Space constant-temperature large-size printing platform 3D printing device

A printing platform and 3D printing technology, applied in lighting devices, lighting devices, processing platforms/substrates, etc., can solve the problem of inability to ensure uniform and constant temperature in the molding space, uneven heating and cooling of the heating system, and increased internal stress changes in the model and other issues to achieve the effect of improving printing efficiency, ensuring the same level of accuracy, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

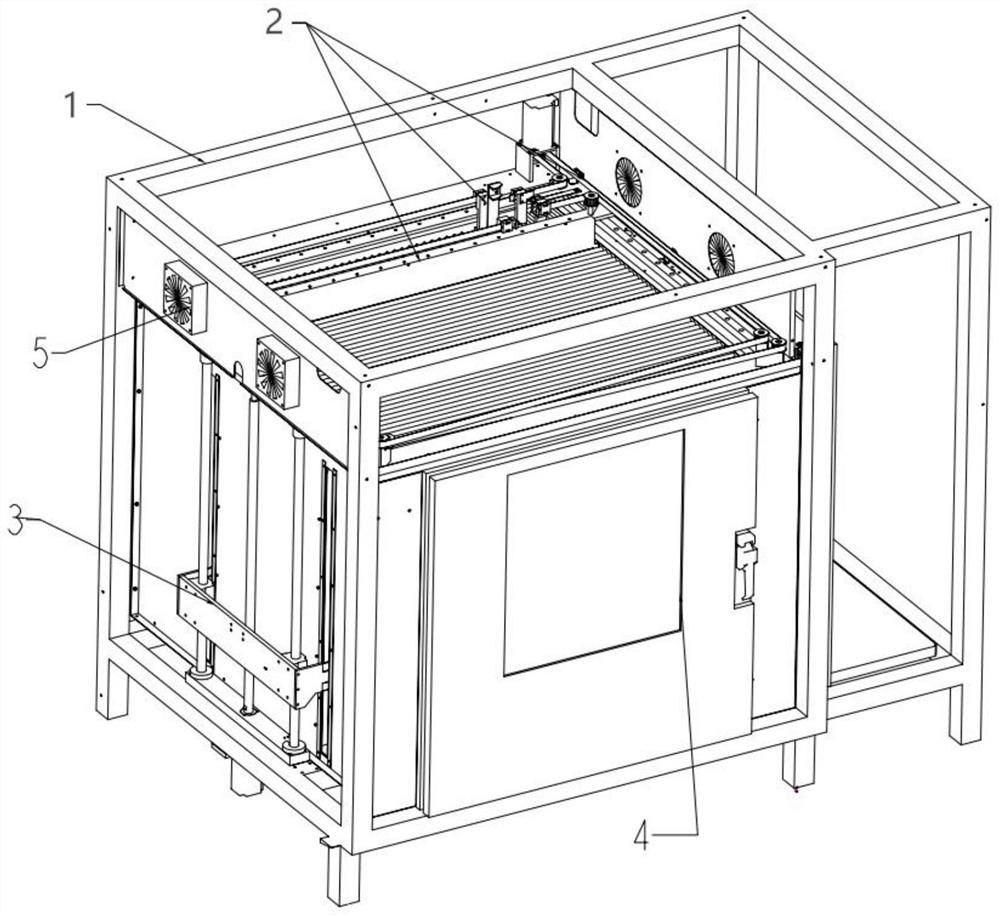

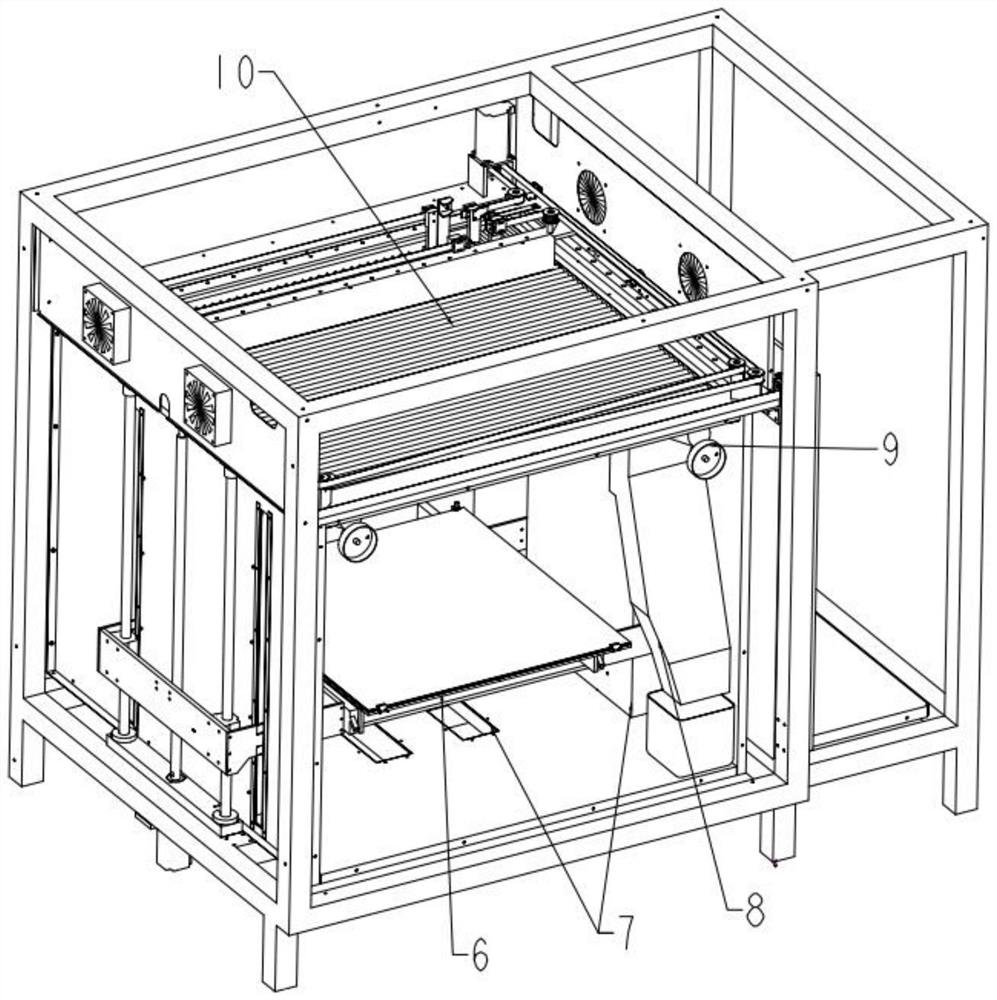

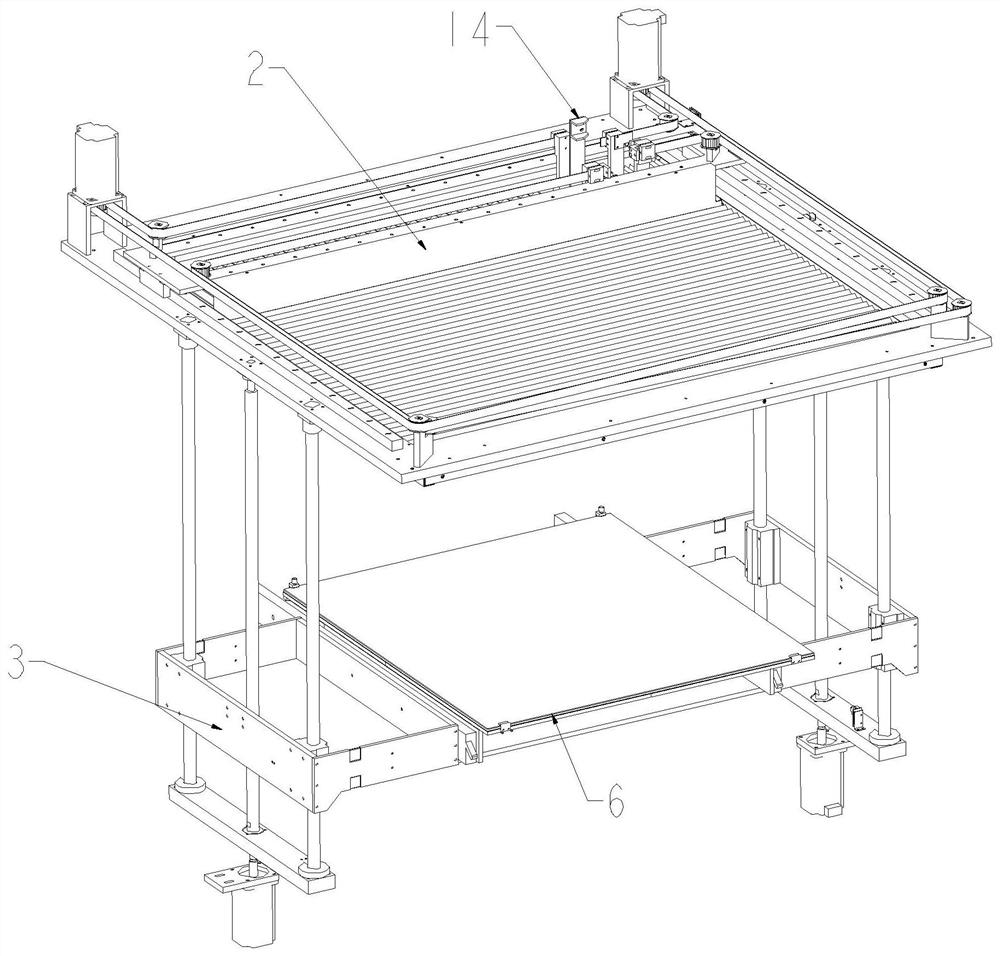

[0037] Such as Figure 1 to Figure 3 As shown, a large-scale printing platform 3D printing device with constant temperature in space includes a frame 1 of the device, and an insulation layer is provided around and on the bottom of the frame 1. The insulation layer can be composed of sheet metal and heat insulation cotton. The front of 1 is provided with front door 4, is provided with three-axis motion mechanism on frame 1, and the X, Y axis motion assembly 2 of three axis motion mechanism is arranged on the top of frame 1, is also provided with on X, Y axis motion assembly 2 The telescopic thermal insulation part 10 and the Z-axis motion component 3 are arranged on the outer side of the thermal insulation layer. The thermal insulation layer, the telescopic thermal insulation component 10 and the cavity surrounded by the front door form a molding space. The printing platform assembly 6 and the nozzle assembly 14 are arranged in the molding space. As well as the hot air double-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com