Nitrogen closed-loop control method and system

A closed-loop control, nitrogen technology, applied in various fluid ratio control, manufacturing tools, reinforcement of conductive patterns, etc., can solve the problems of high production cost, large nitrogen consumption, poor reliability of oxygen concentration, etc., to achieve environmental stability and saving. The effect of consumption and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

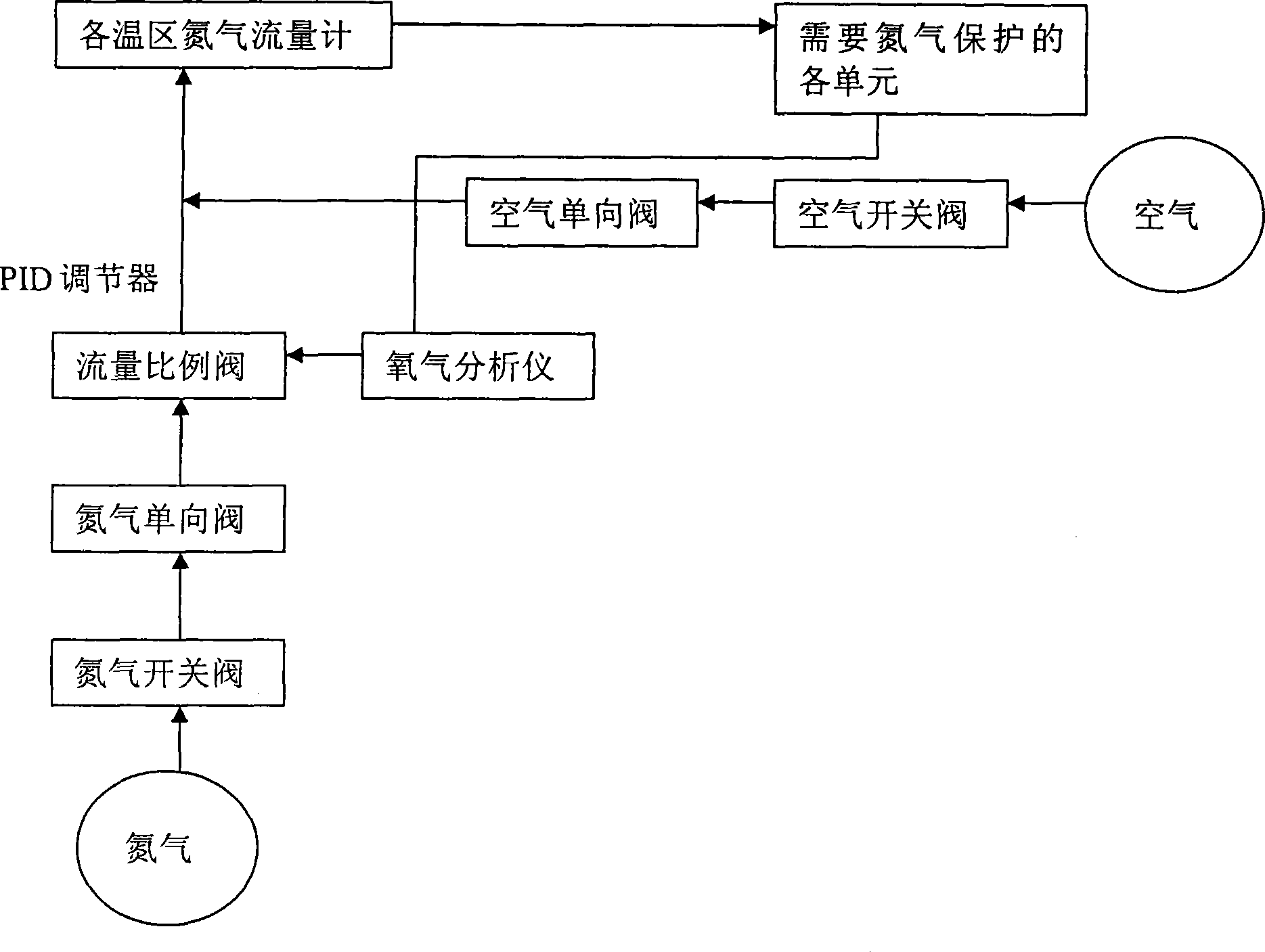

[0015] Attached below figure 1 And embodiment the present invention is described further.

[0016] The nitrogen closed-loop control method of the present invention, its system is as figure 1 As shown, it includes the following steps:

[0017] (a). When the reflow soldering furnace is just started, the flow proportional valve will automatically adjust to the maximum flow rate, and the nitrogen gas will enter the units in the reflow soldering furnace that need nitrogen protection at the maximum flow rate, and quickly reach the set oxygen concentration value;

[0018] (b). After each unit in the reflow soldering furnace that needs nitrogen protection reaches the ideal oxygen concentration value, the flow proportional valve will automatically reduce the nitrogen flow rate to maintain the set oxygen concentration value;

[0019] (c). When the reflow soldering furnace is in normal operation, the oxygen analyzer samples the oxygen concentration in the reflow area in the furnace in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com