A winch hydraulic system that controls the guide cable through stepless speed regulation and constant tension

A technology of stepless speed regulation and hydraulic system, which is applied to clockwork mechanisms, fluid pressure actuators, servo motors, etc., can solve problems such as power loss, and achieve the effects of reducing failure rates, improving efficiency, and reducing volume space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

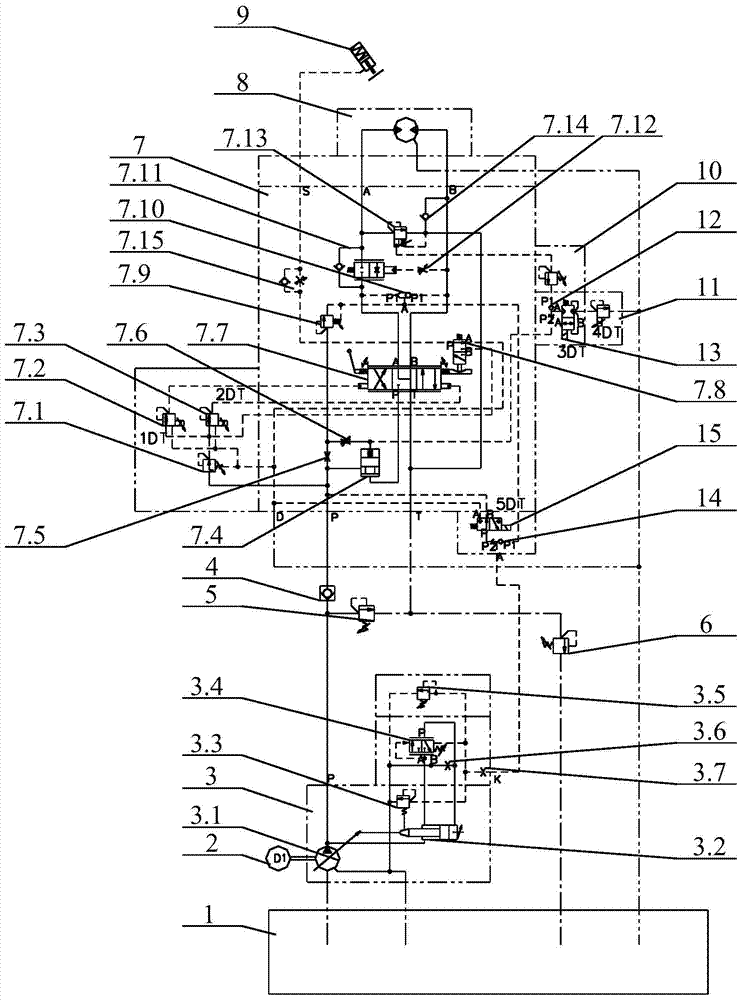

[0035] see figure 1 As shown, the winch hydraulic system in the embodiment of the present invention controls the guide cable through stepless speed regulation and constant tension, including a fuel tank 1, a motor 2, a variable hydraulic pump group 3, a check valve 4, a high pressure relief valve 5, and a back pressure relief valve. Flow valve 6, motor operation valve group 7, winch motor 8, brake cylinder 9, plate relief valve 10, proportional relief valve 11, first threaded cartridge shuttle valve 12, second threaded cartridge shuttle valve 14, Two-position two-way normally closed ball valve 13 and two-position three-way electromagnetic ball valve 15.

[0036]The motor operation valve group 7 controls the hoisting operation of the winch, including a pressure reducing valve 7.1, a first electromagnetic proportional pressure reducing valve 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com