Mixed gas calorific value stabilization control method

A stable control method and mixed gas technology, applied in controllers with specific characteristics, combustion methods, controlled combustion, etc., can solve problems affecting the heating quality of the billet in the heating furnace, and achieve resource saving, accurate calorific value, and benefit improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

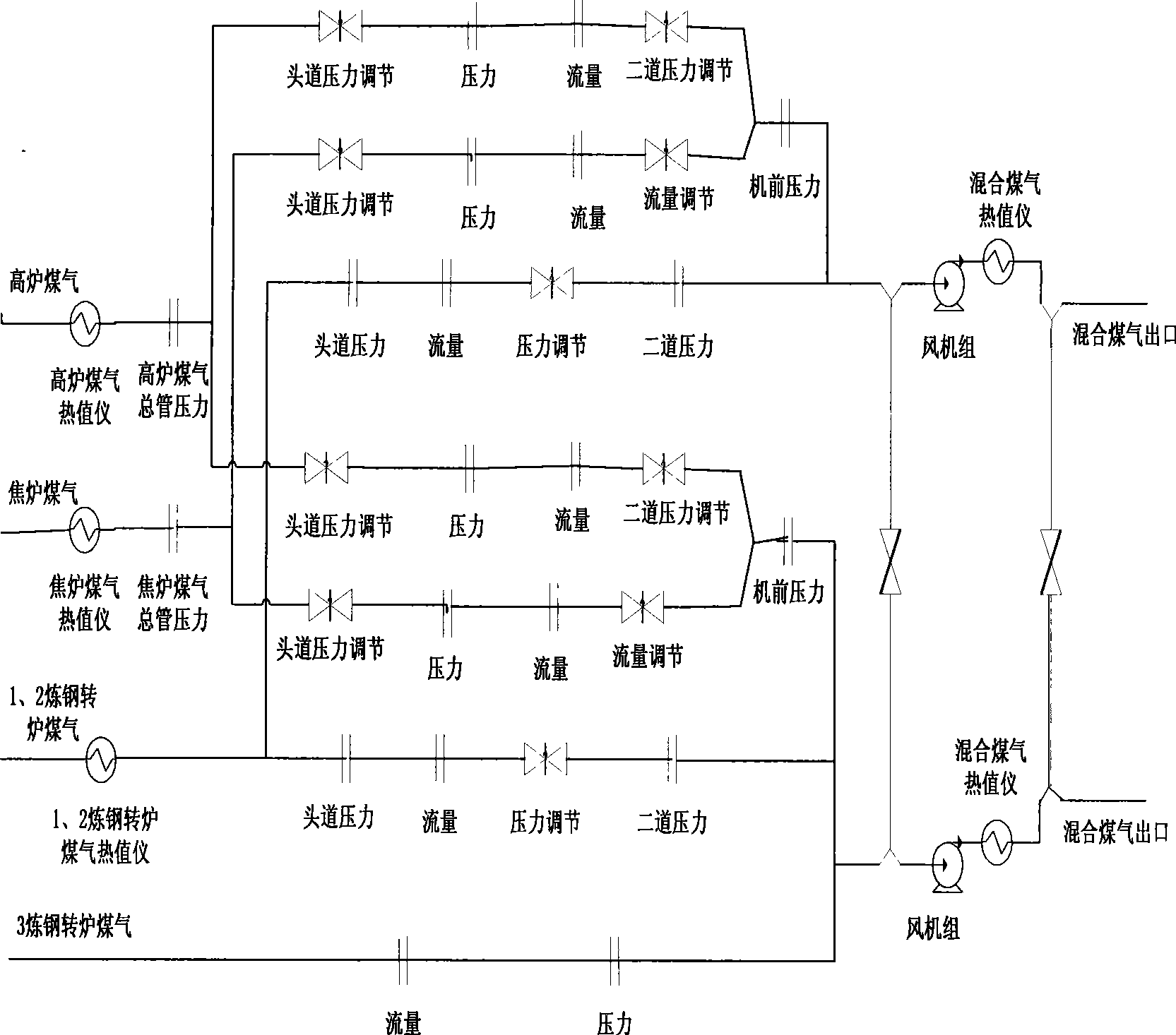

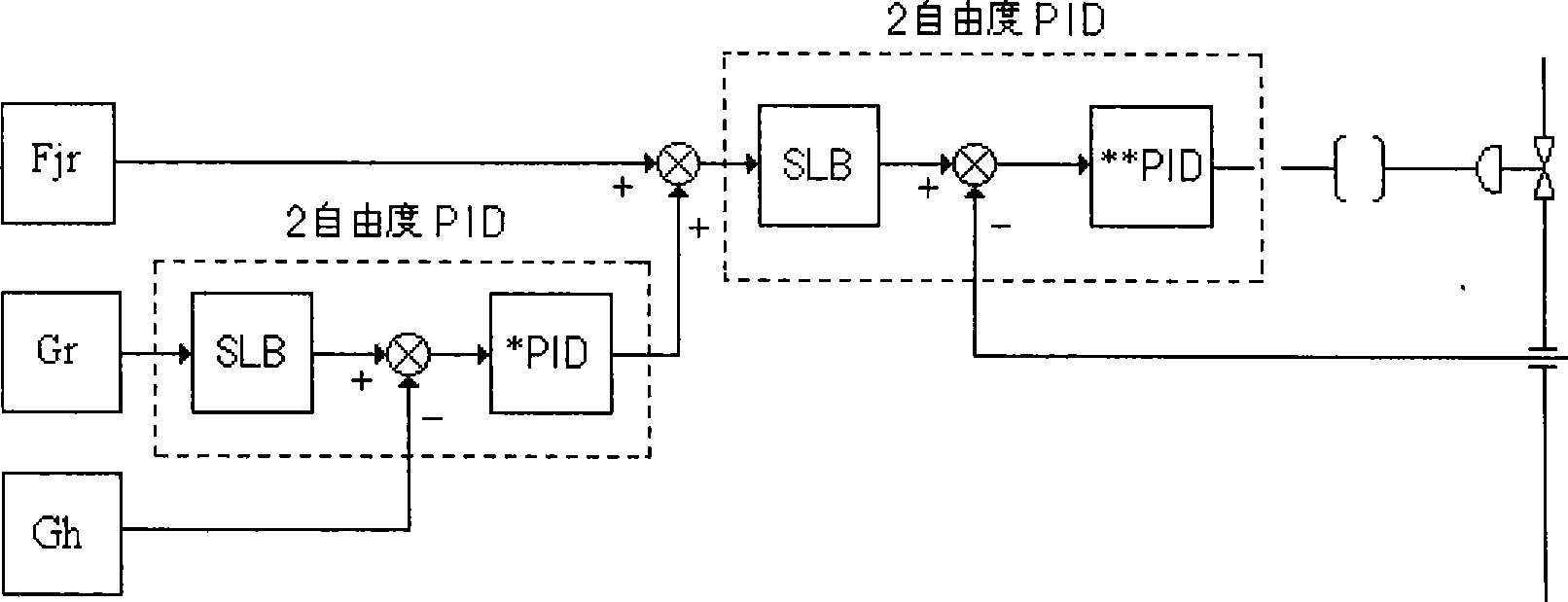

[0011] In order to timely and effectively control and adjust the calorific value and pressure of the mixed gas, the method of the present invention uses a calorific value meter to perform feedforward adjustment and feedback compensation adjustment control on the calorific value of the mixed gas.

[0012] A stable control method for the calorific value of mixed gas, characterized in that: the measured calorific value of blast furnace, coke oven, converter gas, the set value of the calorific value of mixed gas and various gas input quantities are used as the input of the feedforward regulation control loop Parameters, the required coke oven gas flow rate is calculated by the energy balance formula; after feed-forward adjustment, when the calorific value of the mixed gas still does not reach the set value, the measured calorific value of the mixed gas and the calorific value of the mixed gas are set The difference between the fixed values is used as the input parameter of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com