Method for predicting and controlling steam temperatures of boilers on basis of state observation model

A technology of predictive control and state observation, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of long stable period, achieve the effect of improving object characteristics and reducing field test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

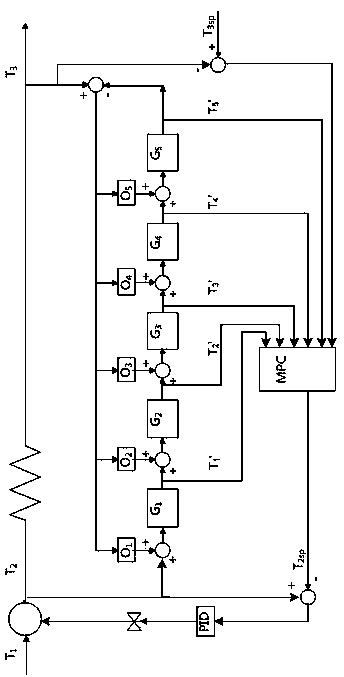

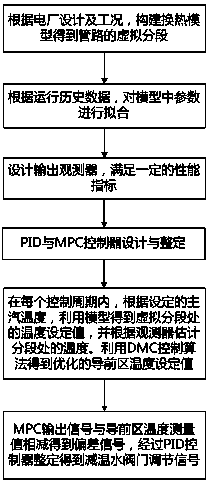

[0017] Embodiment: A boiler steam temperature predictive control method based on a state observation model, comprising:

[0018] Step 1. Based on the principle of natural segmentation or virtual segmentation, the entire heat exchanger is replaced by a multi-section centralized parameter link for processing, and the medium outlet parameters of each section are used as representative parameters of the centralized link, or design data or operation history data are exchanged Heater enthalpy temperature channel for mathematical modeling.

[0019] The steam temperature change of the boiler is carried out in heat exchange equipment such as a typical single-phase working medium heat exchanger. The heat exchanger usually has a long pipeline, and from the perspective of full utilization of heat and optimal design of the process flow, there are many A mixed layout pattern forms a natural boundary, such as the low-temperature horizontal section, low-temperature vertical section, and high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com