Automatic control method for top pressure of TRT (blast furnace top gas recovery turbine unit) system

A blast furnace gas and power generation device technology, applied in blast furnace, blast furnace details, engine components, etc., can solve problems such as low accuracy and power generation efficiency, inaccurate valve characteristic data, low blast furnace top pressure stability, etc., and achieve stable control. The effect of blast furnace top pressure, improving accuracy and reducing blast furnace top pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

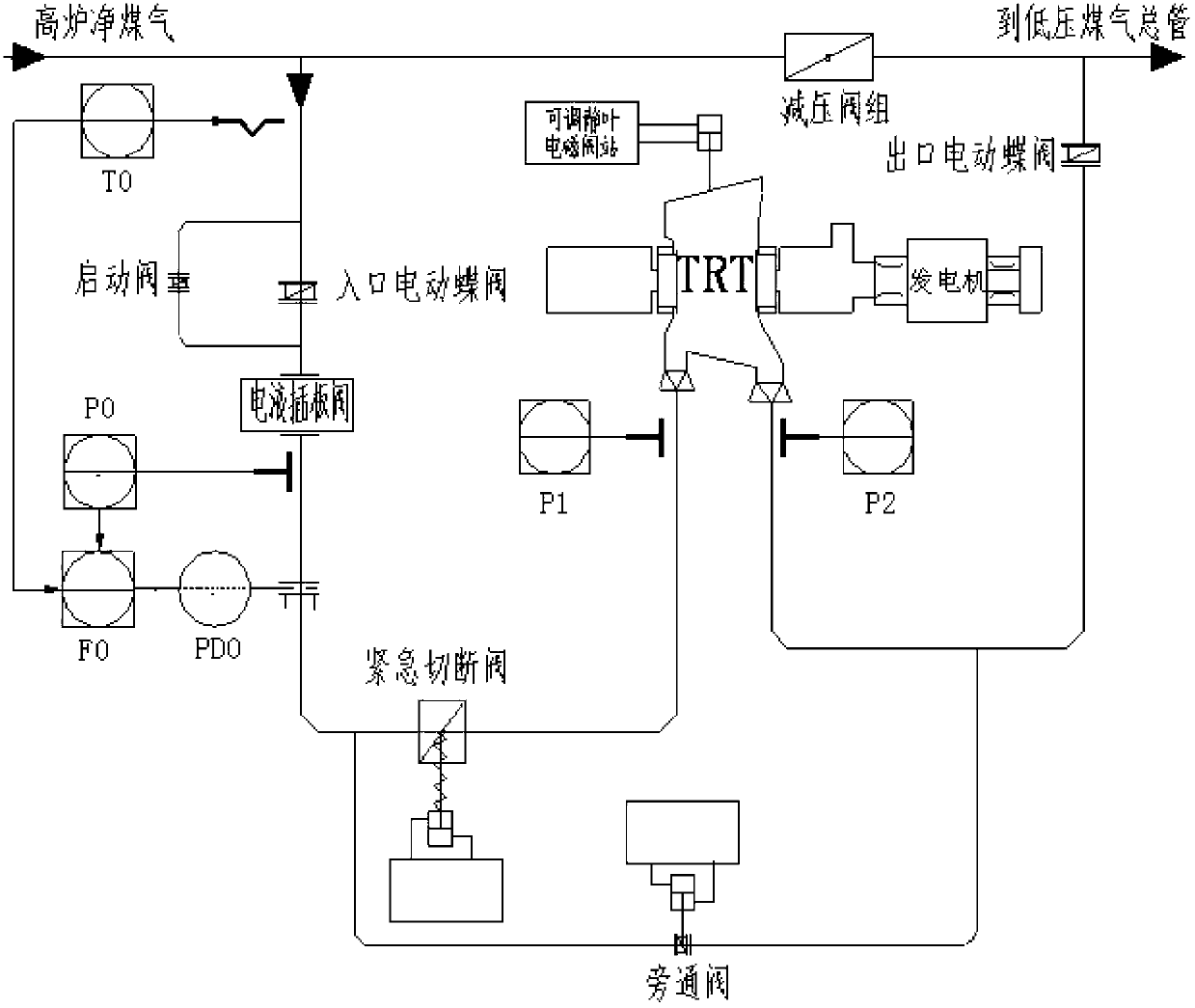

[0031] figure 1 It is a system process flow and instrument location diagram of an embodiment of the present invention: blast furnace smelting gas enters the TRT system after dedusting. Through the starting valve, the inlet electric disc valve, the inlet electro-hydraulic flapper valve, the emergency shut-off valve, and the TRT vane, the turbine expands and works, driving the generator to generate electricity. The gas from the turbine enters the low-pressure pipe network, It is connected in parallel with the pressure reducing valve group in the gas system. The bypass valve is connected in parallel with the emergency cut-off valve and the vane.

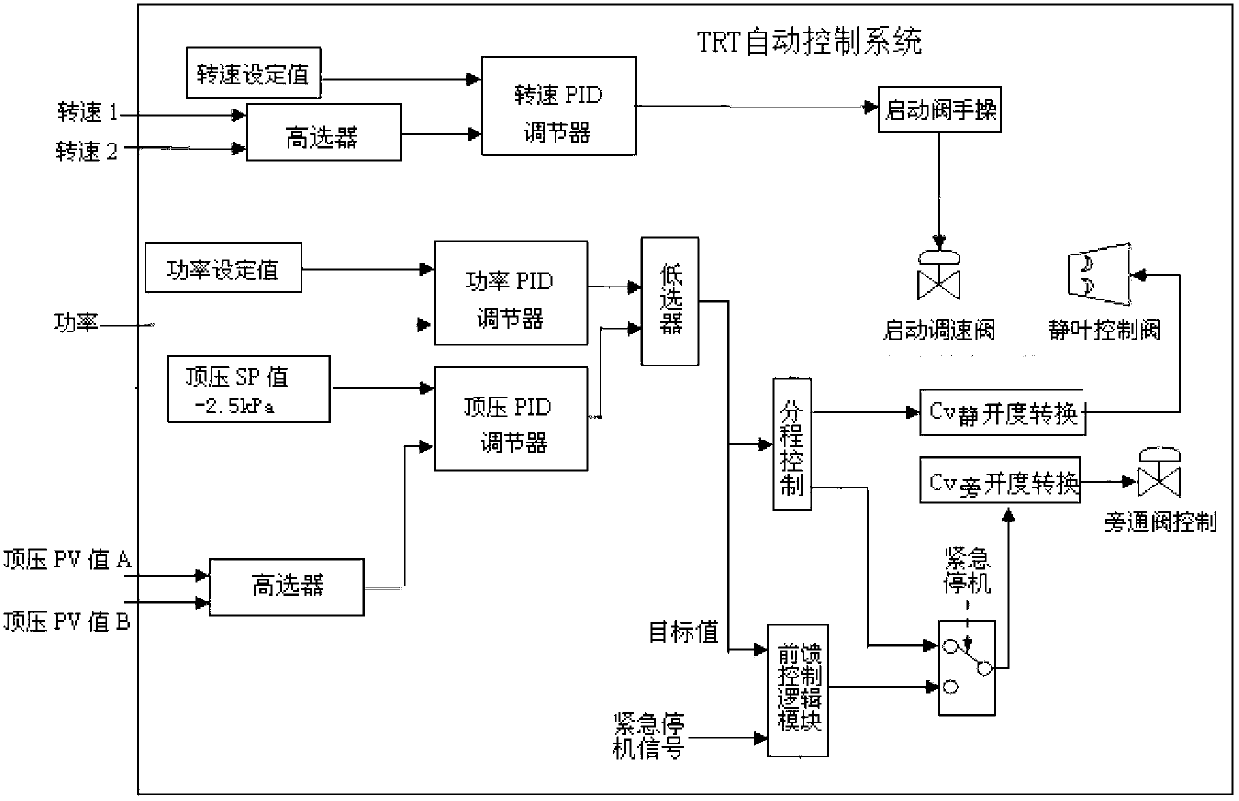

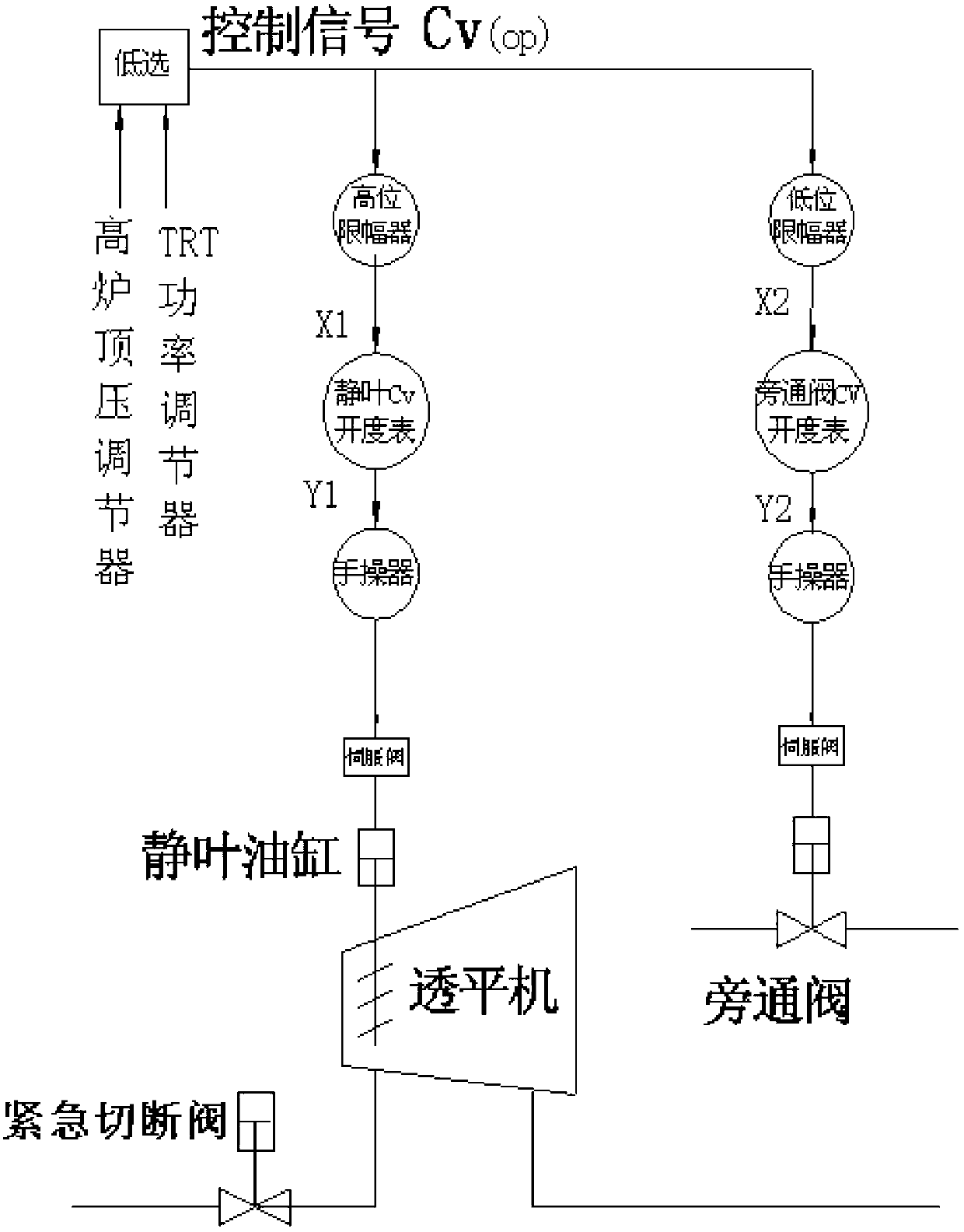

[0032] The invention is mainly realized by obtaining the standard valve characteristic curve parameters of the main control valve, quantifying the conversion of valve flow capacity, split range and feed-forward control.

[0033] The present invention collects key instrument parameters, performs calculation and comparison, obtains the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com