Large-span equipment frame foundation leveling and assembling construction device and method

A construction device and construction method technology, applied in the field of large-span equipment frame foundation leveling and assembling construction device, can solve the problems of affecting the construction progress, increasing labor costs, low precision, etc., to reduce the consumption of materials, shorten the construction period, and ensure the level of The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

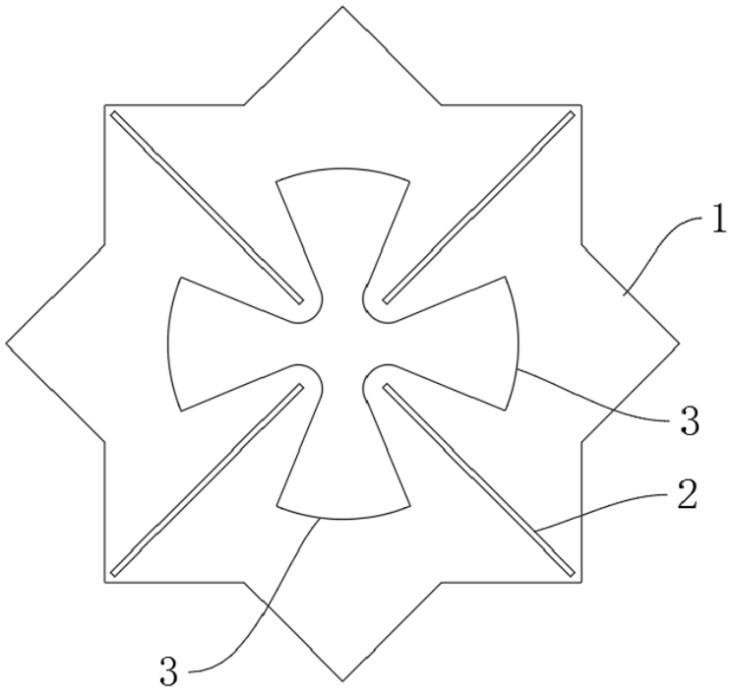

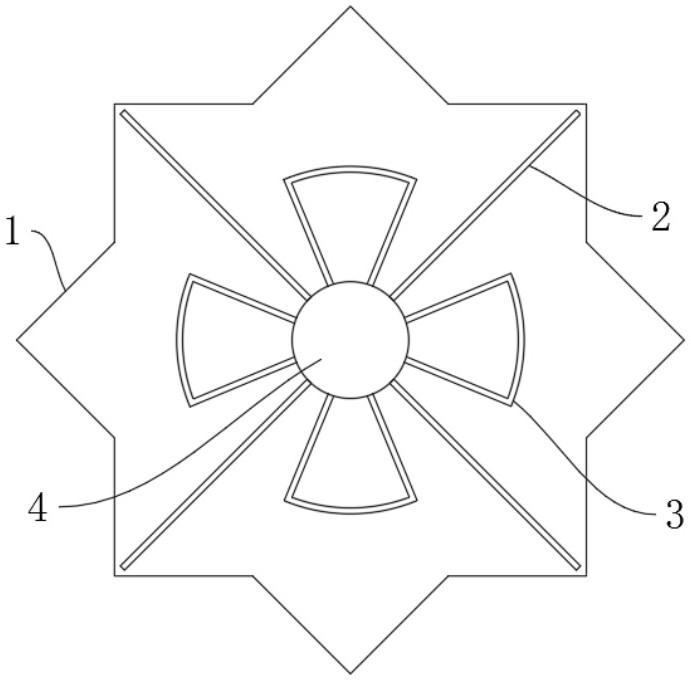

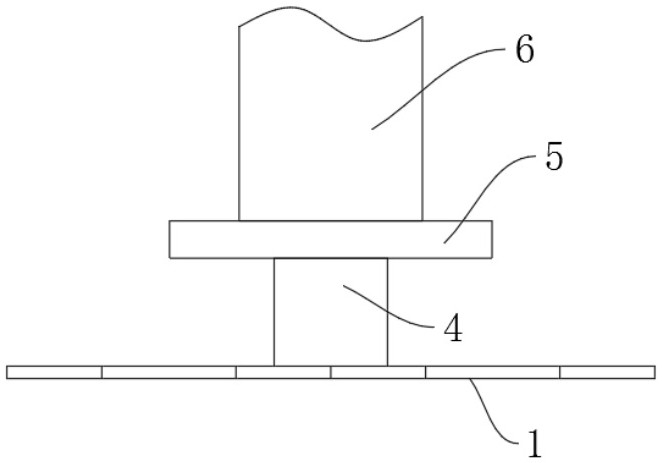

[0031] refer to Figure 1-3 , the large-span equipment frame foundation leveling assembly construction device, including: the anchor plate positioner 1, which is arranged in a bent octagonal shape, the auxiliary cross line 2 is arranged on the anchor plate positioner 1; the hole 3 is arranged on the anchor plate positioning seat 1 ; The square tube connecting frame 4 is detachably connected to the hole 3, and the specific square tube connecting frame 4 is welded at the hole 3 of the anchor plate locator 1 for connecting and installing the equipment frame, that is, the square tube connecting frame 4 A square tube corner plate 5 is fixedly connected to the top, and a square pipe fitting 6 is connected to the square tube corner plate 5 .

[0032] A backing plate is provided between the square tube angle plate 5 and the hole 3, which can improve the connection stability of the square tube angle plate 5, and the supporting effect of the opposite tube angle plate 5 is good, and the ...

Embodiment 2

[0034] refer to Figure 1-3 , the construction method for leveling and assembling the foundation of the large-span equipment frame, including the construction device for leveling and assembling the foundation of the large-span equipment frame, specifically comprising: the anchor plate locator 1, which is arranged in a bent octagonal shape, and the anchor plate locator 1 is provided with an auxiliary cross line 2; The hole 3 is set on the anchor plate positioning seat 1; the square tube connecting frame 4 is detachably connected to the hole 3, and the specific square tube connecting frame 4 is welded at the hole 3 of the anchor plate positioner 1 for Connecting and installing the equipment frame, that is, the square tube connecting frame 4 is fixedly connected with a square tube angle plate 5 , and the square tube angle plate 5 is connected with a square pipe fitting 6 .

[0035] A backing plate is provided between the square tube angle plate 5 and the hole 3, which can improve...

Embodiment 3

[0044] refer to Figure 1-3 , the construction method for leveling and assembling the foundation of the large-span equipment frame, including the construction device for leveling and assembling the foundation of the large-span equipment frame, specifically comprising: the anchor plate locator 1, which is arranged in a bent octagonal shape, and the anchor plate locator 1 is provided with an auxiliary cross line 2; The hole 3 is set on the anchor plate positioning seat 1; the square tube connecting frame 4 is detachably connected to the hole 3, and the specific square tube connecting frame 4 is welded at the hole 3 of the anchor plate positioner 1 for Connecting and installing the equipment frame, that is, the square tube connecting frame 4 is fixedly connected with a square tube angle plate 5 , and the square tube angle plate 5 is connected with a square pipe fitting 6 .

[0045] A backing plate is provided between the square tube angle plate 5 and the hole 3, which can improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com