Engineering-ceramic complex-frequency ultrasonic processing device

A technology of ultrasonic processing and engineering ceramics, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of poor processing quality and efficiency, limited processing shape, high cost, etc., achieve less moving parts and improve processing accuracy And processing efficiency, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

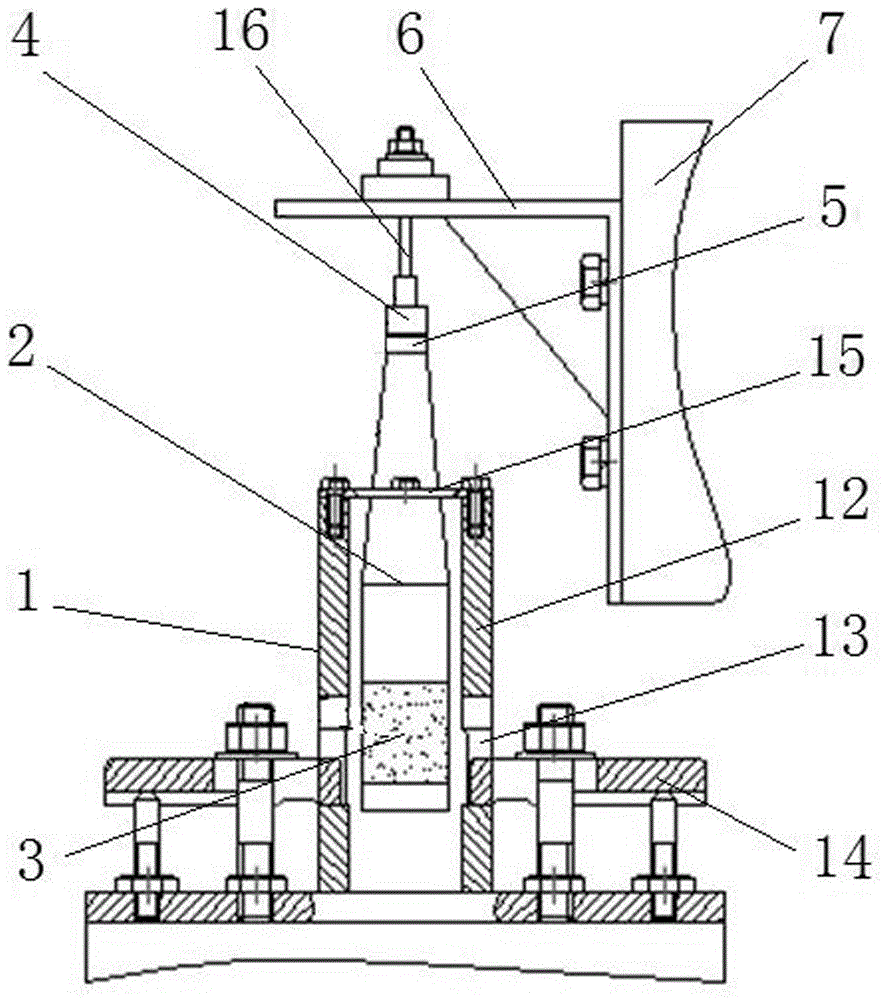

[0016] A multi-frequency ultrasonic processing device for engineering ceramics, comprising a bracket 1 arranged on a machine tool table, a horn 2 is arranged on the bracket 1, a transducer 3 connected to the horn 2 is arranged at the lower end of the horn 2, and the horn 2 The upper end of 2 is provided with a stepped connecting block 4 connected to it and the diameter of the upper part is larger than that of the lower part. A drill bit 16 is connected to the upper end of the connecting block 4, a workpiece workbench 6 is arranged above the drill bit 16, and a guide rail 7 sliding up and down is arranged on one side of the workpiece workbench 6.

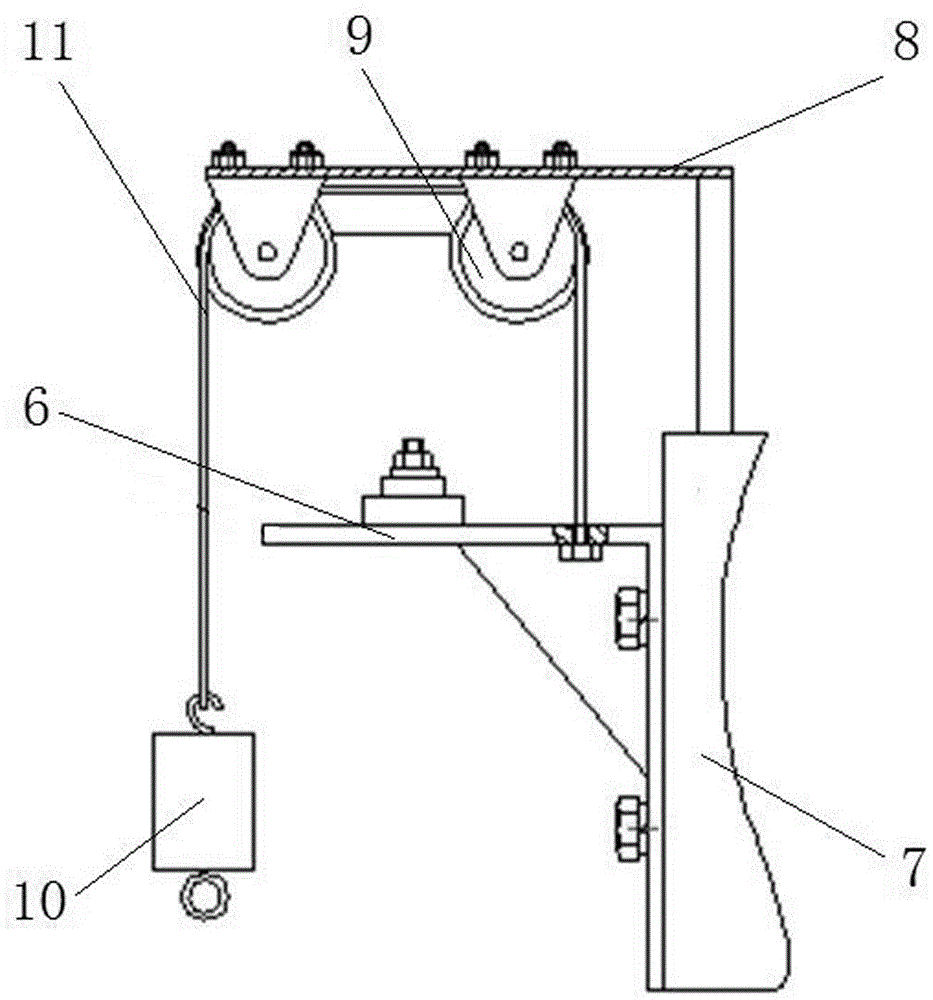

[0017] The top of the guide rail 7 is provided with a horizontal connecting plate 8 connected thereto. The horizontal connecting plate 8 is provided with fixed pulleys 9 distributed left and right, and the two fixed pulleys 9 are provided with one end connected to the right side of the workpiece table 6, and the other end connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com