A large format laser cutting machine

A laser cutting machine and large-format technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the time-consuming and labor-intensive problems that laser cutting equipment cannot complete cutting at one time, and it is difficult to ensure the docking accuracy of multiple sets of laser cutting equipment, etc. Problems, to achieve the effect of easy installation, disassembly and replacement, and ensure horizontal accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

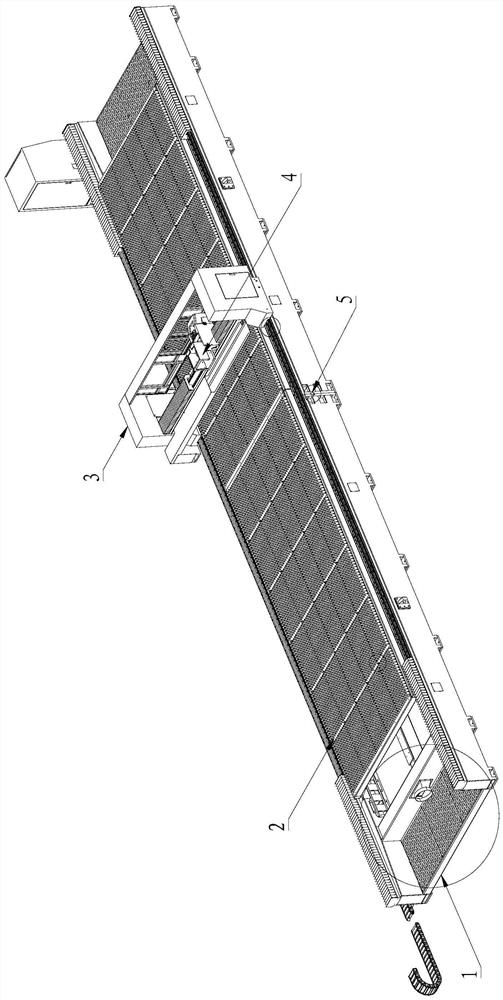

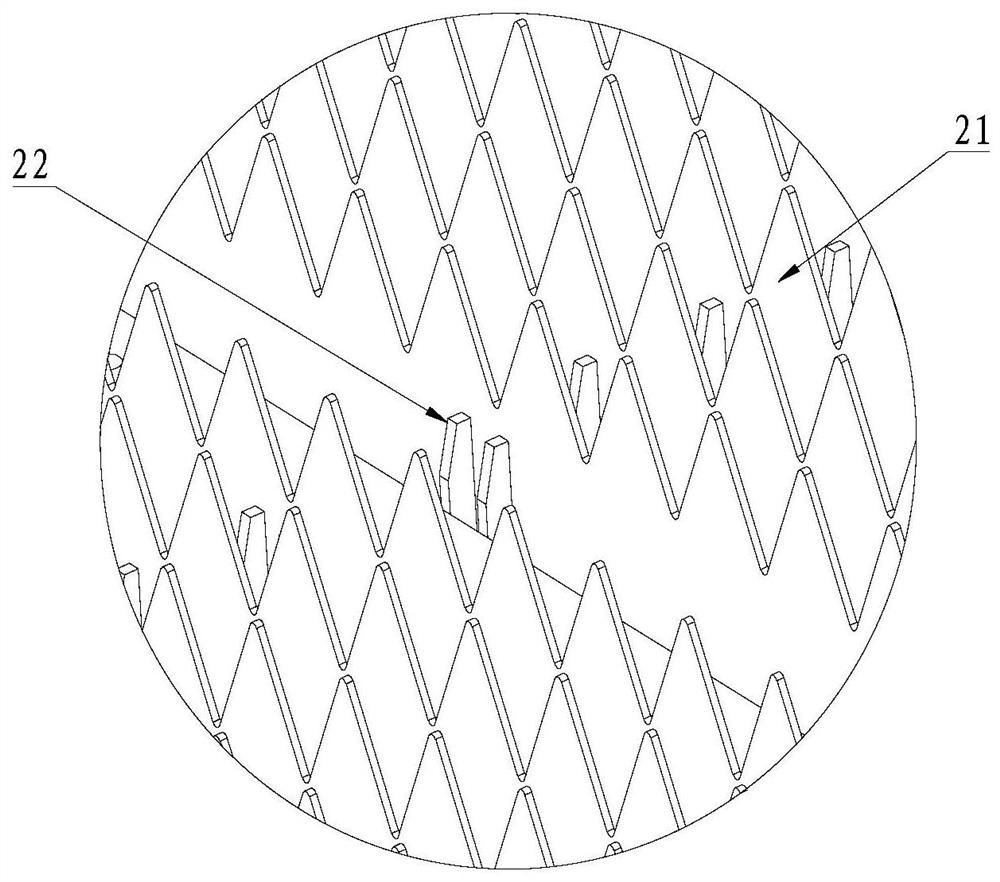

[0071] Please refer to Figure 1 to Figure 13 As shown, Embodiment 1 of the present invention is: a large-format laser cutting machine, including a machine tool 1 and a racking mechanism 2, a gantry mechanism 3, a cutting mechanism 4, a positioning mechanism, and a partition mechanism respectively arranged on the machine tool 1. Thermal mechanism 6 and dust removal mechanism 7;

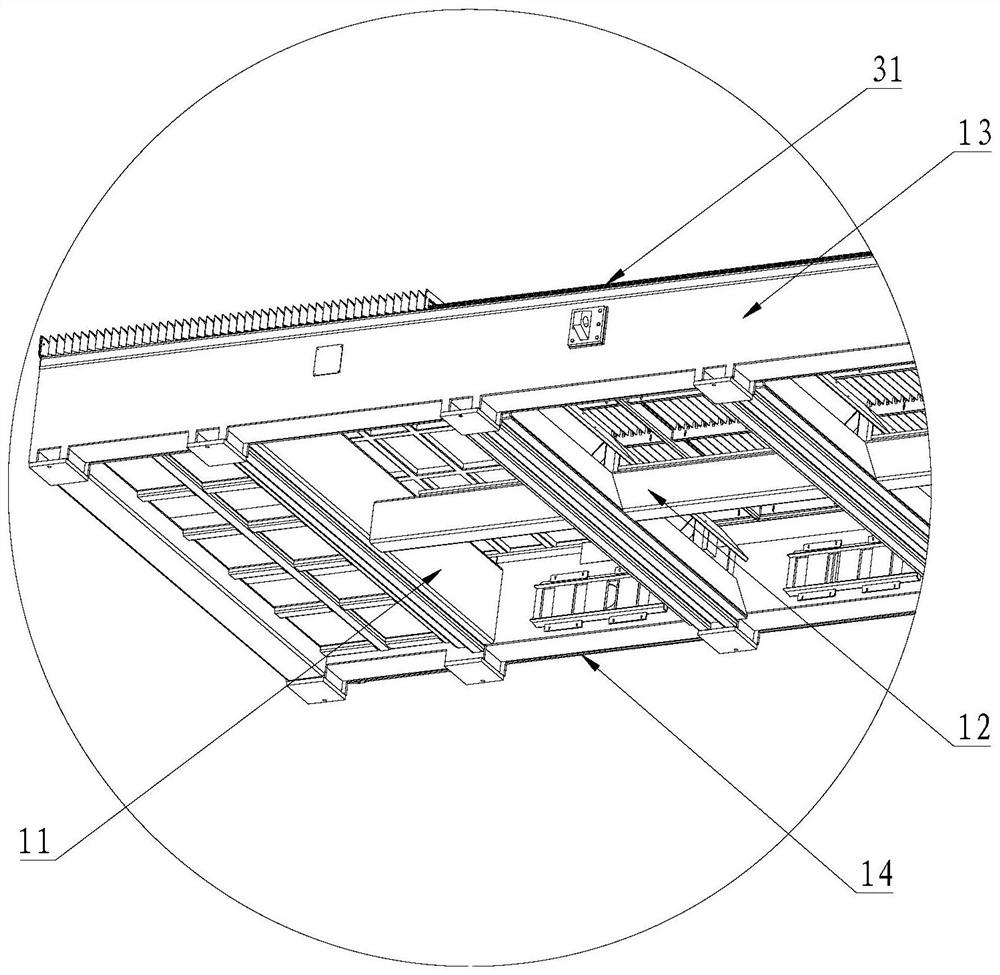

[0072] The frame includes a main beam 11, a main longitudinal beam 12, a first side beam 13 and a second side beam 14, two or more of the main beams 11 are arranged at intervals along the first horizontal direction, the main longitudinal beam 12, the second side beam The side beam 13 and the second side beam 14 are arranged along the second horizontal direction perpendicular to the first horizontal direction, the main longitudinal beam 12 is erected on the main beam 11, and the two ends of the main beam 11 are respectively connected to The first side beams 13 and the second side beams 14 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com