A processing technology for eliminating the time difference of milling plane when the equipment has positioning error

A technology of positioning error and processing technology, applied in milling machine equipment, metal processing equipment, details of milling machine equipment, etc., can solve the problem of accuracy reduction and other problems, and achieve the effect of ensuring horizontal accuracy and no step difference in hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of processing technology of the present invention eliminates the time difference of milling plane when the equipment has positioning error, comprising the following steps:

[0026] a) Select a high-precision four-axis linkage full-closed-loop horizontal machining center, and adopt cutterheads and blades;

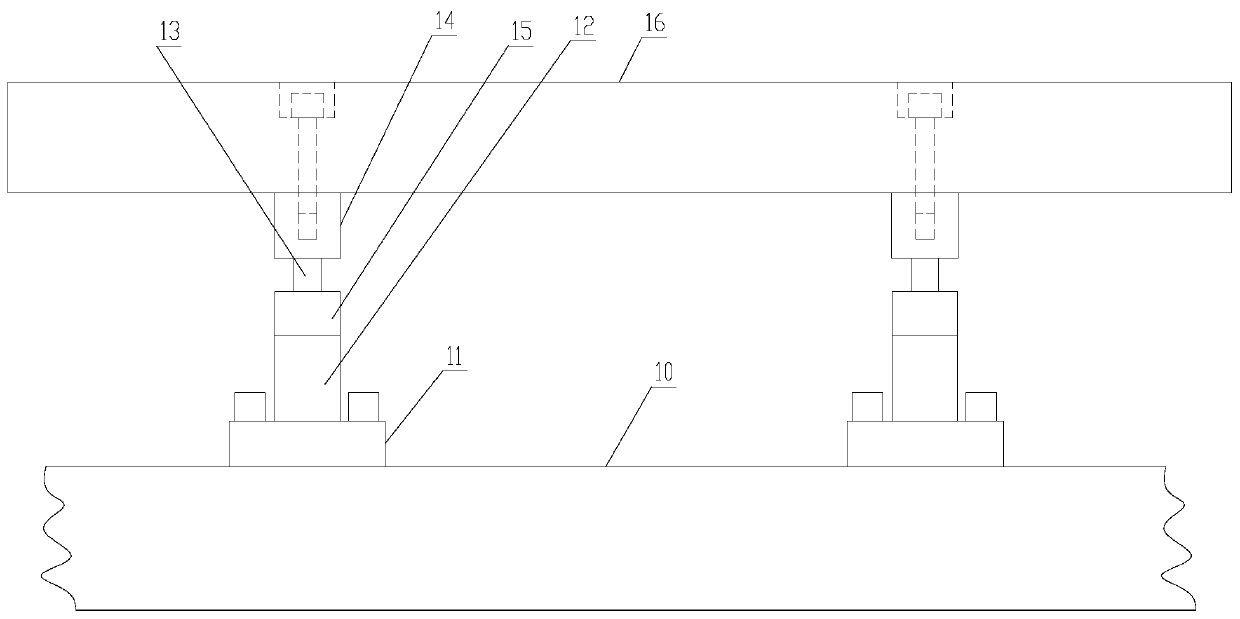

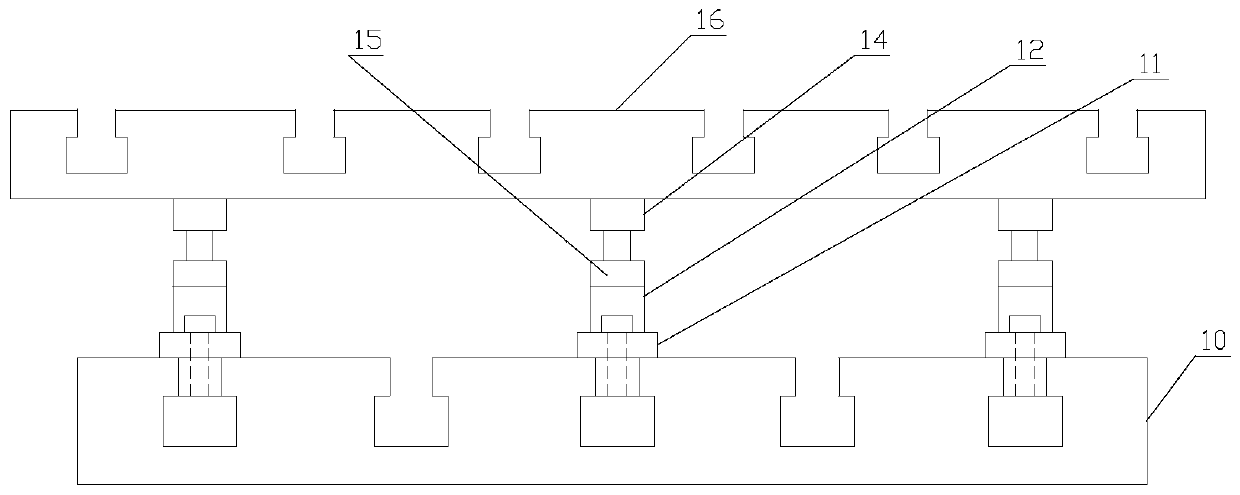

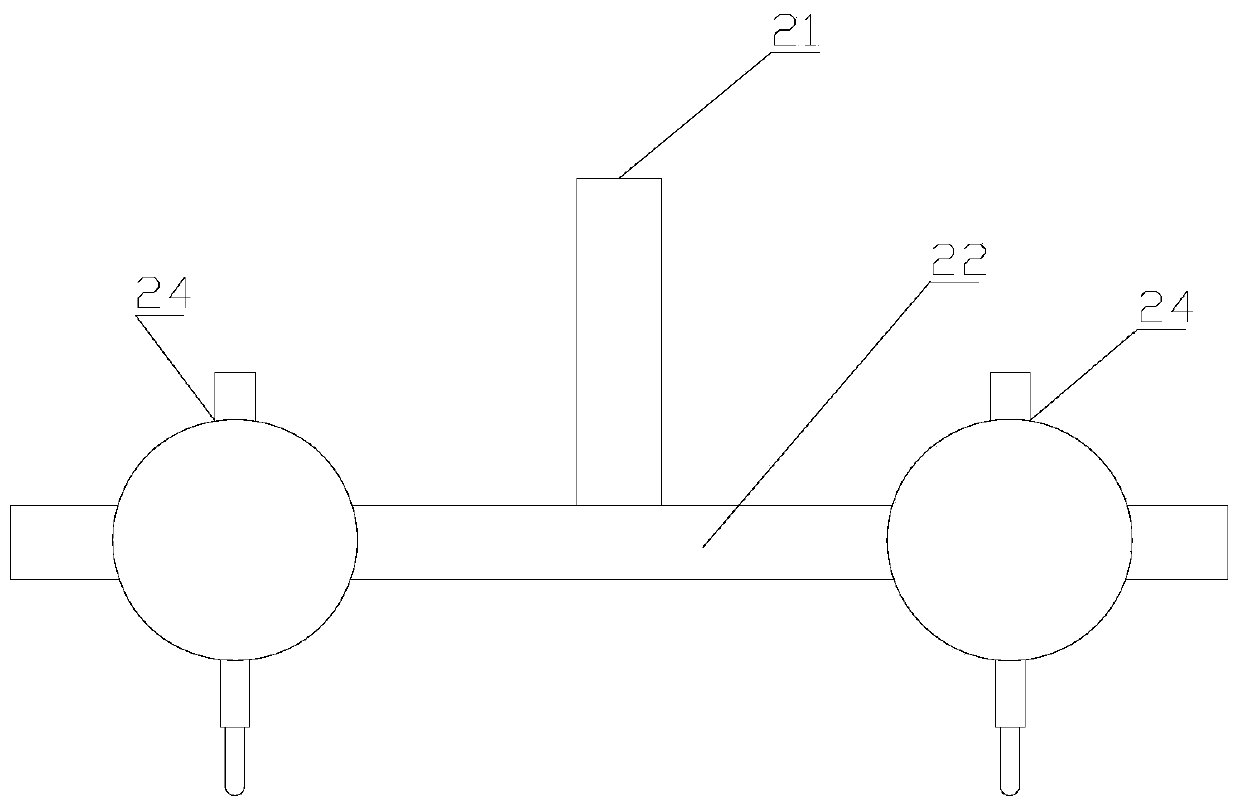

[0027] b) Workpiece fixing platform installation and leveling: fix several support mechanisms on the workbench 10 of the horizontal machining center through fastening bolts, and then use the leveling mechanism to make the end of the support mechanism away from the workbench 10 on the same plane, and then pass Fasten the bolts to fix the workpiece fixing table on the support mechanism, and then fix the workpiece on the workpiece fixing table 16 through the pressing plate. The leveling mechanism includes a mandrel 21, a cross bar 22, two sliding mechanisms 23 and two thousand points Table 24, the lower end of the mandrel 21 is provided with a cross bar 22, the ...

Embodiment 2

[0033] A kind of processing technology of the present invention eliminates the time difference of milling plane when the equipment has positioning error, comprising the following steps:

[0034] a) Select a high-precision four-axis linkage full-closed-loop horizontal machining center, and adopt cutterheads and blades;

[0035] b) Workpiece fixing platform installation and leveling: fix several support mechanisms on the workbench 10 of the horizontal machining center through fastening bolts, and then use the leveling mechanism to make the end of the support mechanism away from the workbench 10 on the same plane, and then pass Fasten the bolts to fix the workpiece fixing table on the support mechanism, and then fix the workpiece on the workpiece fixing table 16 through the pressing plate. The leveling mechanism includes a mandrel 21, a cross bar 22, two sliding mechanisms 23 and two thousand points Table 24, the lower end of the mandrel 21 is provided with a cross bar 22, the ...

Embodiment 3

[0041] a) Select a high-precision four-axis linkage full-closed-loop horizontal machining center, and adopt cutterheads and blades;

[0042] b) Workpiece fixing platform installation and leveling: fix several support mechanisms on the workbench 10 of the horizontal machining center through fastening bolts, and then use the leveling mechanism to make the end of the support mechanism away from the workbench 10 on the same plane, and then pass Fasten the bolts to fix the workpiece fixing table on the support mechanism, and then fix the workpiece on the workpiece fixing table 16 through the pressing plate. The leveling mechanism includes a mandrel 21, a cross bar 22, two sliding mechanisms 23 and two thousand points Table 24, the lower end of the mandrel 21 is provided with a cross bar 22, the cross bar 22 on both sides of the mandrel 21 is respectively provided with a sliding mechanism 23, and the sliding mechanism 23 is provided with a dial gauge 24, so The sliding mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com