Height and levelness adjusting method for floating platform

A floating platform and adjustment method technology, applied in the direction of vibration suppression adjustment, measuring devices, instruments, etc., can solve the problems of large test result error, poor stability of floating platform, inaccurate test results, etc., to ensure horizontal accuracy and improve vibration isolation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

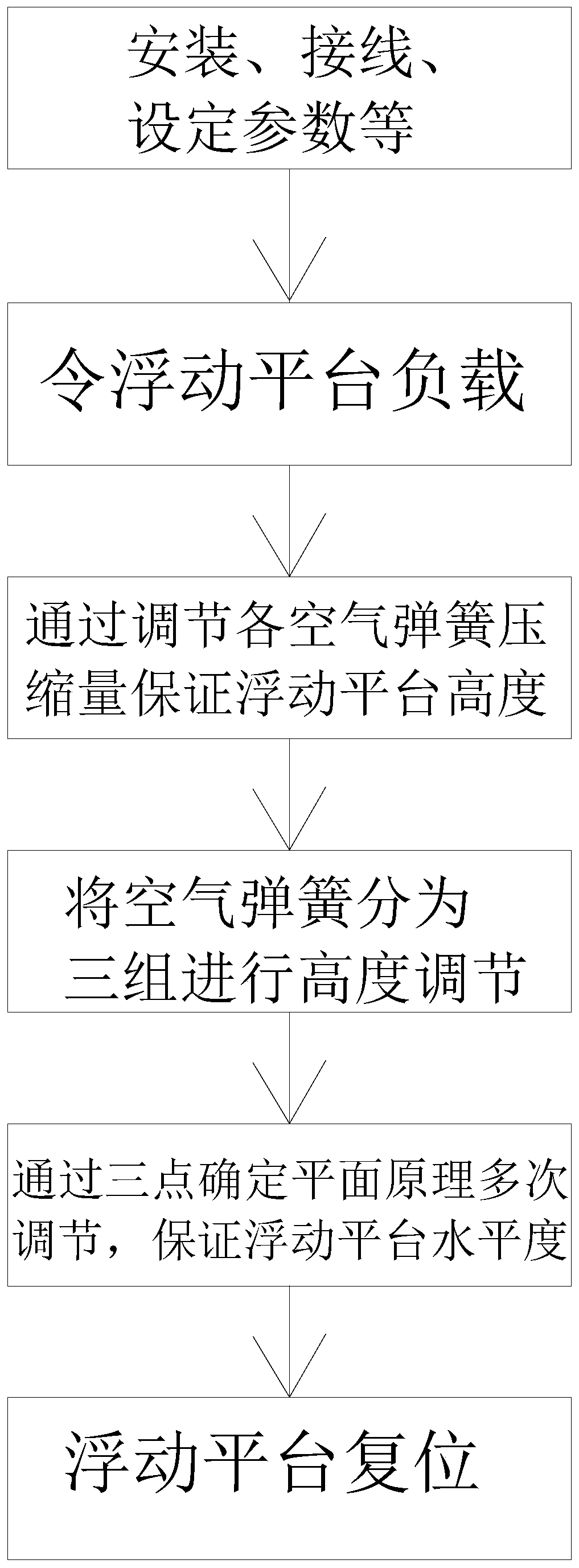

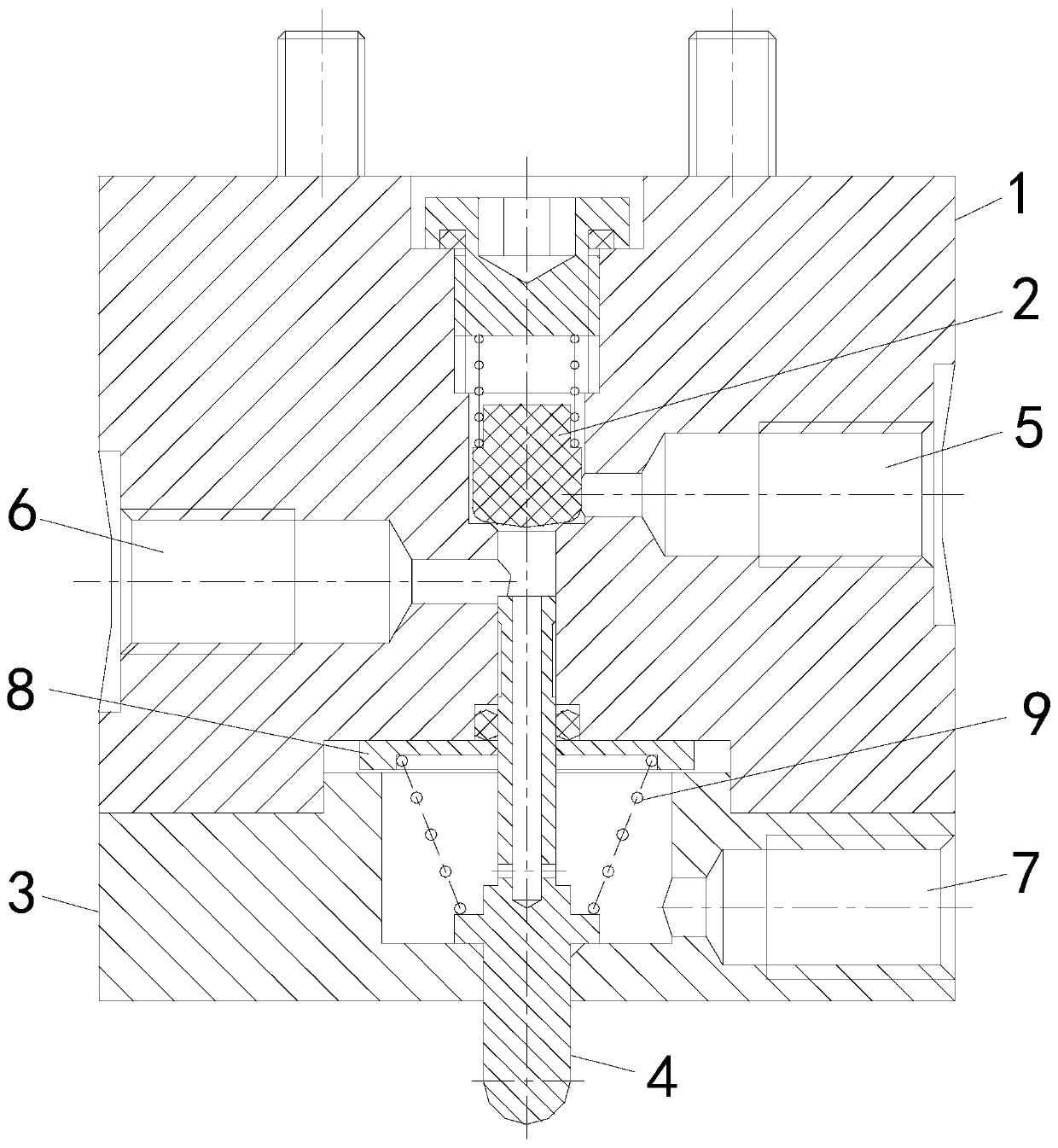

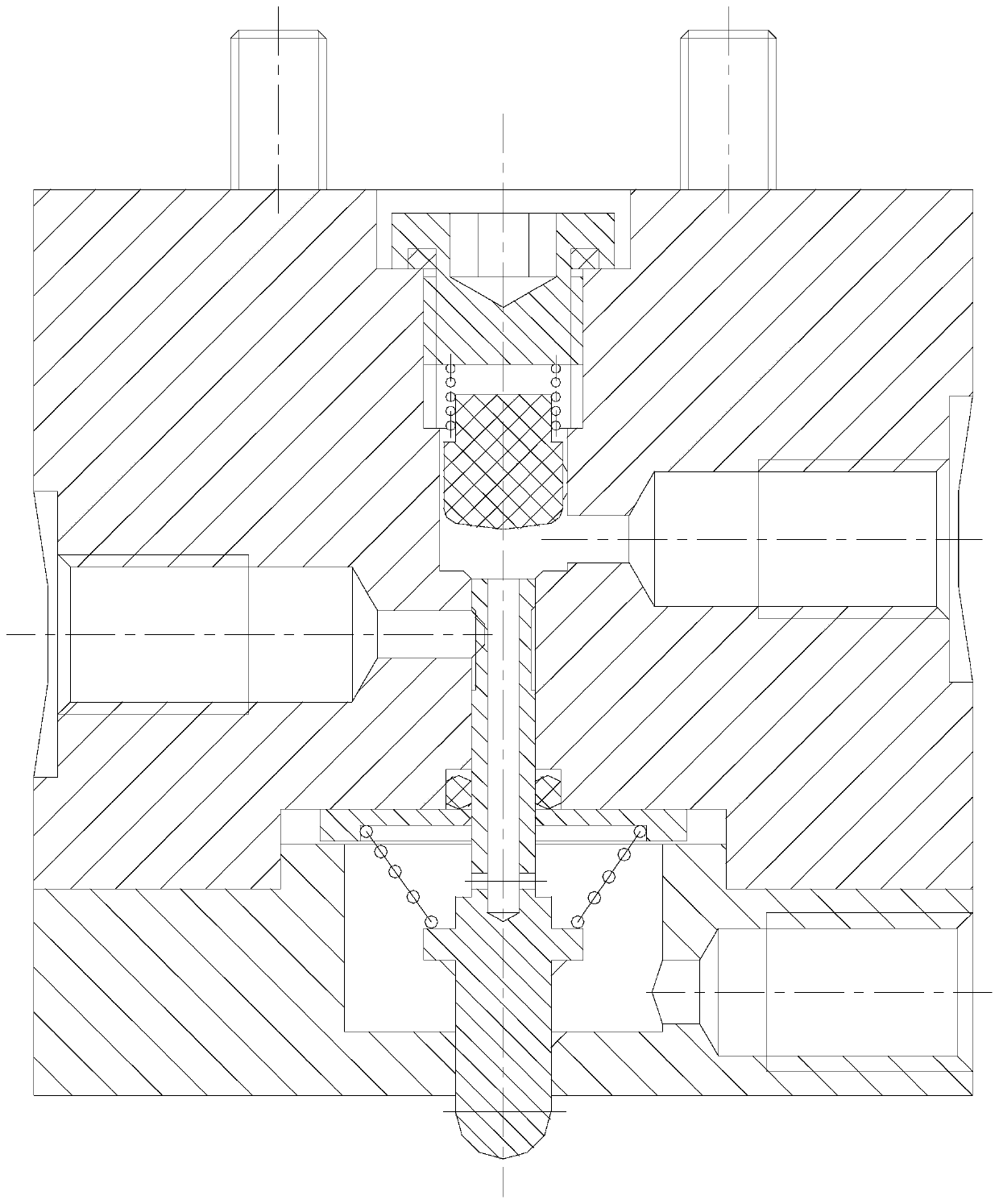

[0027] Example: such as figure 2 with image 3 As shown, a method for adjusting the height and level of a floating platform, including a control system, a number of supports are arranged under the floating platform, and air springs are arranged on the supports, and the air springs are provided with level adjustment valves. The horizontal regulating valve includes a valve body 1, a first cavity is set in the middle of the valve body 1, a main valve core 2 is set in the first cavity, a bonnet 3 is set at the lower end of the valve body 1, and a second cavity is set in the middle of the bonnet 3, The second cavity is provided with a control spool 4, the first cavity is communicated with the second cavity, the inside of the control spool 4 is connected with the first cavity and the second cavity, and the lower end of the control spool 4 is at rest. In the state, the lower end of the protruding valve cover 3 is set, and the upper end of the control valve core 4 is set in the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com