Single-channel servo control module

A servo control, single-channel technology, applied in the direction of servo motor components, engine components, fluid pressure actuators, etc., can solve the problems of no online monitoring function, lack of configuration software cooperation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

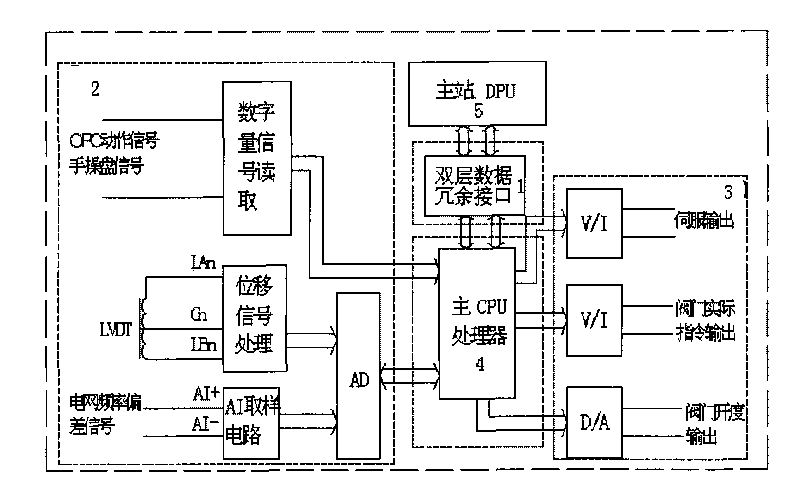

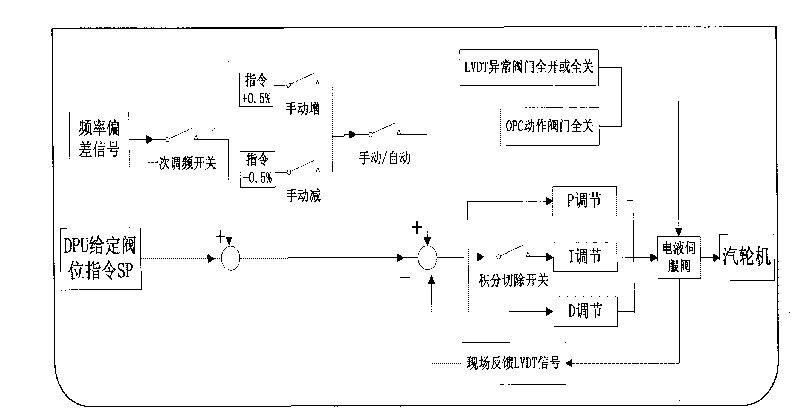

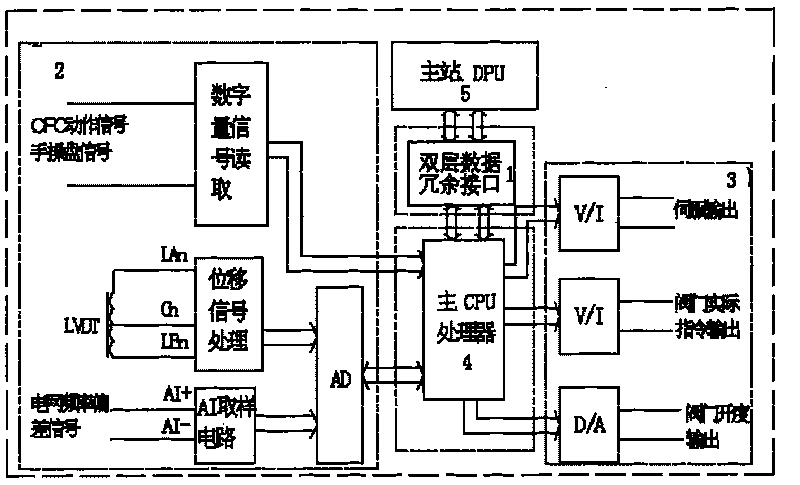

[0026] A kind of single channel servo control module of the present invention, see figure 1 : It includes double-layer data redundancy interface 1, signal acquisition and detection interface 2, servo drive interface 3 and module main CPU processor 4, double-layer data redundancy interface 1 completes master station DPU 5 and module main CPU processor 4 The data exchange between them; the signal acquisition and detection interface 2 collects various feedback or control signals on site and sends them to the main CPU processor 4 of the module for calculation; the main CPU processor 4 of the module receives After the information detected by the data and signal acquisition and detection interface 2 is processed (P, PI, etc. adjusted), it acts on the electro-hydraulic servo valve through the servo drive interface 3 .

[0027] The present invention is specified as follows:

[0028] 1. Adopt dual-bus parallel working mode to realize redundant data transmission.

[0029] Since this m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com