Y-shaped spring locator for hydraulic end of fracturing pump

A locator and fracturing pump technology, applied to pump components, variable displacement pump components, machines/engines, etc., can solve problems such as fatigue crack damage, stress concentration, etc., to reduce stress concentration parts and eliminate the existence of grooves , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

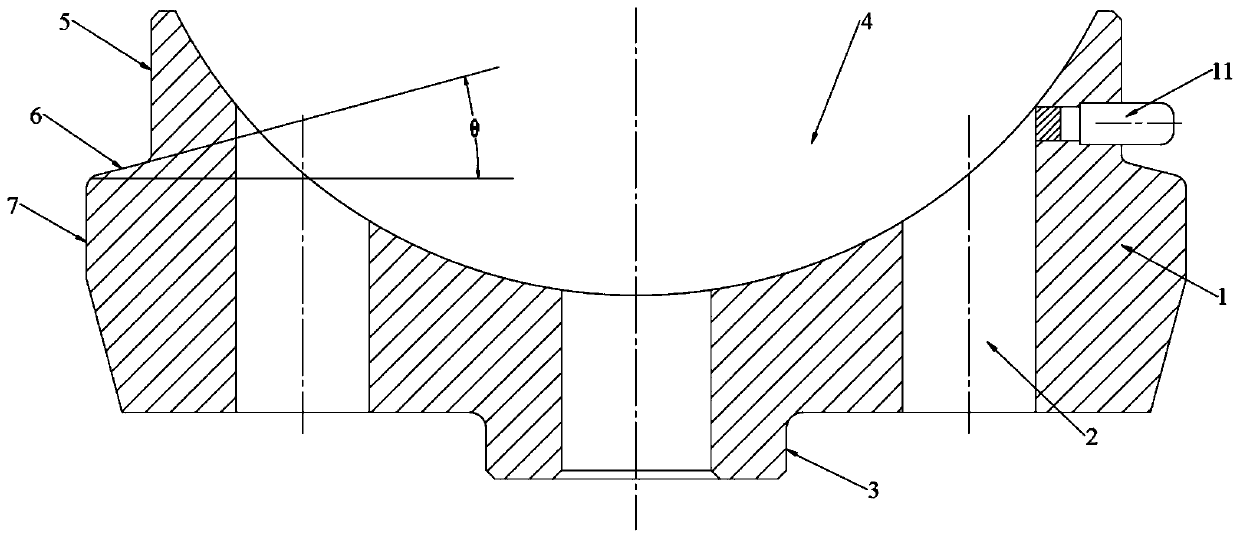

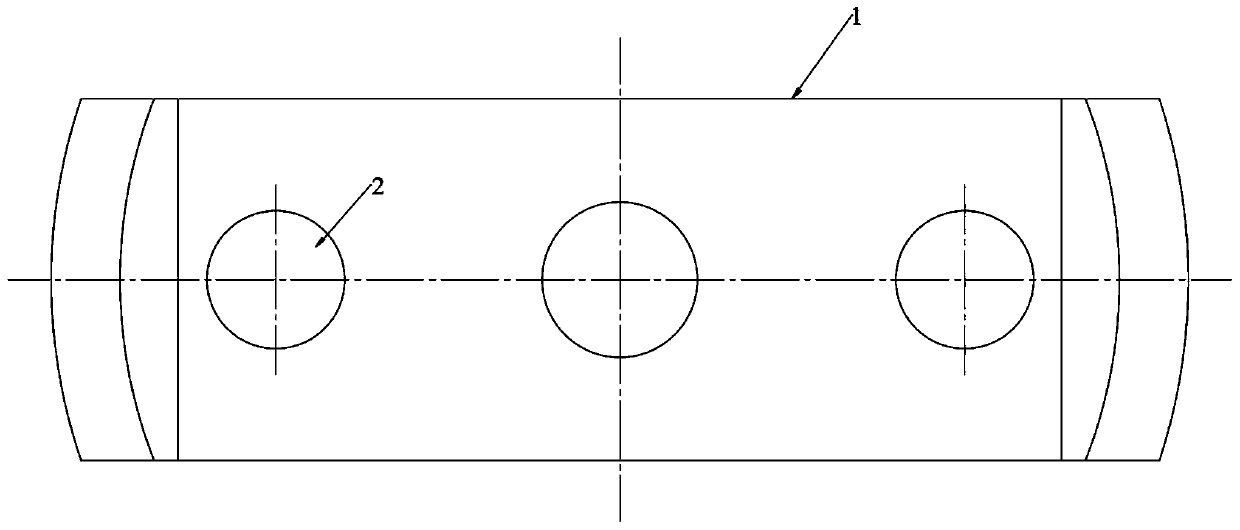

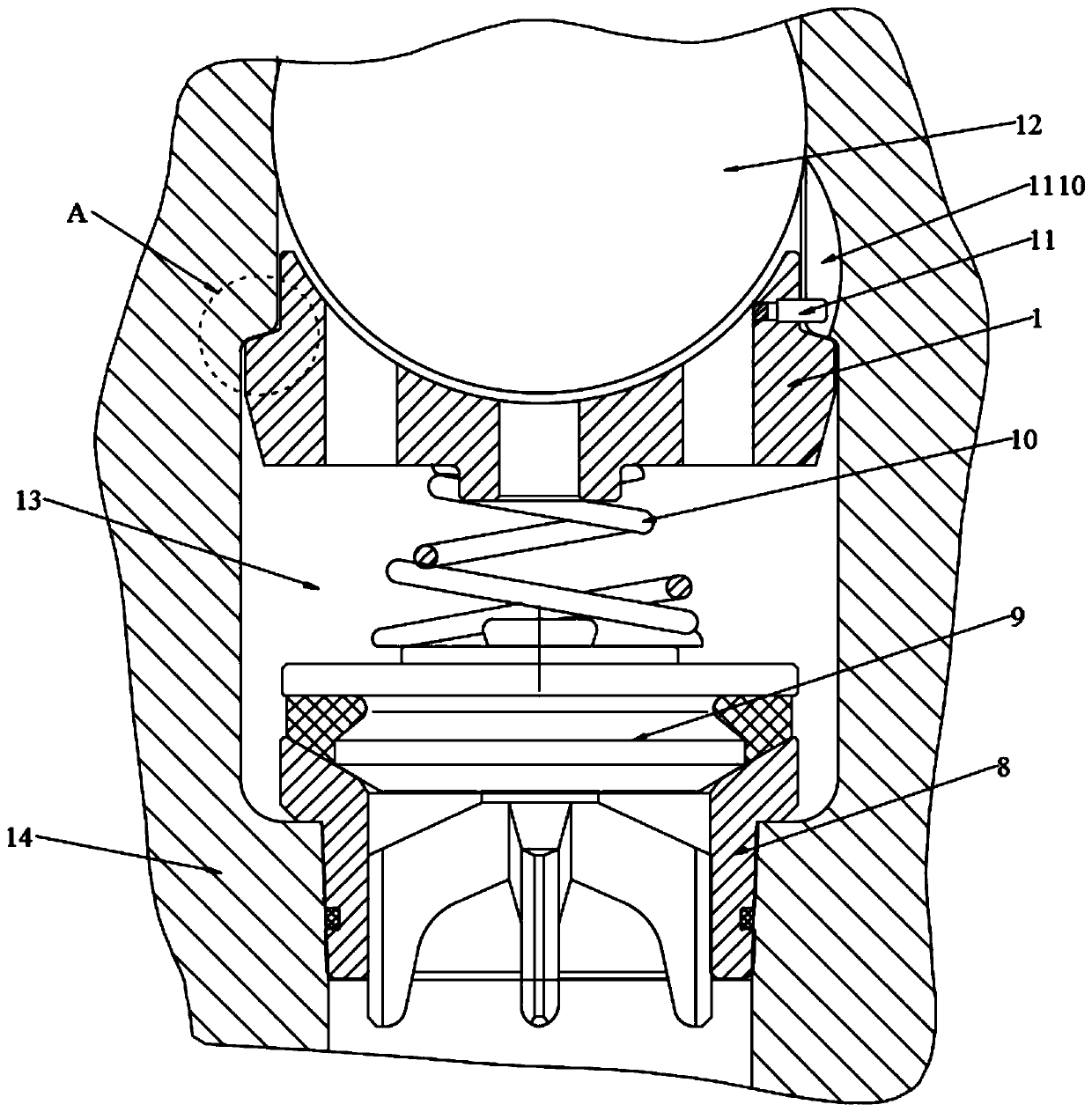

[0032] The Y-shaped spring locator for the hydraulic end of the fracturing pump of the present invention includes a valve box body 14, a suction chamber 13 is opened in the valve box body 14, a suction valve body 9 is arranged at the lower end of the suction chamber 13, and the suction valve body 9 is externally arranged. There is an adsorption valve seat, the upper end of the suction valve body 9 is provided with a suction spring 10, and the upper end of the suction spring 10 is provided with a locator body 1; the lower end of the locator body 1 is provided with a circular boss 3 sleeved in the suction spring 10, positioning The upper end of the device body 1 is recessed downward to form a positioning groove 4 of an arc surface, and the left and right outer walls of the locator body 1 include an upper section 5 and a lower section 7 below the upper section 5, the outer diameter of the upper section 5 is smaller than the outer diameter of the lower section 7, The upper section ...

Embodiment 2

[0035] Present embodiment is further optimized on the basis of embodiment 1 as follows: the taper angle θ of conical surface 6 is 15-75 °, for example: 15 °, 30 °, 40 °, 45 °, 60 °, 70 ° and 75° etc.

[0036] After adopting the above-mentioned technical scheme, the taper angle of the conical surface 6 is 15-75°. According to the matching valve parts of the valve box and the structural characteristics of the valve box body 14 itself, this interval is selected in conjunction with the taper angle to ensure that the positioner body 1 Stability after installation, and the force is evenly distributed on the cone surface 6, less fatigue damage due to stress concentration.

[0037] The material performance requirements for the positioner body have the following requirements:

[0038]

Embodiment 3

[0040] This embodiment is further optimized on the basis of Embodiment 1 as follows: the upper section 5 on one side of the positioner body 1 is provided with an anti-rotation pin 11 along the horizontal direction, and the inner wall of the upper end of the suction chamber 13 is provided with an anti-rotation pin 11. The anti-rotation limiting eccentric groove 1110 is adapted, and the lower end of the anti-rotation limiting eccentric groove 1110 runs through the limiting structure. The width of the anti-rotation limiting eccentric groove 1110 is greater than that of the anti-rotation pin 112-5mm.

[0041] After adopting the above technical solution, an anti-rotation pin 11 is provided on the upper section 5 of one side of the positioner body 1. After installation, the anti-rotation pin 11 enters the anti-rotation limiting eccentric groove 1110, effectively preventing the positioner from rotating in the horizontal direction; The installation process is that the locator body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com