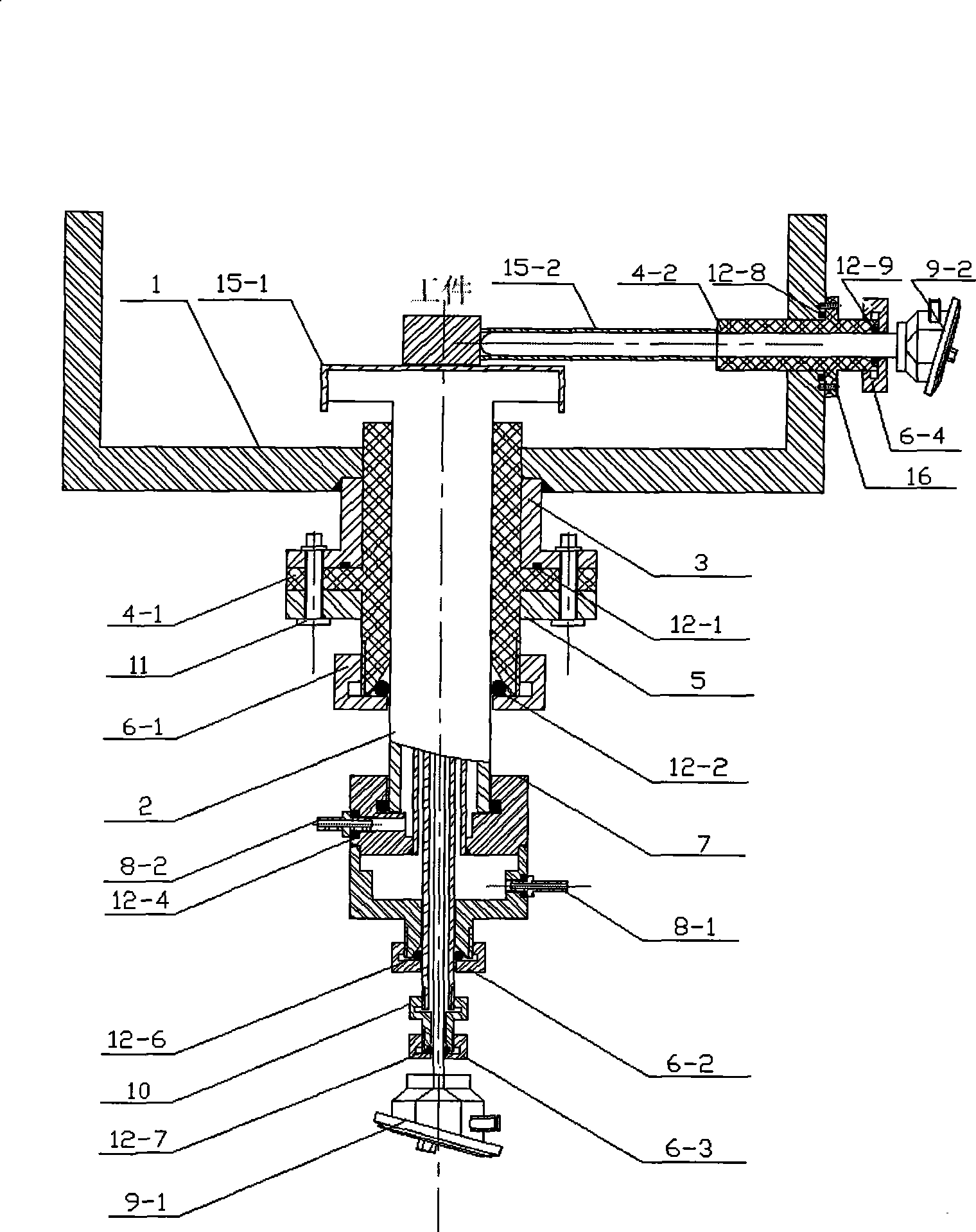

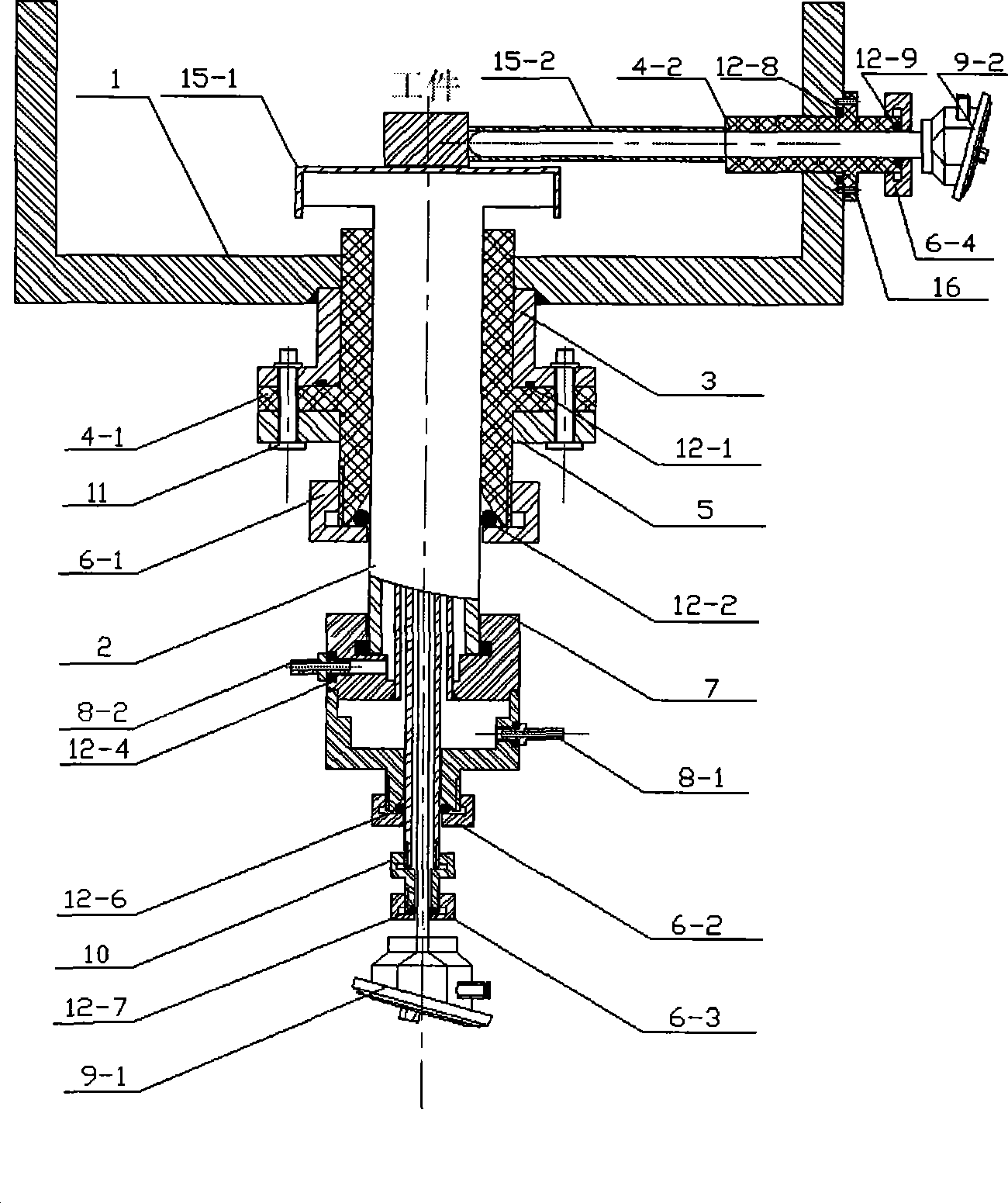

[0028] The present invention adopts automatic constant temperature device (as figure 1 ) and double thermocouple temperature technology, the substrate temperature in the preparation of DC arc discharge PCVD diamond film was measured and controlled. Now in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] A. Double thermocouple temperature measurement and temperature comparison

[0030] Such as figure 1 , shown in 2, 3, and 4, the armored thermocouple (9-1) is installed in the thermocouple sleeve (14) inside the water-cooled base bracket device (2), and the armored thermocouple (9-2) is installed in the The flat head screw (16) and the "O" type sealing ring (12-8) are fixed in the polysulfone flange (4-2) on the right side of the reaction chamber (1), and the "O" type sealing ring (12-9 ), lock nuts (6-4) are fixed, and the two are used to measure the temperature of the back and side parts of the substrate workpiece respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com