Square silencer shield and connecting bracket welding tool

A technology for connecting brackets and welding tooling, applied in the field of tooling fixtures, can solve the problems of high symmetry and horizontal welding requirements of connecting brackets, waste of materials and resources, affecting welding efficiency, etc., so as to improve welding efficiency and quality and ensure horizontal accuracy. And the effect of symmetrical accuracy, improving welding accuracy and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

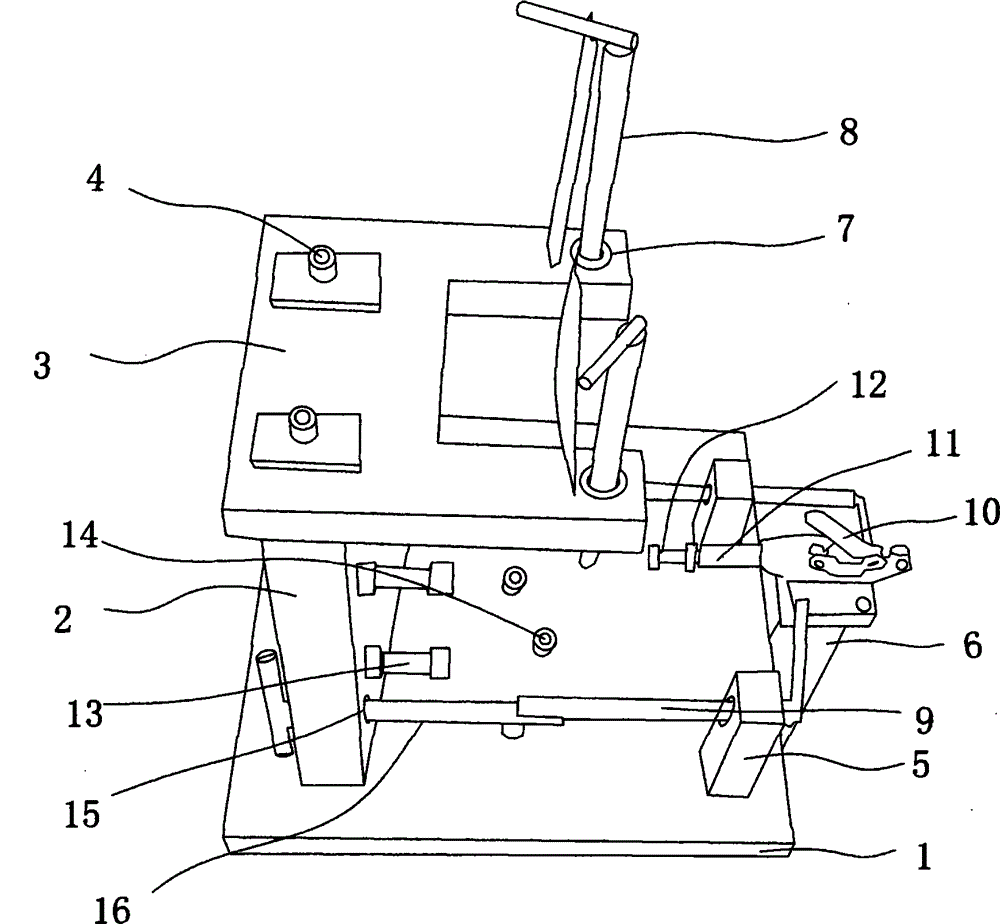

[0012] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0013] See figure 1 , a welding tool for a square muffler shield and a connecting bracket, including a base 1, a side support 2 arranged on one side of the base 1, and a top pressing on the top of the side support 2 Seat 3, the top pressure seat 3 is set in the same direction as the base 1, the top pressure seat 3 is set in an n-shaped configuration, and the n-shaped horizontal side of the top pressure seat 3 is connected to the side support by the fixing bolt 4 The seat 2 is fixedly connected, and a guide rail support 5 and a control support 6 are also provided on the base 1, and the guide rail support 5 is symmetrically arranged on the base 1 with the side support 2, and the control support 6 It is arranged on the side of the base 1 and is arranged on the same side as the guide rail support 5, and vertical positioning holes 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com