Anti-sway control of a crane under operator's command

A manipulator, anti-sway technology, applied in the direction of cranes, cranes, load suspension components, etc. of trolleys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

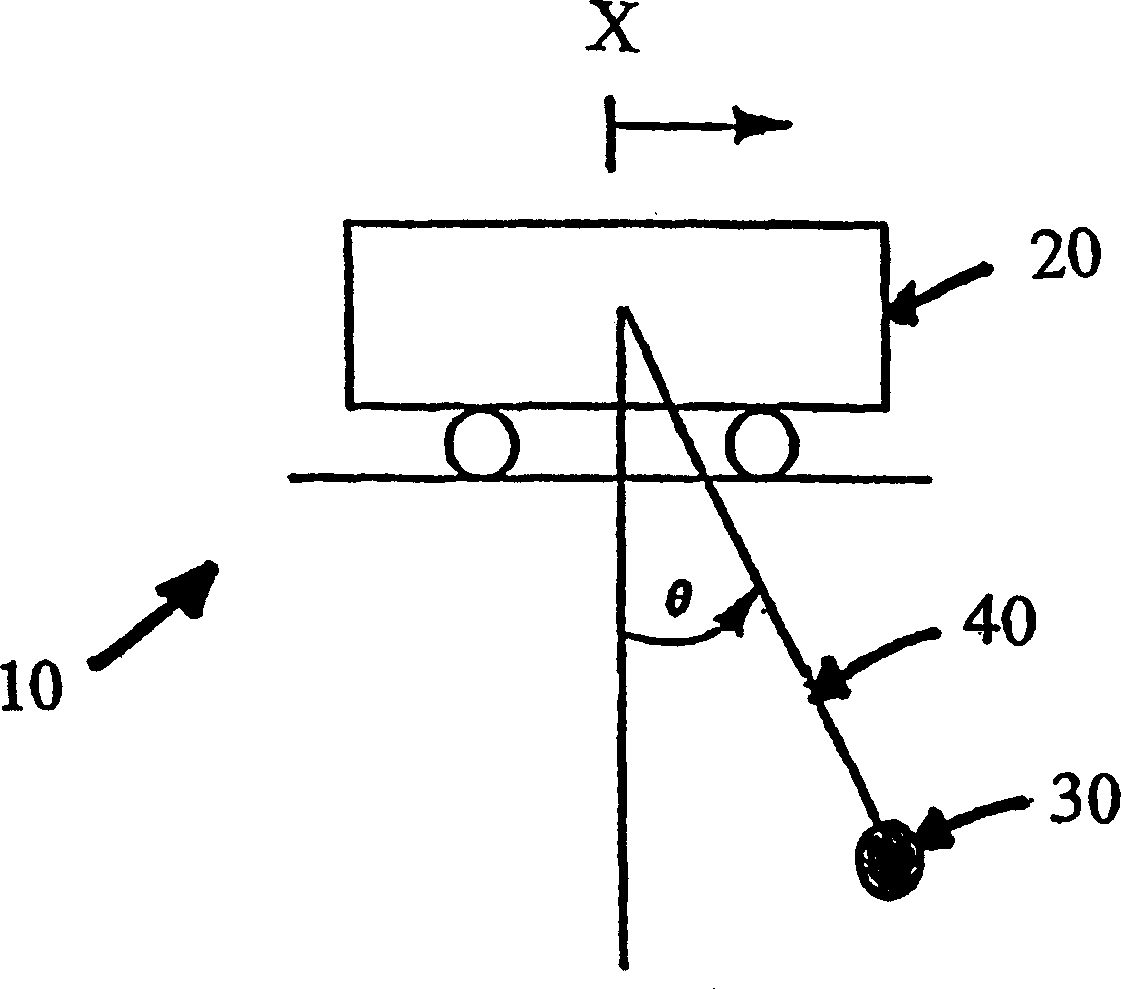

[0031] refer to figure 1 , shows a model of the crane system 10 . Crane system 10 includes a tackle 20 having a hoist (not shown) to adjustably suspend payload 30 by rope 40 . The swing angle θ is generated between the position of the rope 40 at rest and the position of the rope 40 during the swing oscillation. The differential equation describing the development of the sway angle θ of the payload 30 over time is:

[0032] l ( t ) θ . . ( t ) + 2 l . ( t ) θ . ( t ) + g sin θ ( t ) = x . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com