Assembling and using method of a glass positioning vacuum suction cup

A vacuum suction cup and suction cup technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inconsistent height around the glass, uneven glass plane, adsorption deformation of the glass plane, etc., to achieve ideal positioning and adsorption effect, easy to operate, The effect of saving rubber raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

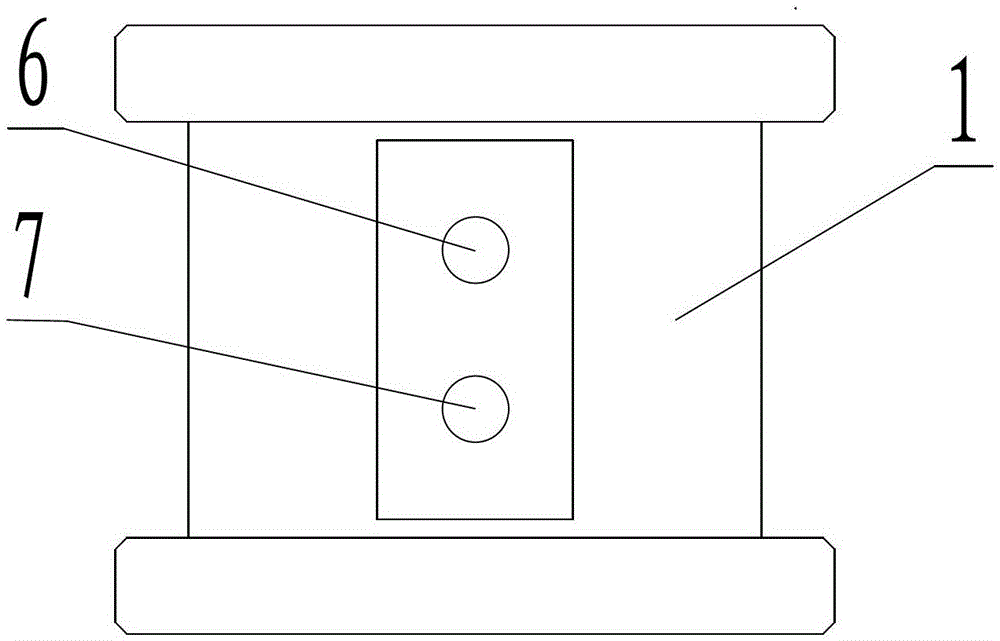

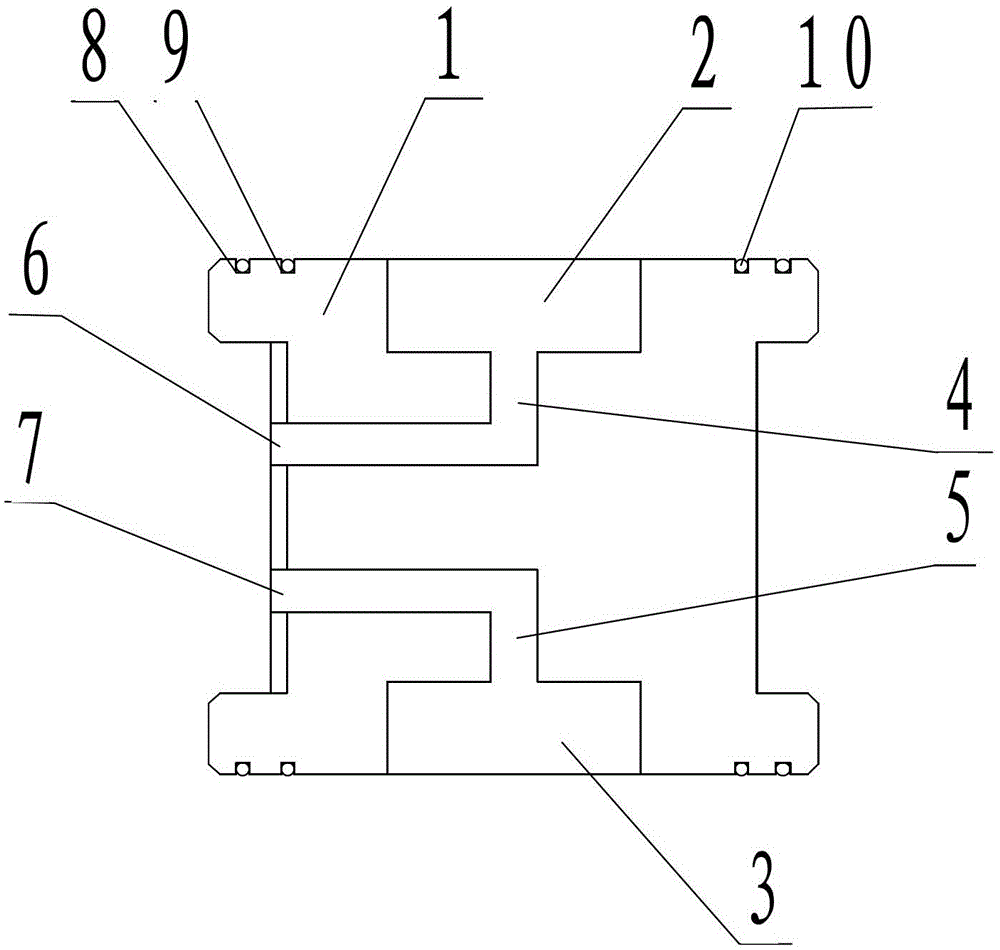

[0024] The sucker body 1 is cast into an I-shaped structure, the upper middle part of the sucker body 1 is processed into a cylindrical upper vacuum chamber 2, and the lower middle part is processed into a cylindrical lower vacuum chamber 3.

Embodiment 2

[0026] The center of the upper vacuum chamber 2 is drilled downwards to form a channel, and the outer wall of the suction cup body 1 is drilled at the corresponding position at the bottom of the channel to form a channel. The two channels communicate to form an inverted L-shaped upper vacuum channel 4. Install the upper joint 6; the center of the lower vacuum chamber 3 is drilled upwards to form a channel, the outer wall of the suction cup body 1 and the corresponding part of the top and bottom of the channel are drilled to form a channel, and the two channels are connected to form a reverse inverted L-shaped lower vacuum channel 5, and the lower vacuum channel 5 The lower joint 7 is installed at the port corresponding to the outer wall of the suction cup body 1; the upper joint 6 and the lower joint 7 are butted and installed with the vacuum pump through two vacuum tubes.

Embodiment 3

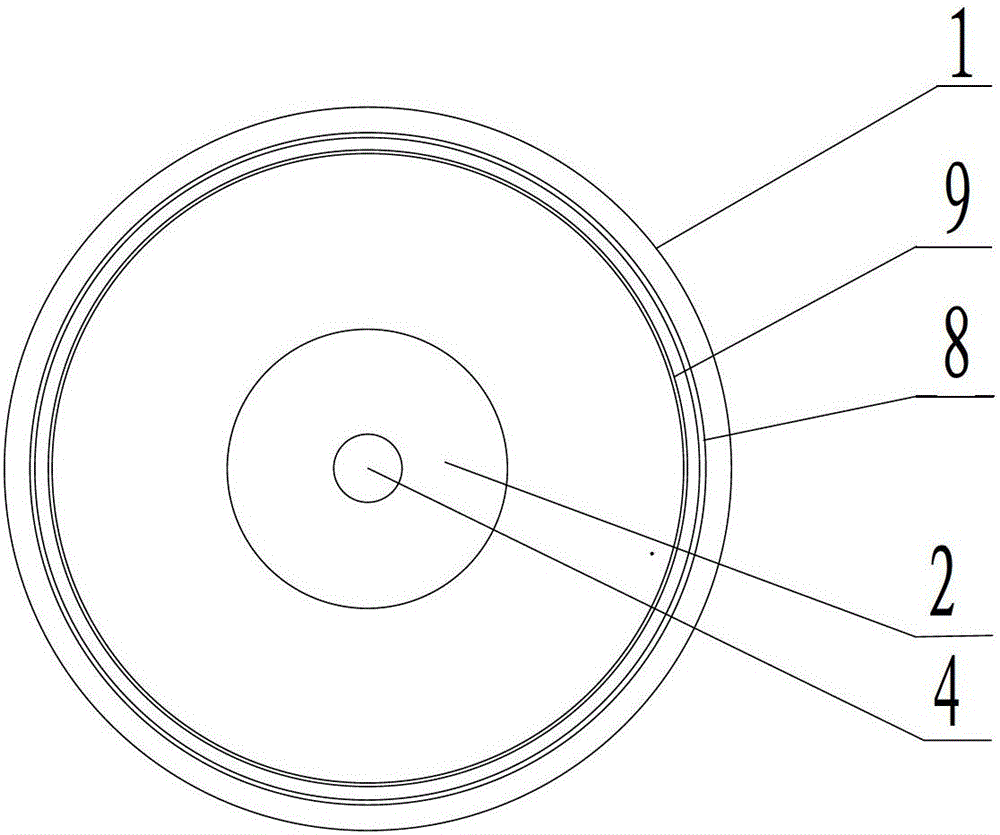

[0028] The upper plane and the lower plane of the suction cup body 1 respectively process the first annular sealing groove 8 and the second annular sealing groove 9. During processing, the second annular sealing groove 9 is located inside the first annular sealing groove 8, and the upper plane and the lower plane of the suction cup body 1 are processed at least 2 Ring ring seal groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com