Control system and method for improving the rapid boiler adjusting capability of unit generating set

A technology of control system and generator set, applied in the direction of electric fluid pressure control, etc., which can solve problems affecting the safe and stable operation of power plant boilers, vibration divergence, and long time for operating pressure to stabilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

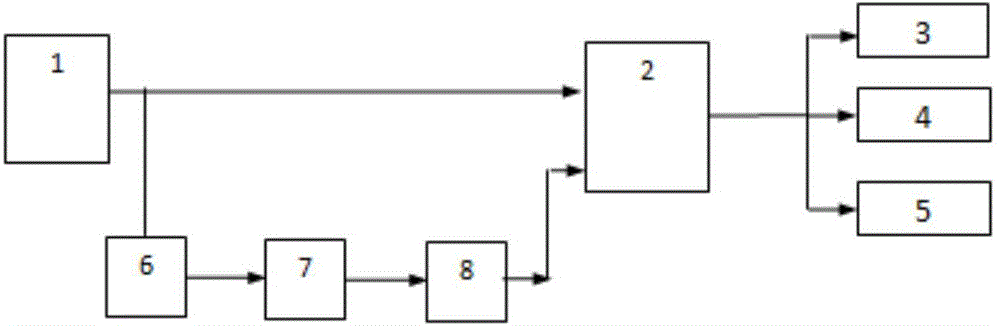

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

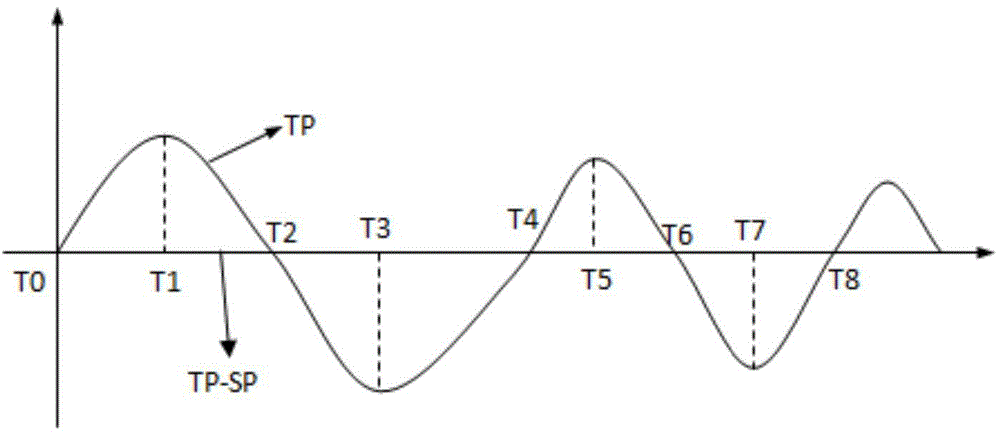

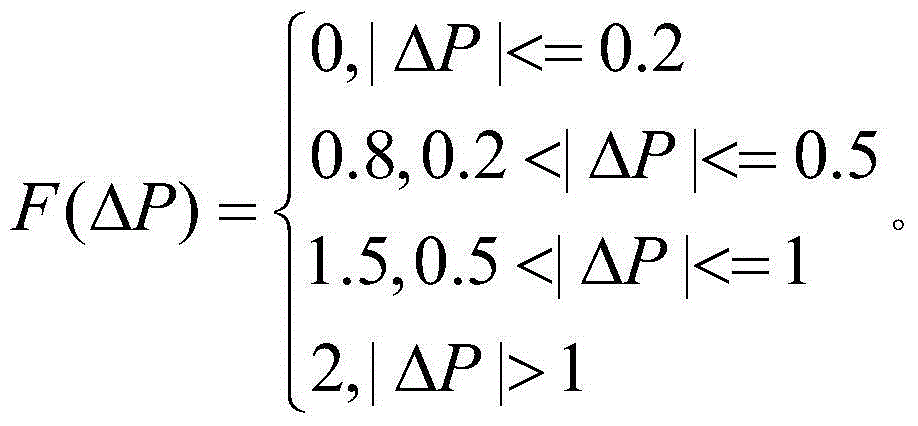

[0044] In order to meet the requirements of rapid adjustment of unit load for unitary thermal power generation units, the automatic control system is generally designed as a coordinated control method based on boiler follow-up. According to the safe and stable operation requirements of the unit, the steam pressure adjustment of the unit operation is mainly completed by the boiler adjustment output.

[0045] At present, due to the influence of factors such as fuel quality and unit operation mode in thermal power production enterprises, when the unit quickly adjusts the power generation load, the steam parameters of the unit change greatly, especially the main steam pressure, main steam temperature and other important parameters that affect the safe operation of the unit. big. At this time, if the boiler cannot adjust the output in time and quickly to stabilize the operating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com