Material bag pouring structure of belt conveyor

A technology for belt conveyors and materials, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as high center of gravity, hidden safety hazards, etc., achieve simple and clear structure, avoid flattening and crushing, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

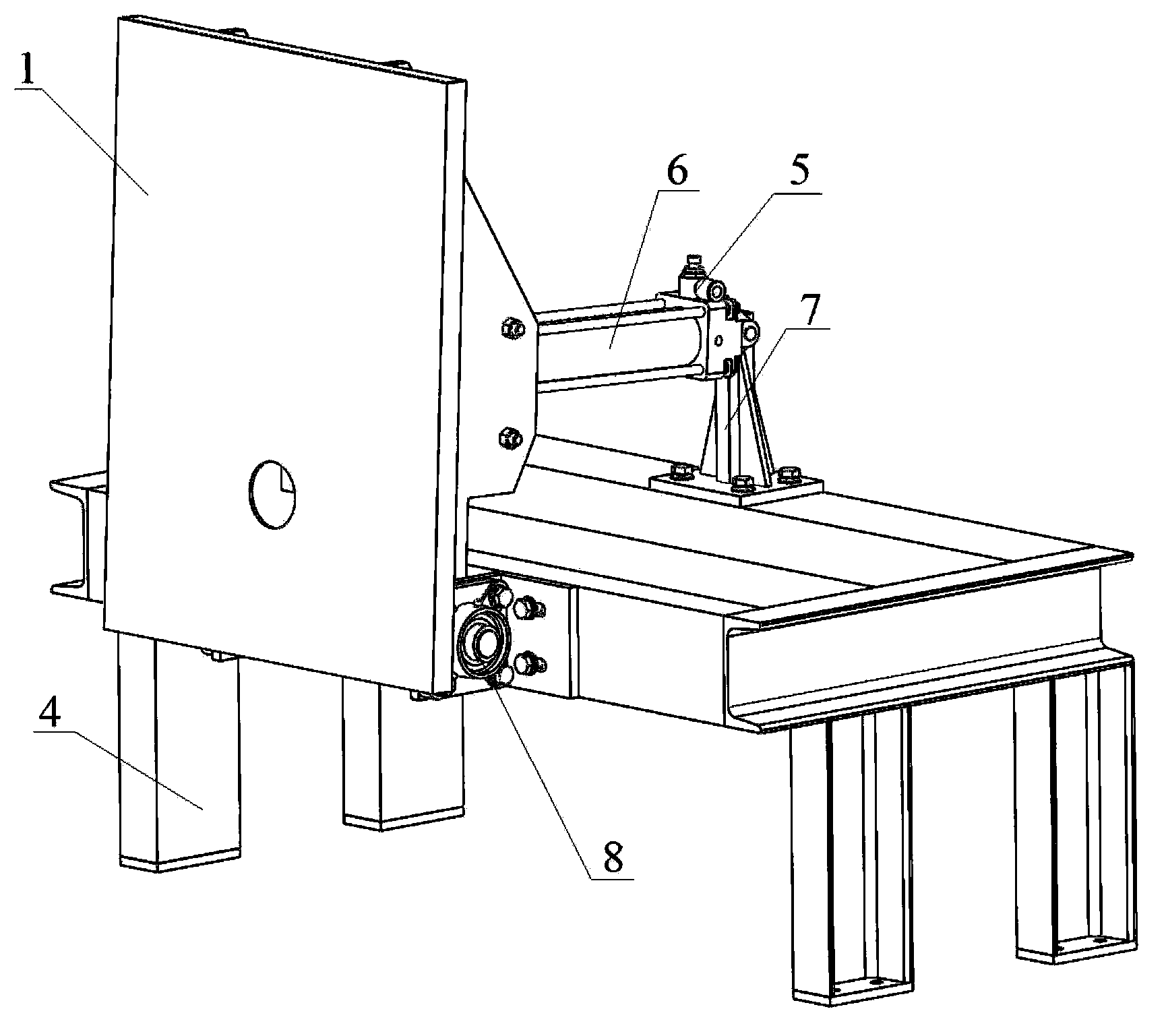

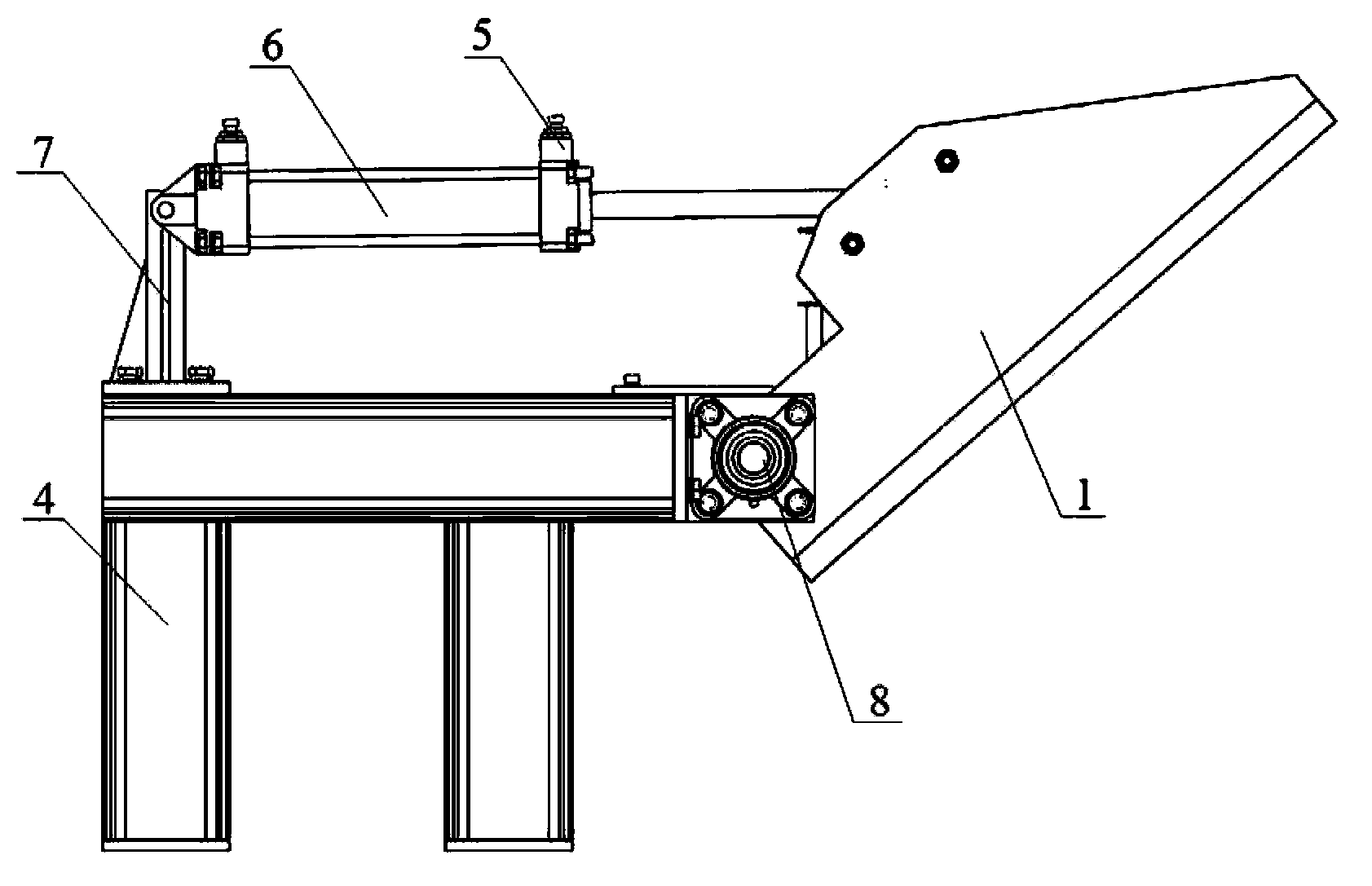

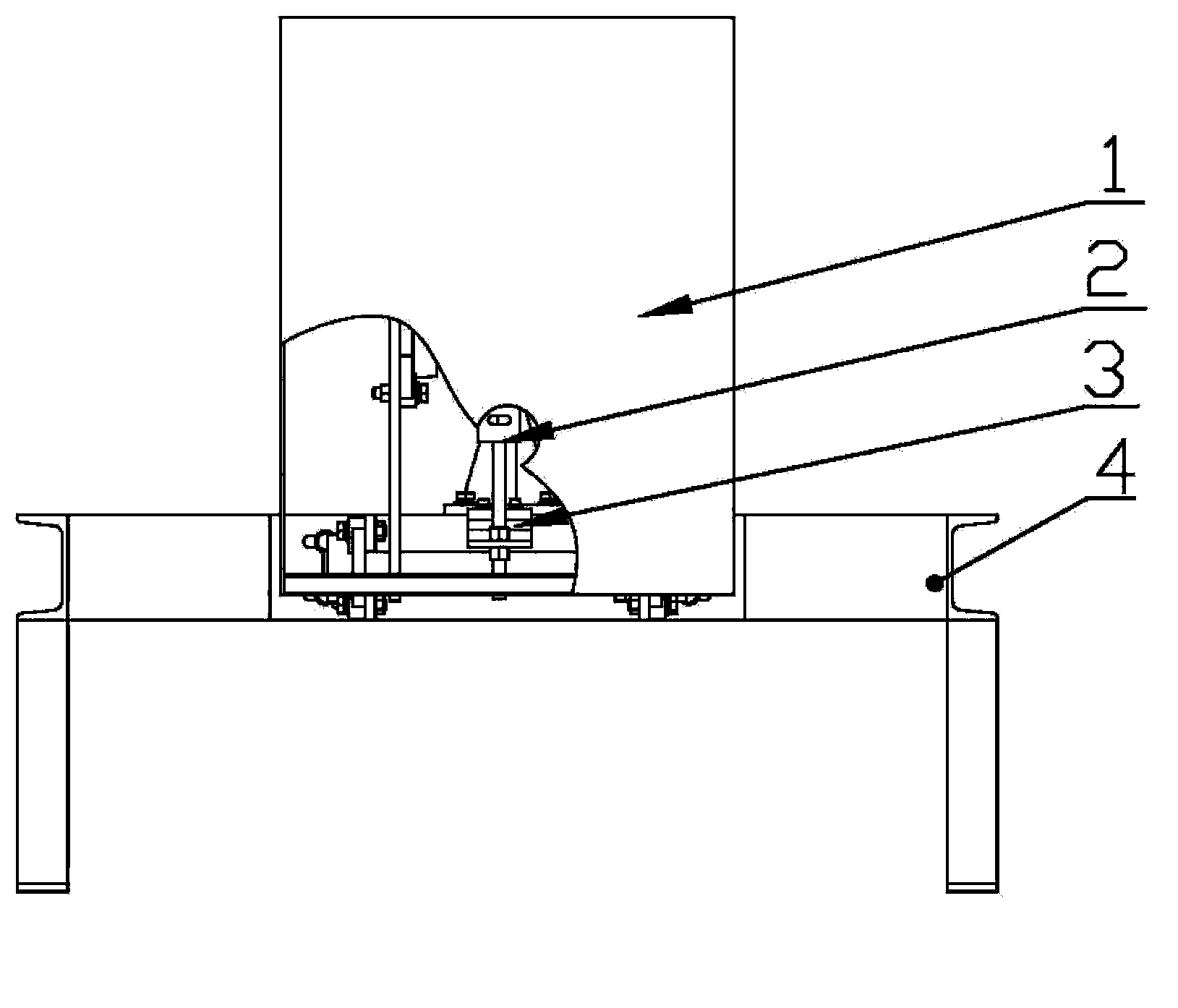

[0028] A belt conveyor material rewinding structure, such as Figure 1 to Figure 5 As shown, the structure includes a support 4, a control device, a push plate device and an induction device. The control device includes a cylinder 6 and a solenoid valve. The cylinder 6 is fixed on the rear side of the support 4. The solenoid valve is connected to the cylinder 6. The push plate 1 device includes Push pedal 1 and push pedal connecting rod 9, the bottom end of push pedal 1 rear side is rotatably connected with the front end of support 4 through belt square seat bearing 8, the middle part of push pedal 1 rear side is connected with cylinder 6 through push pedal connecting rod 9, The middle and lower part of the push plate 1 is provided with a hole. The sensing device includes a photoelectric sensor, an electric eye mounting frame 2 and a slow photoelectric fixing frame 3. Located at the same height as the hole on the push plate 1, the photoelectric sensor is connected to the solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com