Force excitation protection circuit suitable for direct-current injection type rotor grounding protection measurement loop

A technology of rotor grounding and protection measurement, which is applied in the direction of emergency protection circuit devices and electrical components, which can solve the problems of protection refusal, damage of components in the measurement circuit, and large current flow, so as to prevent protection refusal and increase fault tolerance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

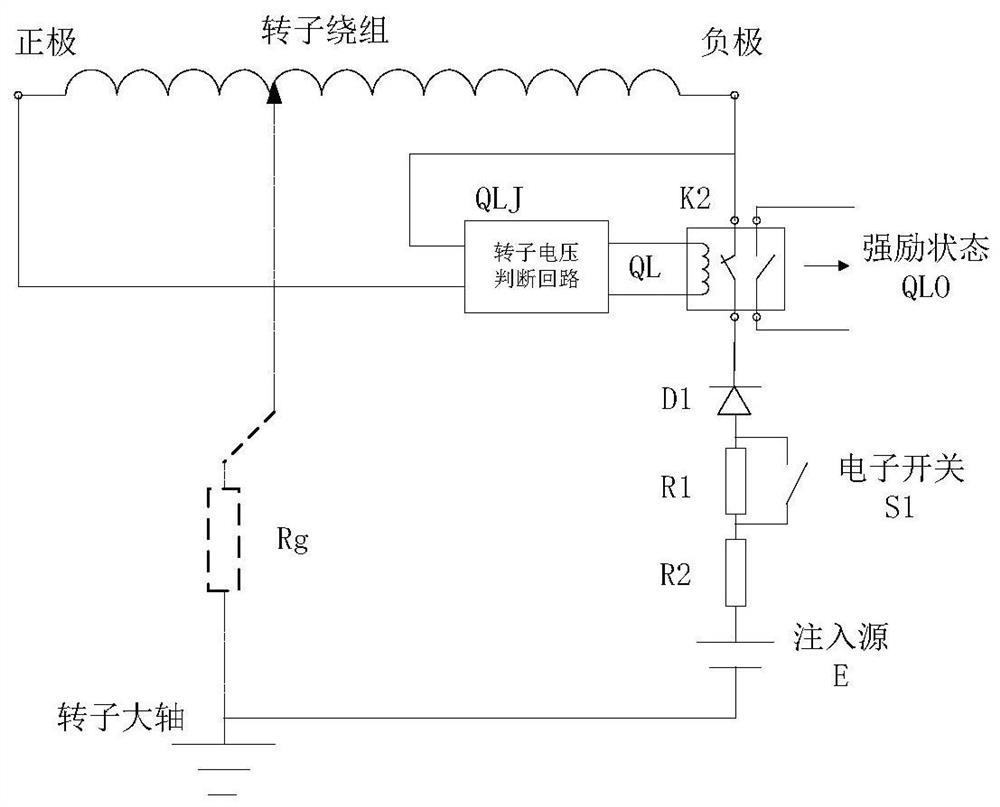

[0035] This embodiment introduces the strong excitation protection circuit suitable for the measurement circuit of the DC injection rotor grounding protection, refer to image 3 As shown, the forced excitation circuit includes a relay K2 and a rotor voltage detection circuit QLJ.

[0036] The rotor voltage detection circuit QLJ includes resistor R3, resistor R4, and voltage regulator tube D2. The positive pole of the rotor is connected to one end of resistor R3, the other end of resistor R3 is connected to one end of resistor R4 and the negative pole of voltage regulator tube D2, and the negative pole of the rotor is negative. The input is connected to the other end of the resistor R4, and the anode of the regulator tube D2 outputs a strong excitation signal QL.

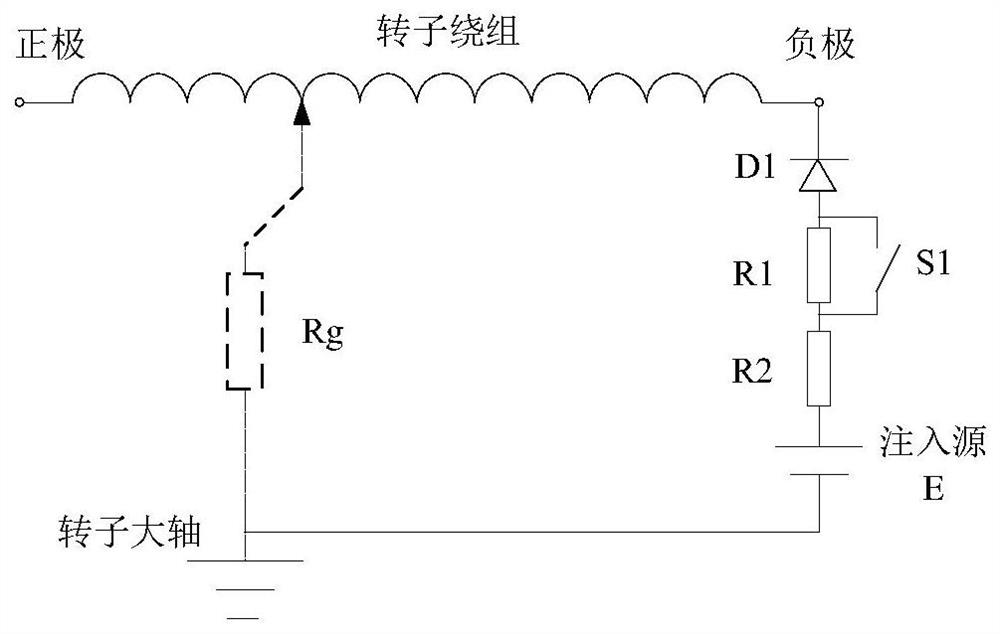

[0037] The large shaft of the rotor is connected to the negative pole of the common terminal of the DC injection power supply E, the positive pole of the DC injection power supply E is connected to one end of the res...

Embodiment 2

[0041] On the basis of embodiment 1, this embodiment refers to Figure 4 As shown, the positive and negative poles of the rotor are connected to the rotor voltage judgment circuit QLJ through the rectification circuit ZL. At this time, regardless of whether the positive and negative poles of the rotor are reversed, the output voltage is positive, and the positive and negative polarities of the strong excitation protection circuit are added. fault tolerance.

Embodiment 3

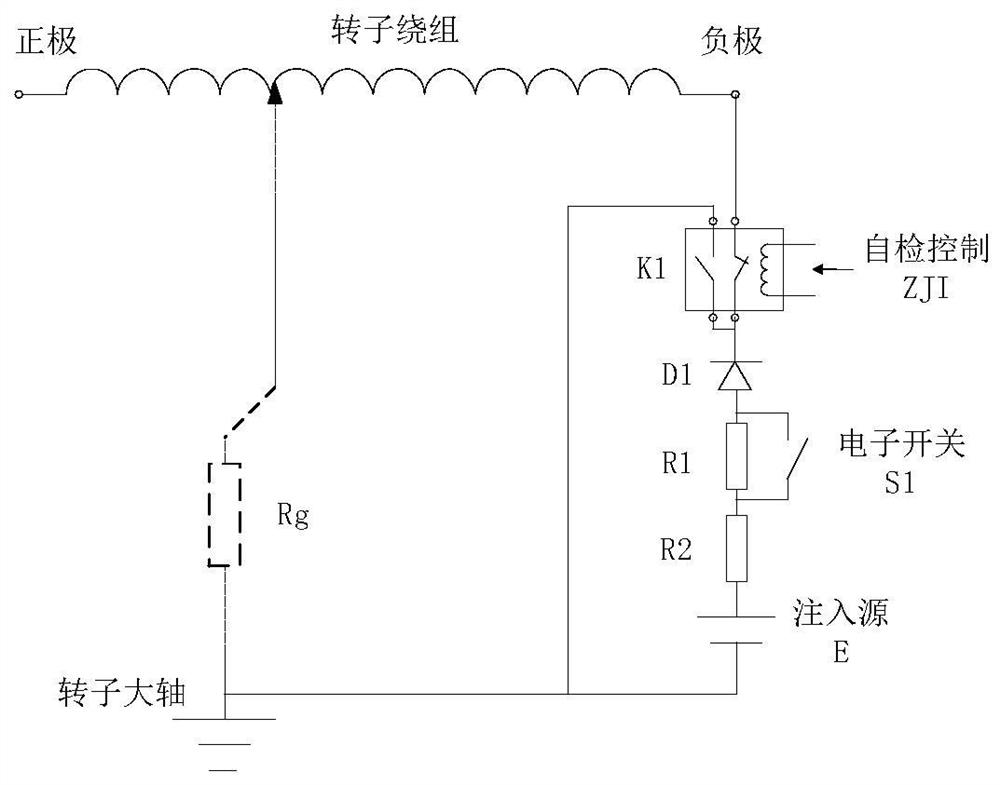

[0043] In order to realize the self-inspection of the measurement circuit, this embodiment introduces a self-inspection circuit suitable for the measurement circuit of the DC injection rotor grounding protection, refer to figure 2 As shown, the self-test circuit includes a relay K1, and the relay K1 includes a normally closed contact and a normally open contact; the first end of the normally closed contact of K1 is connected to the negative pole of the rotor, and the second end is injected with DC through D1, R1, R2. The source is connected to the main shaft of the rotor; the first end of the normally open contact of K1 is connected to the main shaft of the rotor, and the second end is connected to the second end of the normally closed contact of K1; the coil of K1 is connected in a self-test control loop.

[0044] The conduction of the self-test control circuit will make the K1 coil conduct, so that the K1 normally closed contact is disconnected, the original measurement circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com